Storage battery and preparation method thereof

A battery and battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of increasing the manufacturing of metal parts and welding man-hours, not being well solved, and increasing the amount of welding metal, so as to reduce the cost of manufacturing man-hours, Eliminates current path bottlenecks and increases productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

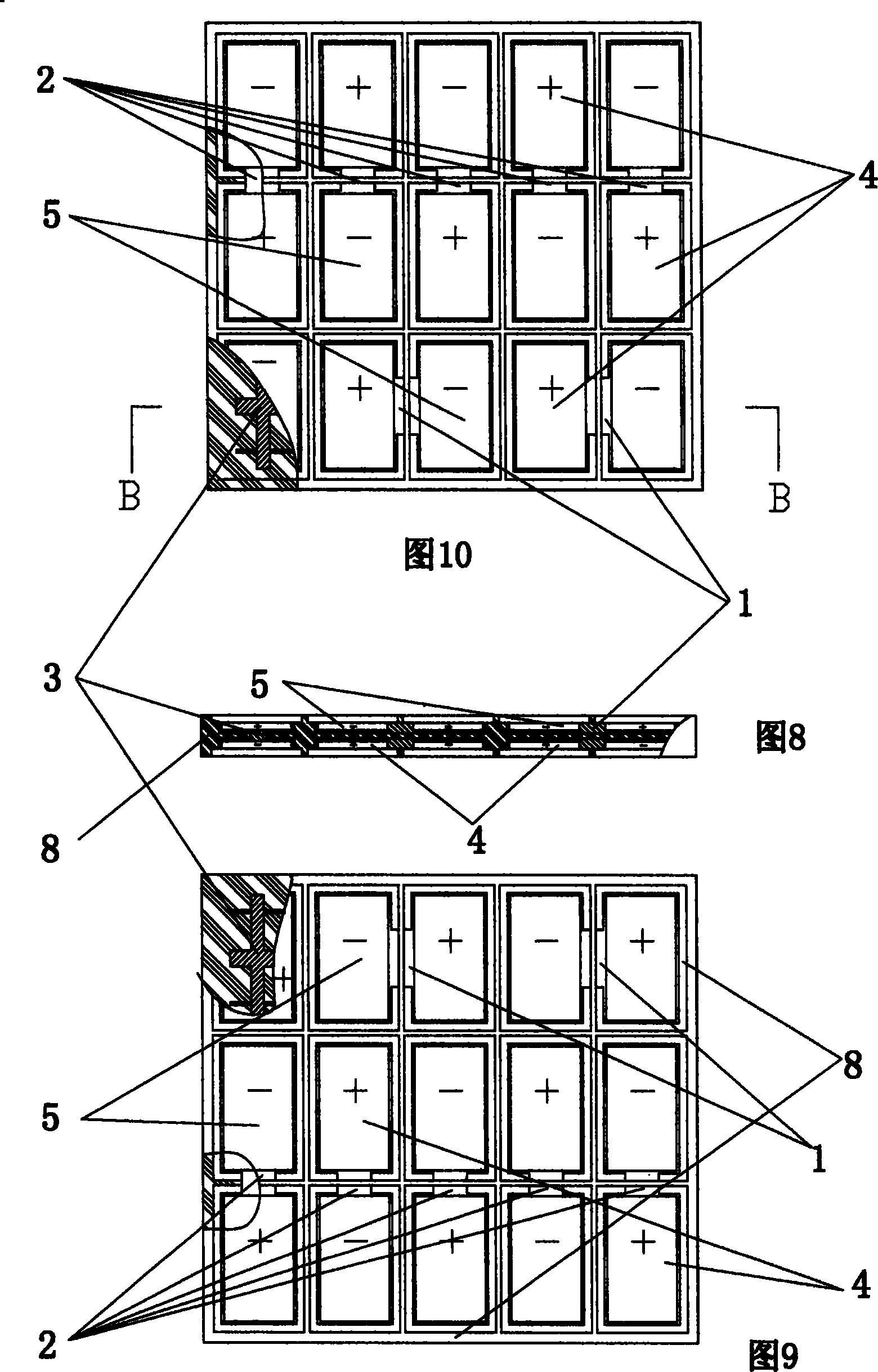

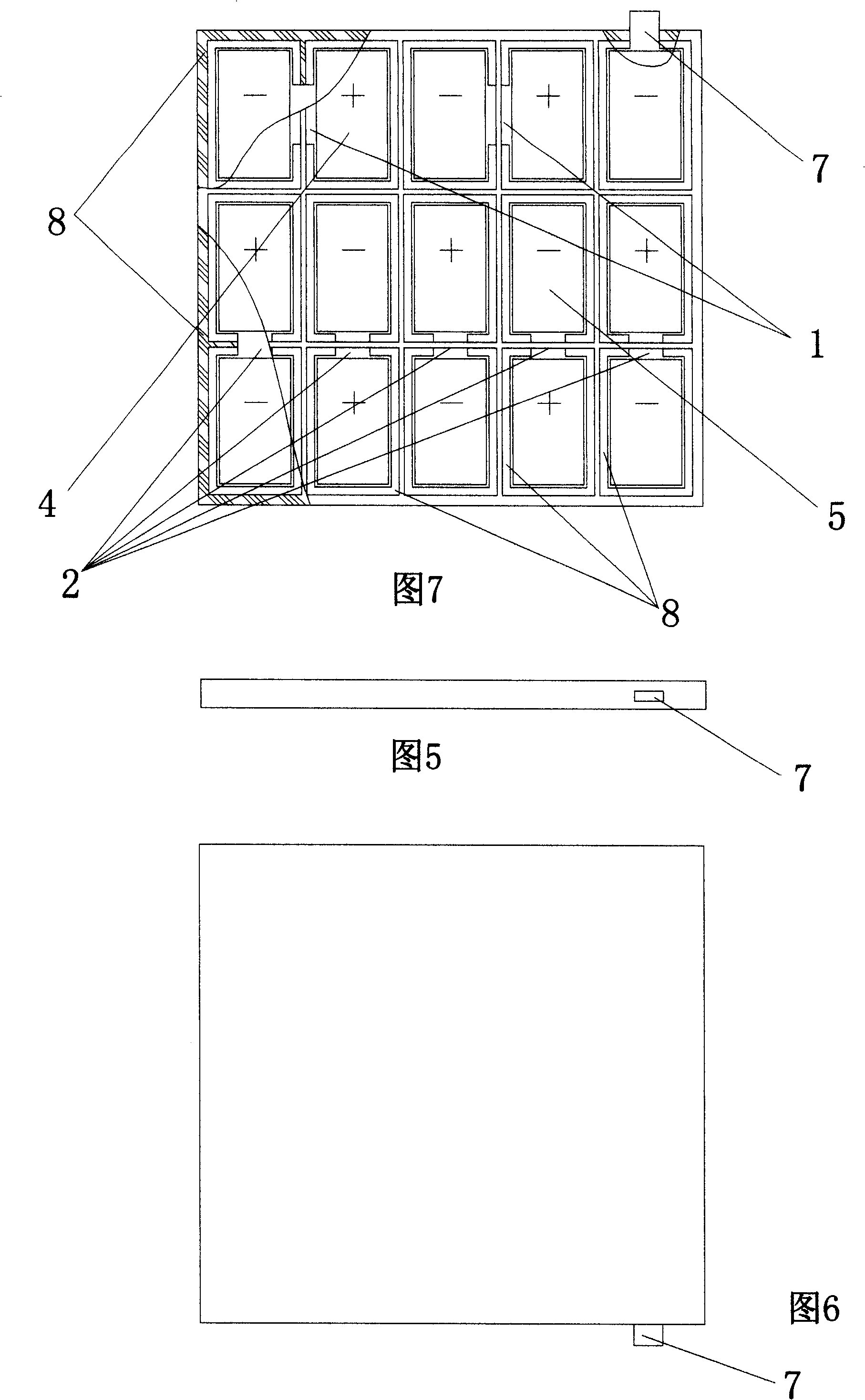

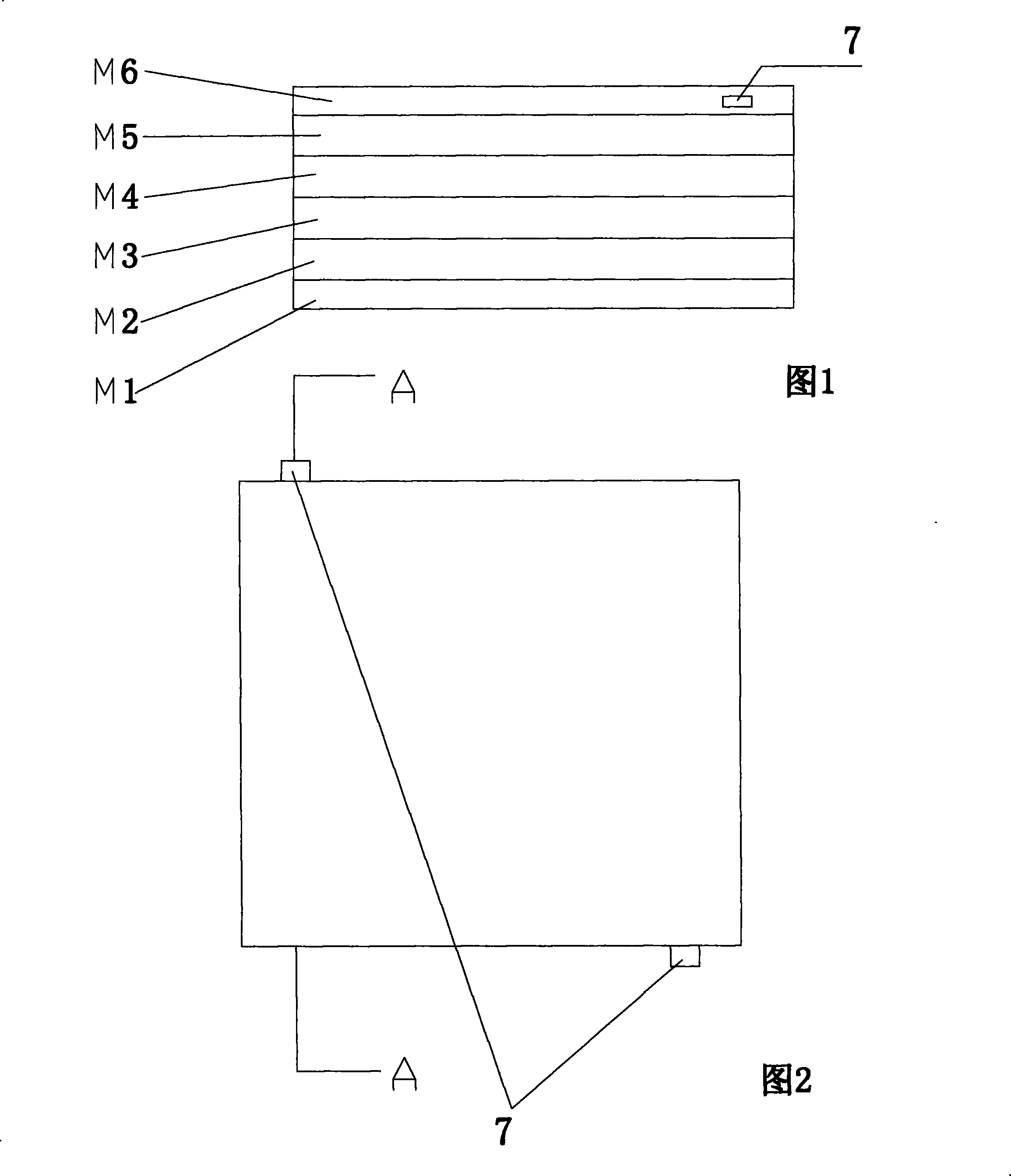

[0067] A storage battery consisting of 3×5×5 unit cells, each unit cell is a cuboid structure composed of positive plates, separators, and negative plates stacked in sequence, and then filled and packaged with polymer materials, each unit cell and its surroundings The unit cells are connected as a whole without gaps; the unit cells are placed tightly in order on a plane parallel to the electrode plate to form a unit cell layer, and at the same time in the direction perpendicular to the electrode plate-defined as the Z axis, constitute 5-layer structure; the direction of each unit cell is exactly opposite to that of the adjacent unit cell; the positive