A Wiring Mechanism for Easy Alignment

A convenient, box-based technology, applied in the direction of electrical components, etc., can solve the problems of strengthening the work strength of operators, inconvenient docking of bolts and junction boxes, and increasing the difficulty of junction boxes, so as to reduce labor intensity, shorten operation time, and reduce procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

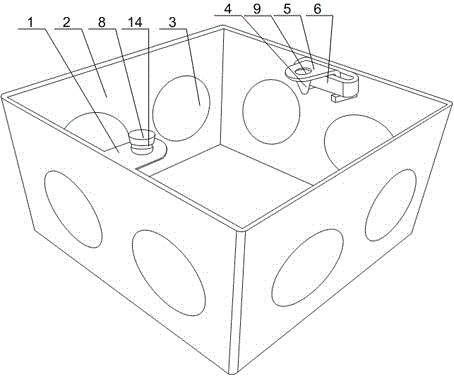

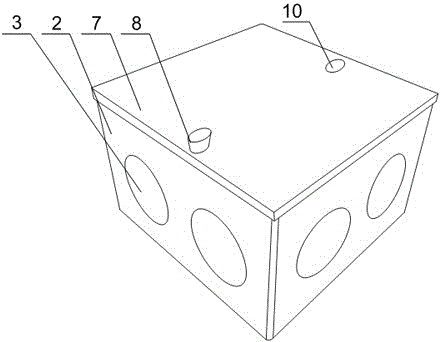

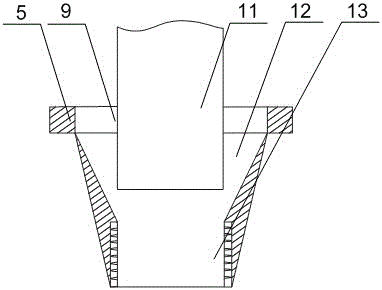

[0023] Such as Figure 1 to Figure 4 As shown, this embodiment includes a box body 2 with one end open and a cover plate 7 matched with the box body 2, and a fixed part 1 and a movable cavity are respectively installed on a group of mutually parallel sides of the open part of the box body 2. 6. There is a through hole on the fixed part 1, and the end of the rotating body 8 is threadedly matched with the through hole. In the cavity 6, the movable part 5 is provided with a correction hole 9 whose aperture is larger than the aperture of the through hole, and the lower end of the correction hole 9 is connected with an extension part 4, and the inside of the extension part 4 is provided with a tapered cavity and a screw thread connected to each other. A through hole 13, and the tapered cavity communicates with the correction hole 9; also includes a screw hole 10 arranged on the cover plate 7 and corresponding to the correction hole 9. During the work of the present invention, the ...

Embodiment 2

[0026] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the middle part of the rotating body 8 is provided with an annular groove 14 , and the cover plate 7 is rotatably arranged in the annular groove 14 . One end of the cover plate 7 is set on the rotating body 8 by turning, and is set on the fixed part 1 together with the rotating body 8, so that the cover plate 7 can move relative to the box body 2, reducing the need for workers to tighten the bolts 11 The number of times, and facilitate the opening of the cover plate 7 during line maintenance or detection.

Embodiment 3

[0028] Such as figure 1 As shown, this embodiment is based on the embodiment 1, and a plurality of joint holes 3 are opened on the four side walls of the box body 2 , and sealing covers are welded on the joint holes 3 . The installation method of the sealing cover installed on the joint hole 3 is spot welding, that is, the part of the sealing cover is connected to the box body 2 by spot welding to realize the sealing of the joint hole 3. When the box body 2 needs to be connected in any direction around the When the line pipe is used, the sealing cover is directly taken out, and the box body 2 is connected with the line pipe through a straight pipe or an elbow joint, so as to improve the practicability of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com