Preparation method and application of bimetallic photocatalytic functional POM/MOFs

A metal catalyzed light and functional technology, applied in the field of photocatalytic materials, which can solve the problems of large amount of substrate, low catalytic yield, and unrecyclable catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

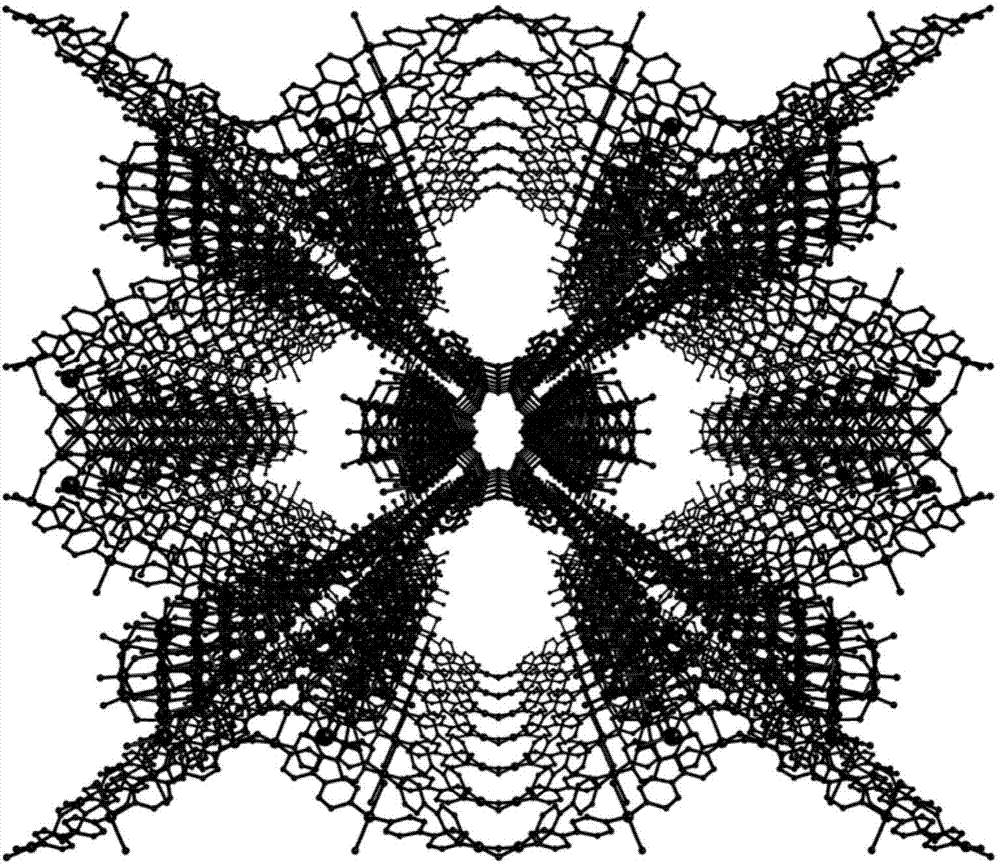

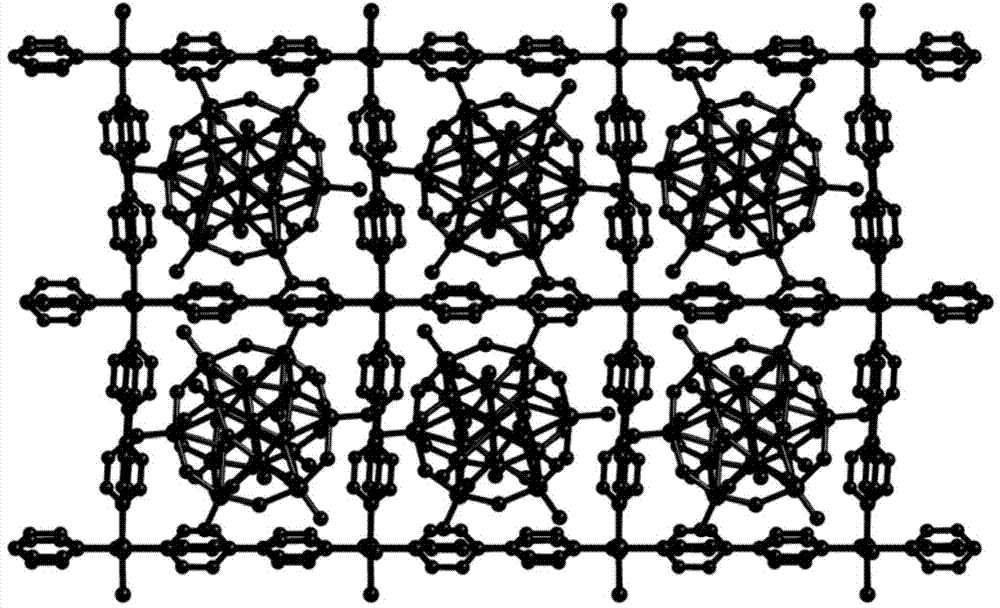

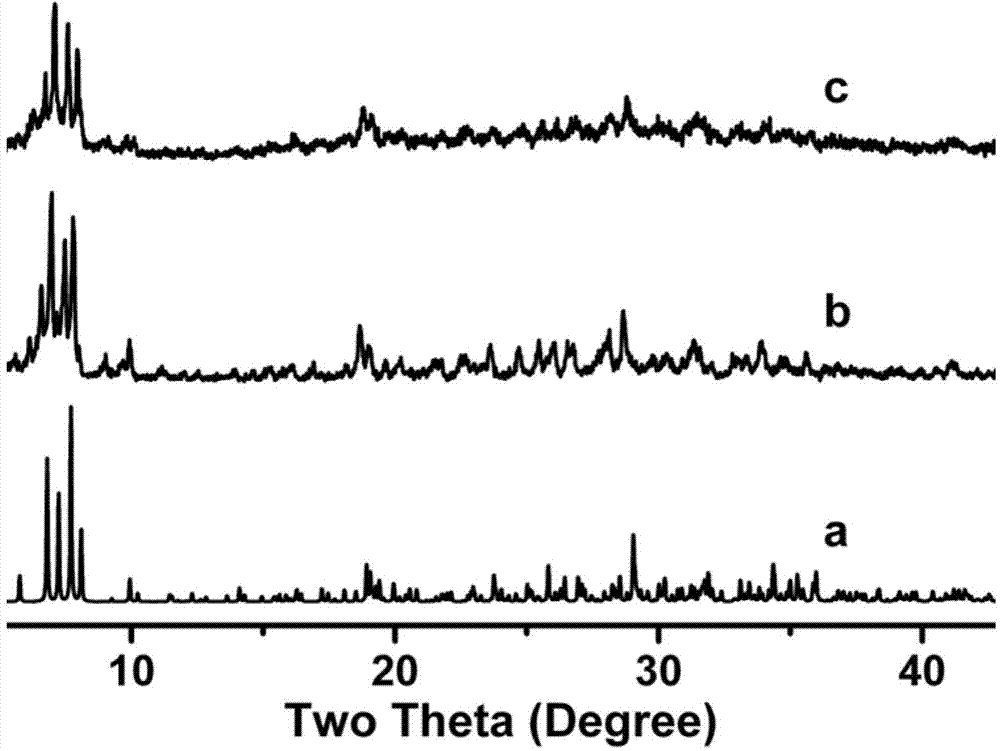

[0034] Will K 5 [SiW 11 o 39 Ru(H 2 O)]·10H 2 O (70.0mg, 0.02mmol), Cu(NO 3 ) 2 ·3H 2 O (30.4mg, 0.12mmol) and 4,4′-bipyridine (19.3mg, 0.12mmol) were dissolved in a mixed solution of water (5.0mL) and acetonitrile (3.0mL), and mixed with 1mol·L –1 HAc adjusted the pH value of the solution to 4.4. After stirring for 12 hours, the above mixed solution was placed in an oven at 120°C. After reacting for 80 hours, it was cooled to room temperature, and brown-black columnar crystals were produced. After washing and drying, the target material POM / MOFs was obtained. (Catalyst Cu-BPY1), the yield is about 52%.

Embodiment 2

