U-shaped part orientation mechanism

A technology of orientation mechanism and parts, applied in hand-held tools, manufacturing tools, etc., can solve the problems of increasing production energy consumption, increasing the complexity of orientation mechanism, etc., and achieve the effect of fast orientation speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with accompanying drawing:

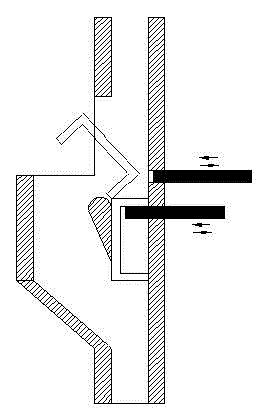

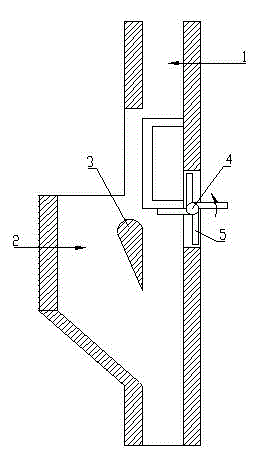

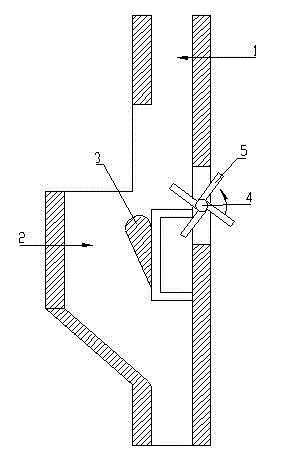

[0018] like Figures 2 to 5 As shown: the U-shaped part orientation mechanism in this embodiment includes a vertically arranged main chute 1 and an auxiliary chute 2 arranged on the main chute, and the two ends of the auxiliary chute 2 are connected to the main chute 1 In communication with each other, a cylinder 3 for turning over U-shaped parts is provided between the auxiliary chute 2 and the main chute 1, and a cylinder 3 is provided on the groove wall of the main chute 1 opposite to the cylinder 3 There is a turning wheel 4, and the circumferential surface of the turning wheel 4 is evenly provided with 4 baffle plates 5 extending radially along the turning wheel. Specifically, the length of the U-shaped part should be greater than the width of the main chute, so as to Ensure that the U-shaped part always moves along its own length in the main chute. In addition, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com