A device for collecting gas inside a screw-type sealed container

A technology for sealing containers and internal gas, applied in the field of testing, can solve problems such as gas collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

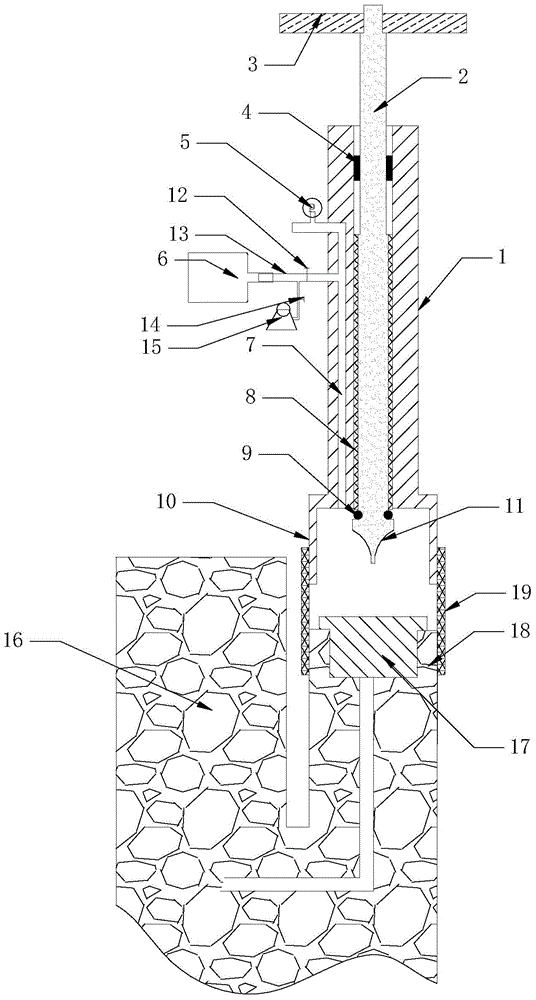

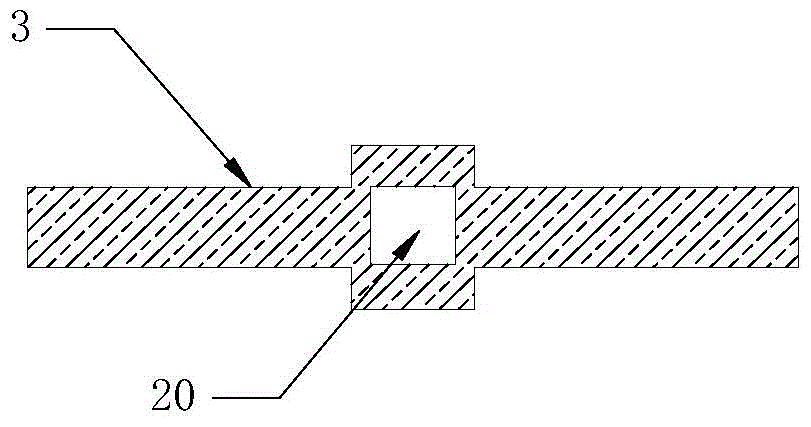

[0009] Such as figure 1 Shown is a schematic diagram of the assembly of the gas collection device of the present invention when in use. The lower end portion 10 of the sleeve 1 is connected to the threaded rod 18 of the container 16 via a rubber tube 19 . Then open the first gas path valve 12 and the second gas path valve 14, open the small vacuum pump 15, and when the value of the pressure gauge 5 is close to 0, continue vacuuming for 10min, then close the second gas path valve 14 and the small vacuum pump 15, Wait for 10 minutes to observe the value change of pressure gauge 5. When the value of the pressure gauge 5 remains unchanged, close the first gas path valve 12 . Turn the handle 3 to move the inner screw 2 downward until the flat mouth of the lower end part 11 of the inner screw enters the groove on the upper surface of the screw plug 17, and then reversely turn the handle 3 until the screw plug 17 withdraws from the screw hole rod 18. Then continue to reversely tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com