Anti-reversal device of rear roller drive in spinning frame

A spinning frame, anti-reverse technology, used in spinning frames, continuous winding spinning frames, textiles and papermaking, etc., can solve the problems of yarn breakage, yarn thickness and detail, negligence, etc., and achieve smooth operation. Reliable, compact results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

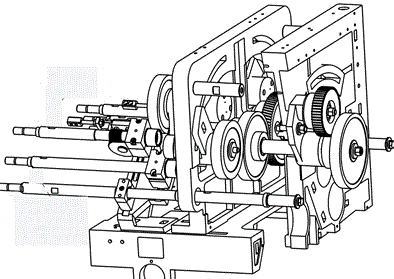

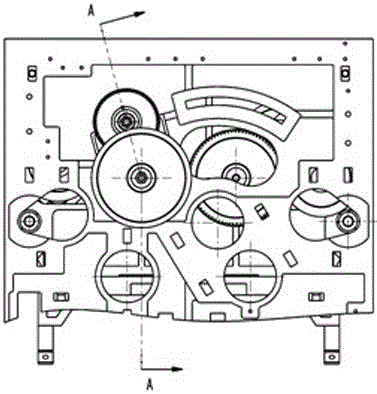

Image

Examples

Embodiment Construction

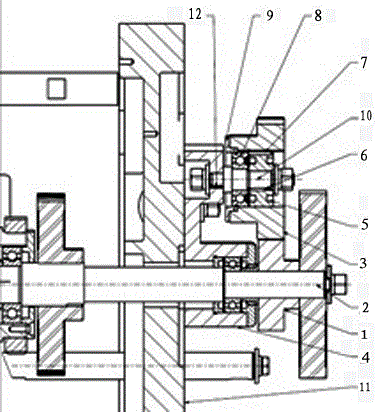

[0018] like image 3 As shown, the anti-reversal device of the back roller transmission in the spinning frame includes the first gear 1, the middle and back roller transmission shaft 2, the stop gear 3, the double-hole bearing seat 4, the overrunning clutch 5, the first key 6, the stop Device 7, bearing 8, end cover 9, anti-rotation shaft 10, drafting wallboard 11, second key 12, double-hole bearing seat 4 is fixed on the drafting wallboard 11 of the spinning frame, and the first gear 1 is fixed on the middle rear On the roller transmission shaft 2, the upper shaft hole of the double-hole bearing seat 4 is provided with a keyway, which is fixedly connected with the anti-rotation shaft 10 through the second key 12, and the other end of the anti-rotation shaft 10 is provided with a bearing 8 and an overrunning clutch 5, through the stop nut The bearing 8 and the overrunning clutch 5 are fixed on the anti-rotation shaft 10, the stop gear 3 is arranged on the outer ring of the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com