[0036] Will K 5 [SiW 11 o 39 Ru(H 2 O)]·10H 2 O (70.0mg, 0.02mmol) and Cu(NO 3 ) 2 ·3H 2 O (9.1 mg, 0.04 mmol) was dissolved in water (5.0 mL) to obtain a lower layer solution, 4,4′-bipyridine (12.5 mg, 0.08 mmol) was dissolved in acetonitrile (5.0 mL) to obtain an upper layer solution, and the middle layer was The mixed solution of acetonitrile and water (1:1, 10.0mL) was slowly added to the test tube (20mL) by layered diffusion method. , brown-black massive crystals were produced, washed and dried to obtain the target material POM / MOFs (catalyst Cu–BPY2), with a yield of about 59%.

Embodiment 3

[0038] Will K 5 [SiW 11 o 39 Ru(H 2 O)]·10H 2 O (70.0mg, 0.02mmol) and CoCl 2 ·6H 2 O (9.5 mg, 0.04 mmol) was dissolved in water (5.0 mL) to obtain a lower layer solution, 4,4′-bipyridine (12.5 mg, 0.08 mmol) was dissolved in acetonitrile (5.0 mL) to obtain an upper layer solution, and the middle layer was The mixed solution of acetonitrile and water (1:1, 10.0mL) was slowly added to the test tube (20mL) by layered diffusion method. , brown-black massive crystals were produced, washed and dried to obtain the target material POM / MOFs (catalyst Co-BPY1), with a yield of about 53%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com