Track mounted chassis of a combine harvester

A combine harvester and crawler chassis technology, which is applied to the chassis of agricultural machinery, agricultural machinery and implements, and applications. It can solve the problems of troublesome maintenance of load-bearing wheels and the inability to adjust the tension of the crawler in time, so as to achieve fast maintenance and improved Safety and reliability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

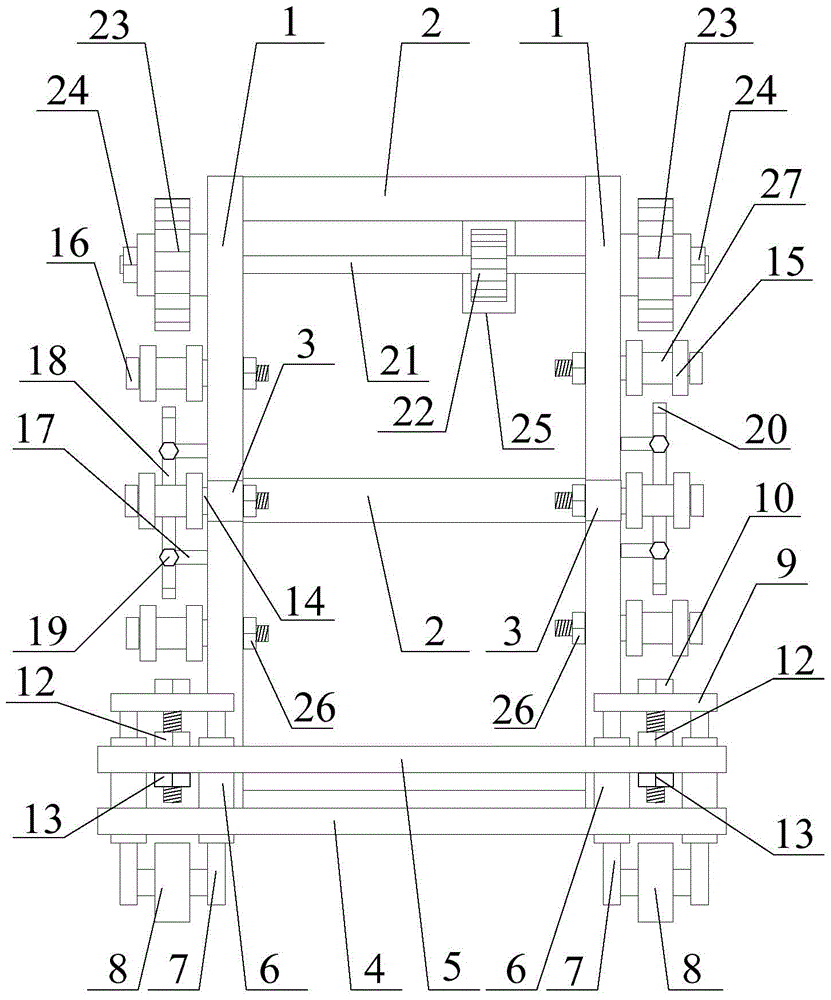

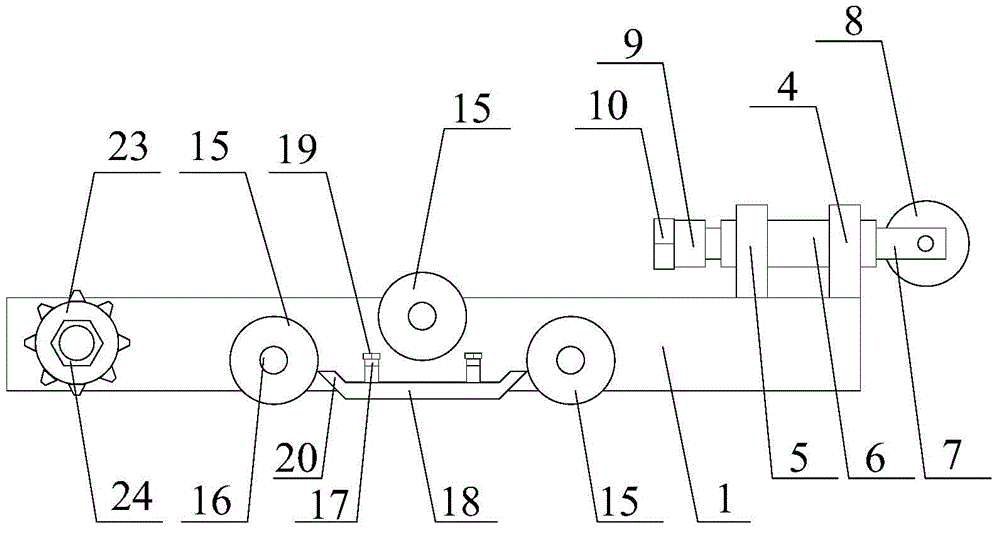

[0016] Such as figure 1 and 2 Shown, the crawler installation chassis of combine harvester of the present invention comprises crawler chassis structure, crawler drive structure and crawler tensioning structure;

[0017] Among them, the crawler chassis structure includes two load-bearing beams 1 parallel to each other, three support beams 2, two support columns 3, load-bearing wheels 15, load-bearing shafts 16 and axle nuts 26; the three support beams 2 are vertically installed on the two load-bearing beams 1, and the distance between two adjacent support beams 2 is equal; two support columns 3 are respectively installed vertically in the middle of the upper sides of the two load-bearing beams 1; A sleeve pipe 14 that vertically runs through the inner and outer sides of the load-bearing beam 1; a sleeve pipe 14 that vertically runs through the inner and outer sides of the support column 3 is also provided at the top of the support column 3; After passing through the sleeve 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com