Rolling bearing vibration performance reliability variation process detection method and rolling bearing vibration performance reliability variation process detection device

A rolling bearing and process detection technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the variation process that cannot predict the performance reliability of rolling bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

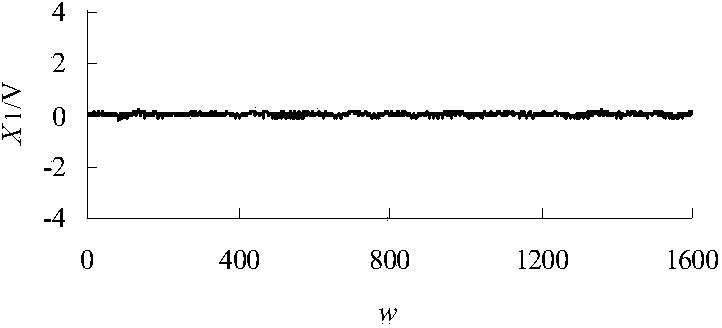

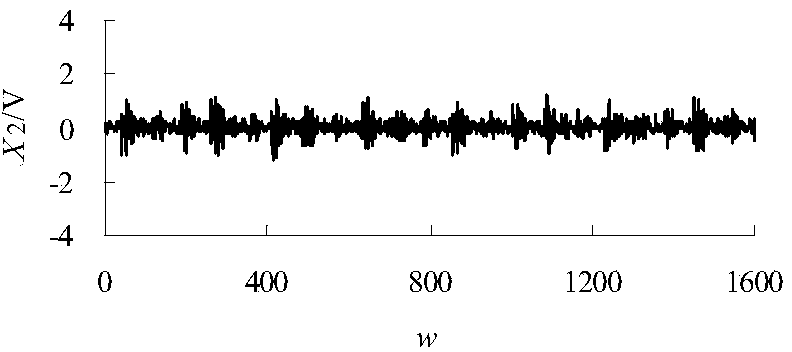

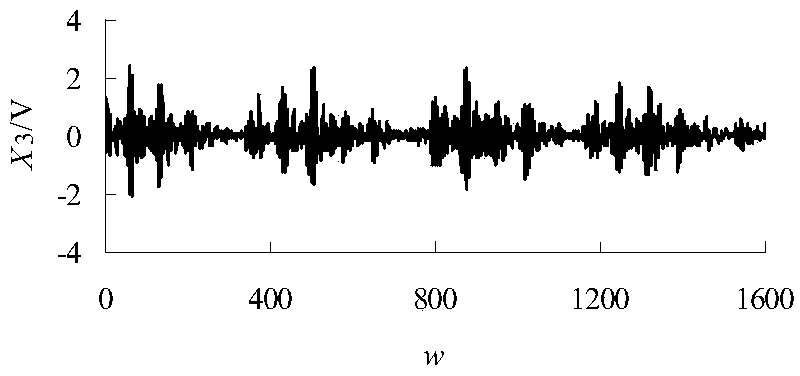

[0132] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0133] Firstly, according to the prior failure experiment, the threshold ±c of the bearing vibration performance is obtained. , the threshold is obtained through experiments, and the corresponding threshold is different according to the selected damage site and sensor.

[0134] Define the time variable as τ. In 1 evaluation period T, from different times τ=τ L Start timing until time τ=τ U End timer. Take the time interval Δτ=τ U -τ L =T is a constant with a very small value, and the subscript i is used to indicate the time interval under different time τ, forming a short time interval sequence:

[0135] ΔΓ=(Δτ 1 ,Δτ 2 ,…,Δτ i ,…,Δτ I );i=1,2,...,I(1)

[0136] In the formula, Δτ i is the i-th time interval, I is the number of time intervals, and T is the evaluation period.

[0137] Assuming that in the i-th time interval, a time interval sequence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com