plate grid of the first unit cell has terminal 7, and the negative plate grid of the first unit cell is connected to the adjacent second plate grid The positive plate grids of the two unit cells are connected as a whole, the negative plate grid of the second unit battery is connected as a whole with the positive plate grid of the ...

Embodiment 2

[0075] A storage battery consisting of 1 × 2 cells, see Figure 11 , Figure 12 , each unit cell is a cuboid structure composed of positive plates, separators, and negative plates stacked in sequence, and then filled and packaged with polymer materials. The two unit cells are connected as a whole without gaps; The parallel planes are arranged tightly in order to form a unit battery layer. The positive plate grid of the first unit battery has a terminal 7, and the negative plate of the first unit battery is connected to the positive plate of the second adjacent unit battery. The horizontal connection grid 1 is connected as a whole, and the negative plate grid of the second unit cell has a terminal.

[0076] The preparation process is divided into module design, grid preparation, module preparation, battery assembly, and battery formation. Module design: take the middle of the positive and negative plates of the unit battery as the boundary, and divide the battery into two-laye...

Embodiment 3

[0082]A hollow "back"-shaped storage battery, each unit cell is a cuboid structure composed of positive plates, separators, and negative plates stacked in sequence, and then filled and packaged with polymer materials, between each unit cell and its surrounding cells There are no gaps connected as a whole; the unit cells are placed tightly in sequence on a plane parallel to the electrode plate to form a unit cell layer, and at the same time in the direction perpendicular to the electrode plate-defined as the Z axis, a 2-layer structure is formed; each The plate direction of the first unit cell and its adjacent unit cell is just opposite; the positive plate grid of the first unit cell has terminal 7, and the negative plate grid of the first unit cell is opposite to that of the second adjacent unit cell. The positive plate grid is connected as a whole, the negative plate grid of the second unit cell is connected as a whole with the positive plate grid of the third adjacent unit ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com