A composite material aircraft fuselage barrel section integral molding die

An aircraft fuselage and integral molding technology, which is applied in the field of aviation mold equipment, can solve the problems of inconvenient operation and use by fixed personnel, long production cycle, and reduced work efficiency, so as to save design and manufacturing costs and the cost of standard rivets, reduce Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

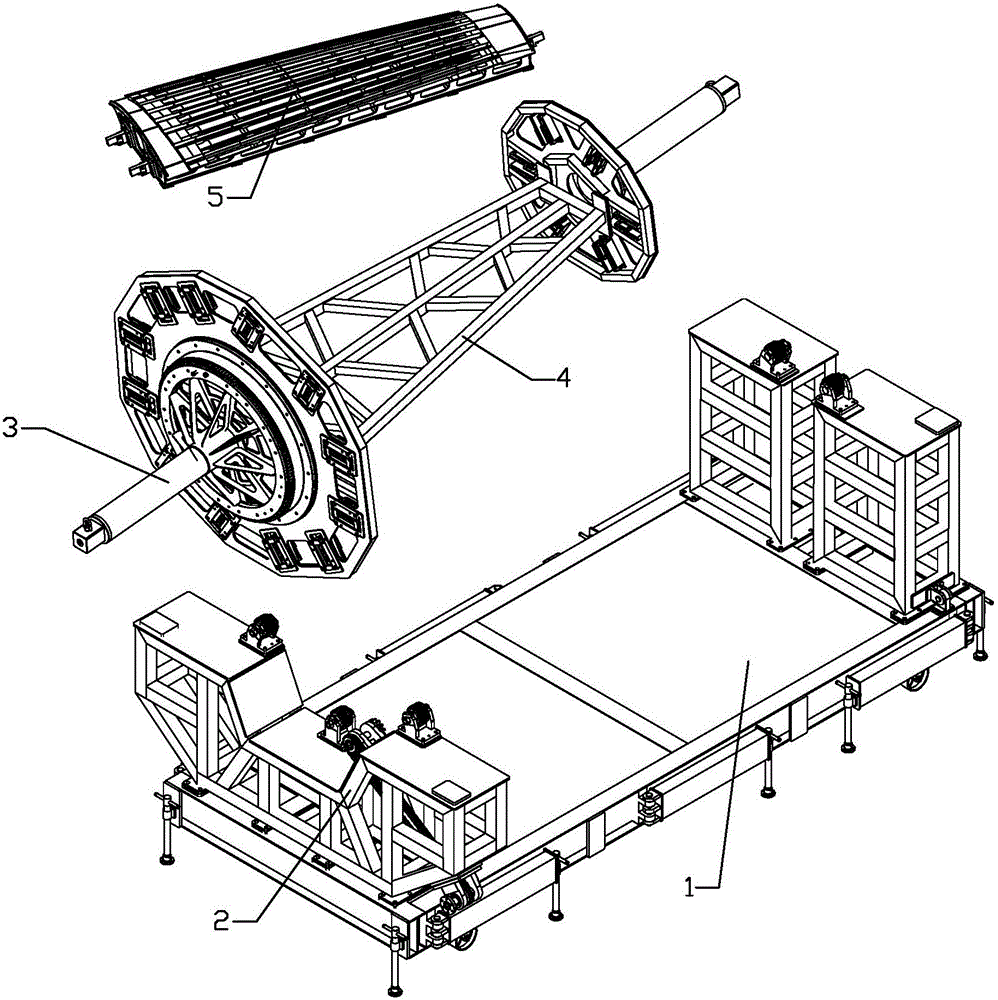

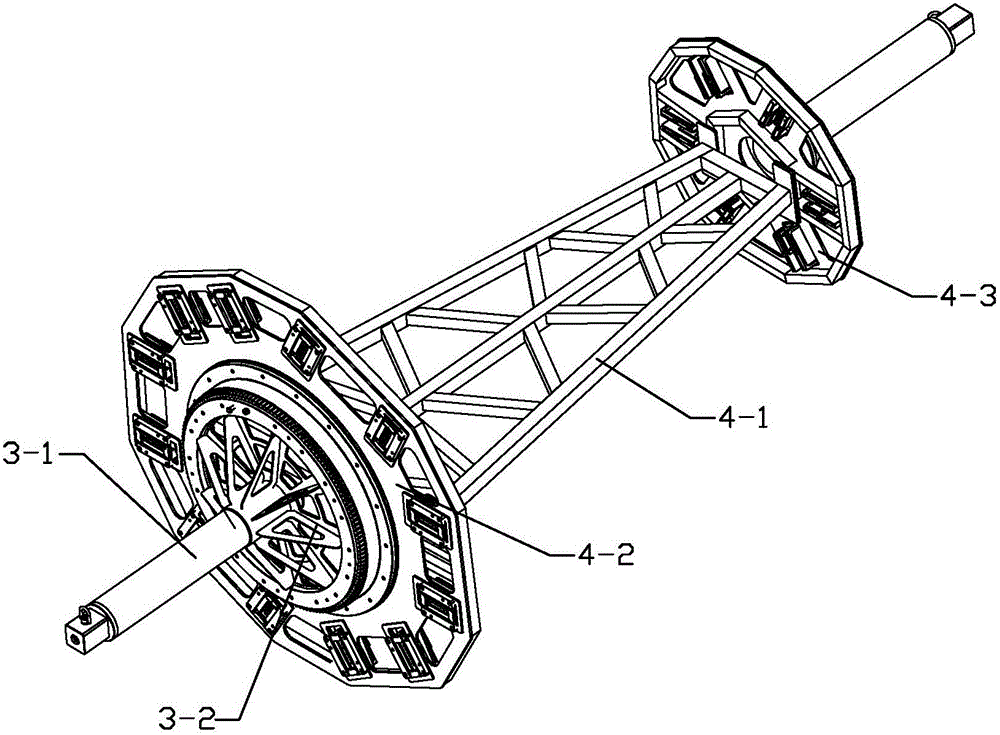

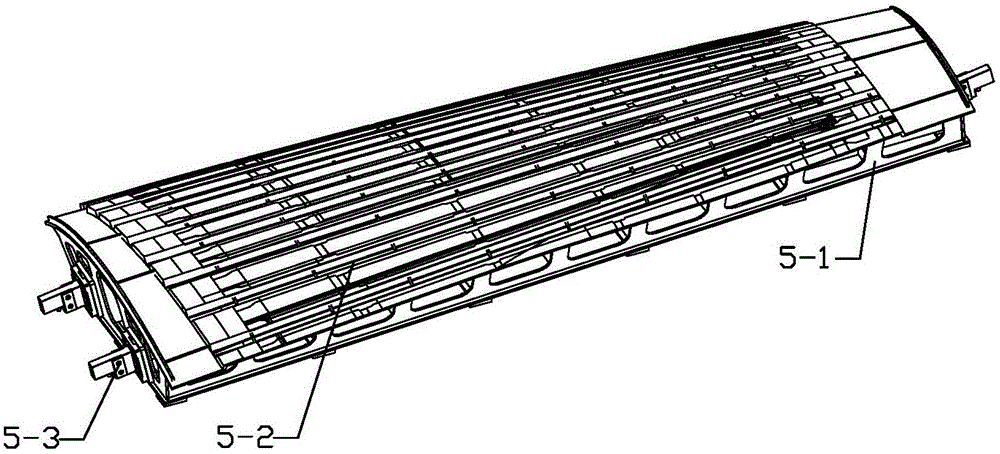

[0009] refer to figure 1 figure 2 image 3 Described a composite material aircraft fuselage section integral forming die, it comprises fixed chassis 1, fixed bracket 2, rotating device 3, support bracket 4, combination module 5, it is characterized in that: described fixed chassis 1 upper top The front and rear edges of the surface are symmetrically fixedly connected with fixed brackets 2, and each of the fixed brackets 2 is equipped with a rotating device 3 on the top surface, and a support bracket 4 is fixedly connected at the center of the circle between the inner top surfaces of the two rotating devices 3. , the surrounding edge of the support bracket 4 is evenly distributed and fixedly connected with several combined modules 5, the upper top surface of the fixed bracket 2 in the front is in a concave shape, and the upper top surface of each of the fixed bracket 2 is fixedly connected with several supporting modules. Rotating shaft, each surface of the upper top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com