Integrally-stamped water-dispensing pipe for pets and method of manufacturing same

A drinking water pipe and integrated technology, which is applied in the field of drinking water pipes and processing the drinking water pipes, can solve the problems of many processing procedures, increased working hours, poor sealing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

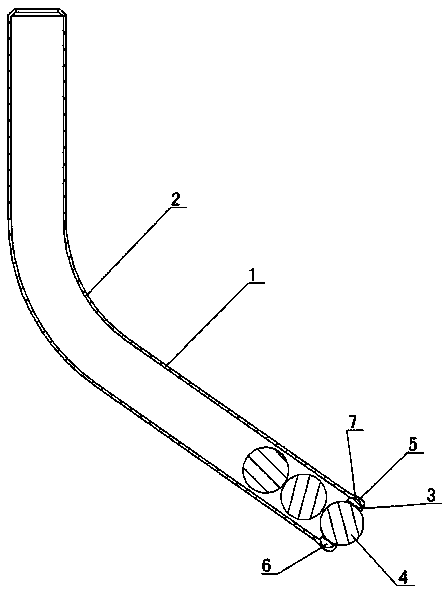

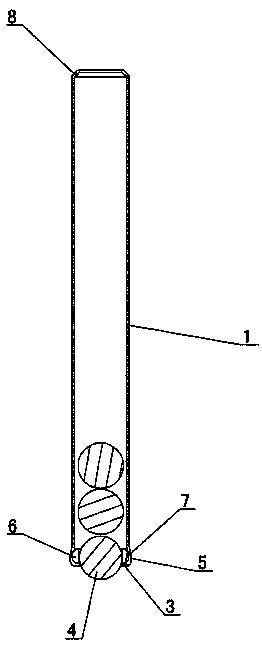

[0019] The invention relates to an integrated stamping pet drinking water pipe, such as figure 1 , figure 2 As shown, it includes a drinking water pipe 1 made of a seamless steel pipe or a seamed steel pipe. The upper end of the drinking water pipe 1 is connected to a drinking water bottle, and the lower end of the drinking water pipe is provided with a drinking water head 3. The drinking water head 3 is provided with an integrally stamped outer The protruding bulge 5 is provided with a sealing ring 6 in the protruding bulge 5 outside, and the steel ball 4 is placed in the water head 3, and the steel ball 4 is in close contact with the sealing ring 6. The main feature of this solution is to use a seamless steel pipe or a seamed steel pipe to make a section of drinking water pipe 1, and then stamp one end of the drinking water pipe into a bulge 5 with an external protrusion through the stamping process, and then set a sealing ring 6 on the inner wall of the bulge. Then put st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com