Orienting device for orienting objects

An orientation device and object technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of reducing orientation speed, object detachment, high center of gravity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

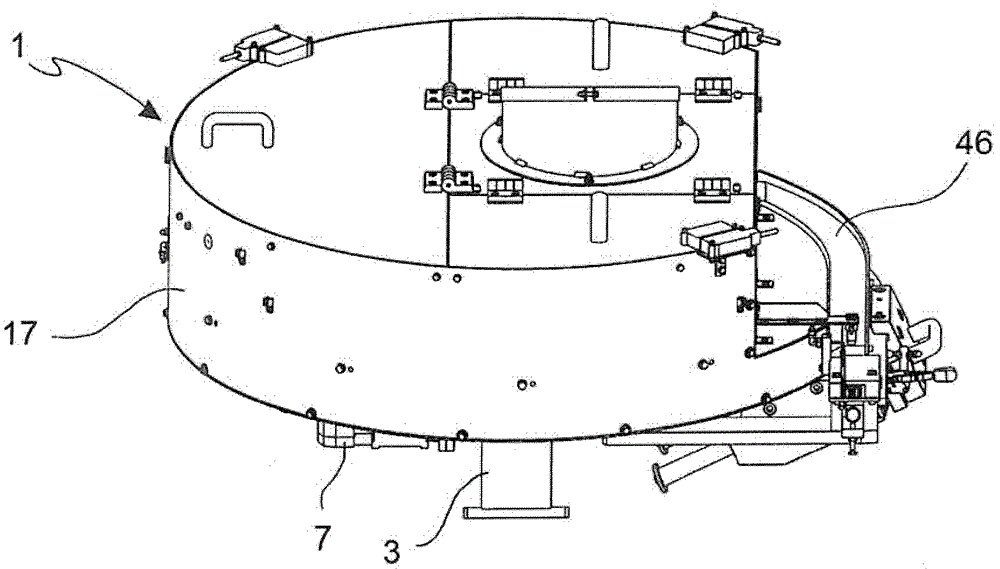

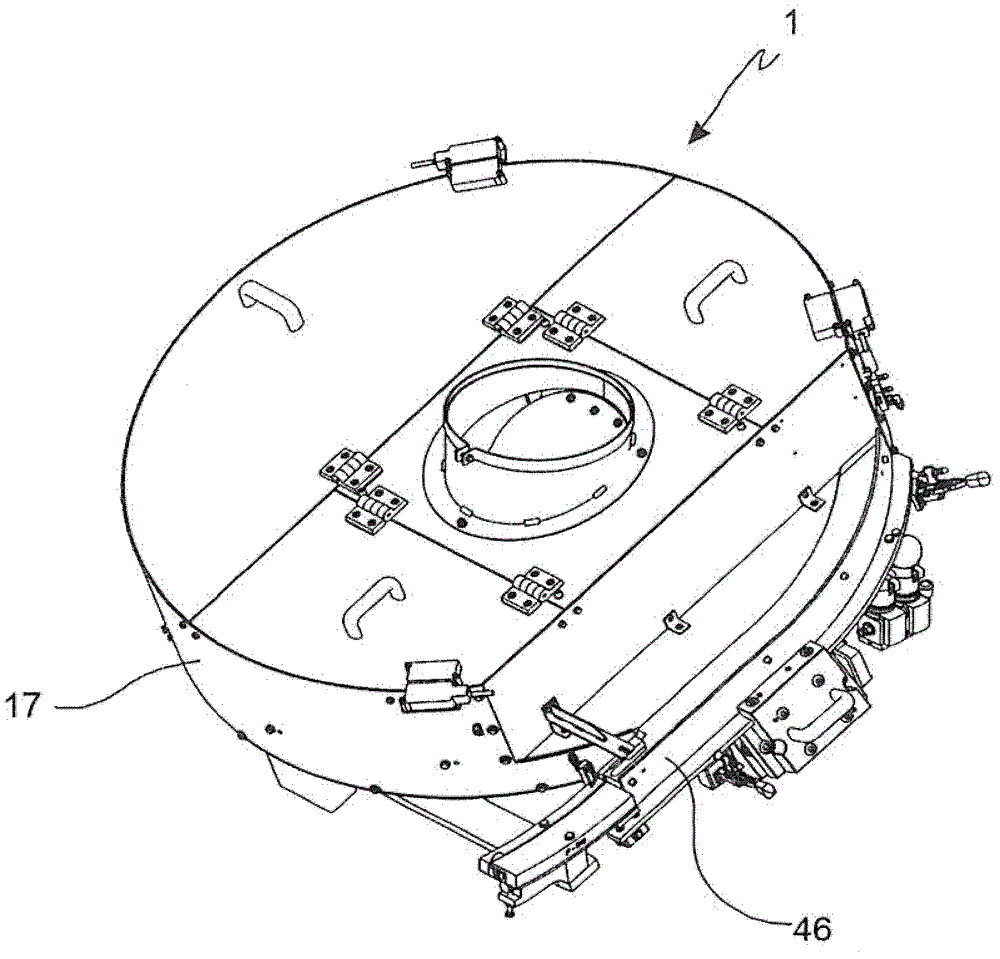

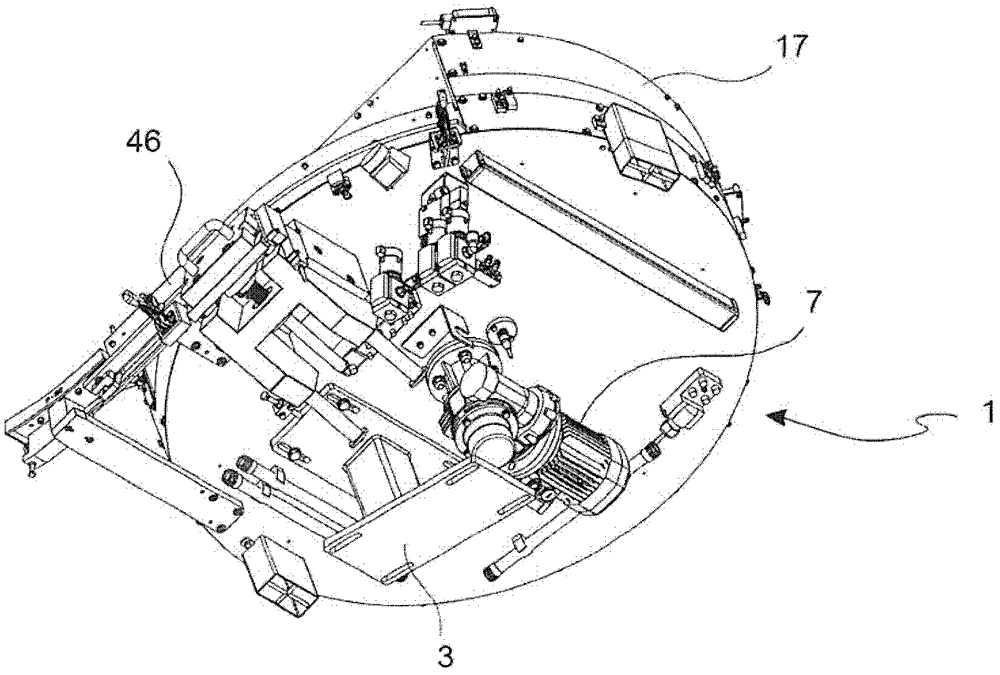

[0037] According to the accompanying drawings, an orientation device 1 for orienting an object 2 comprises: a support structure 3; a series of orientation seats 4, wherein each individual orientation seat 4 is suitable for receiving an individual object 2; A support structure 3 is connected and carries said series of orientation seats 4 , wherein said mounts 5 define a processing path 6 of the object 2 ; and means for moving the series of orientation seats 4 in a direction of movement 8 along the processing path 6 . Referring to the direction of movement 8 , the processing path 6 is delimited upstream by a feed point or section 9 of the objects 2 and downstream by a removal point 10 of the objects 2 and comprising an orientation section 11 arranged downstream of the feed point 9 .

[0038] The orientation device 1 also includes: an orientation member 26 arranged along the orientation portion 11, which is configured to allow objects with an unexpected direction to eject from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com