Connector housing of connector

A technology of connectors and housings, applied in the field of connector housings, which can solve the problems of inconvenient use, inconvenient installation and removal of dust-proof covers, and easy loss of dust-proof covers, etc., and achieves the effect of quick and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

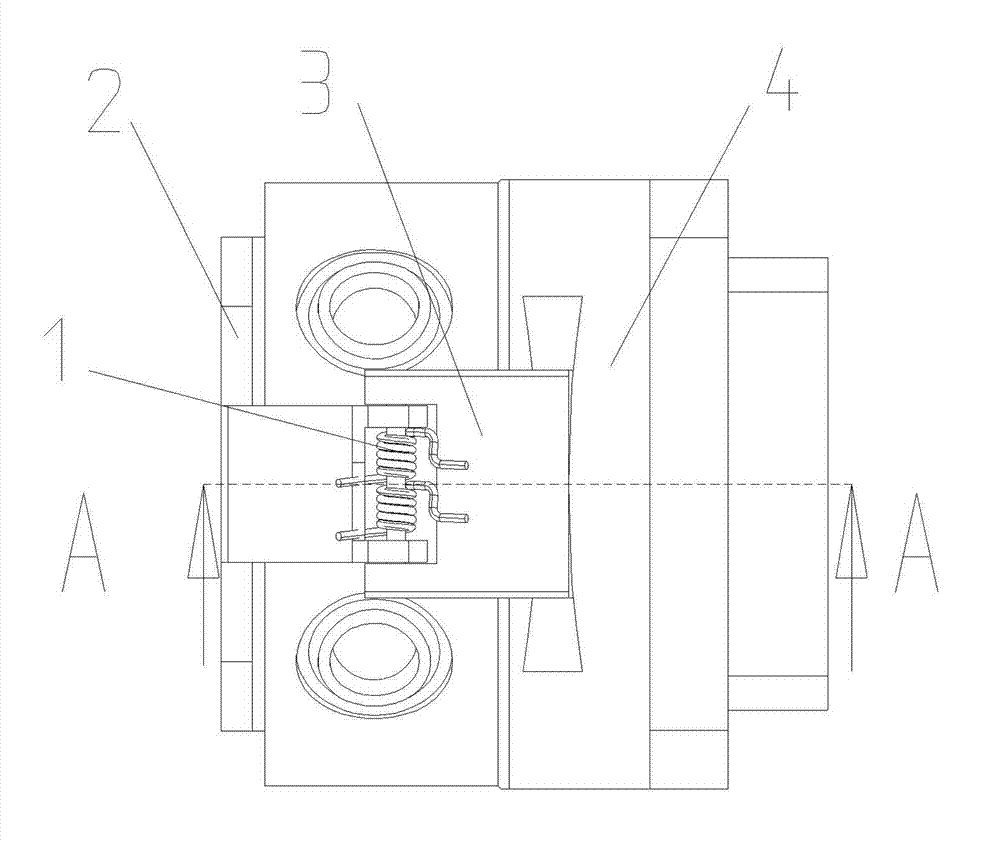

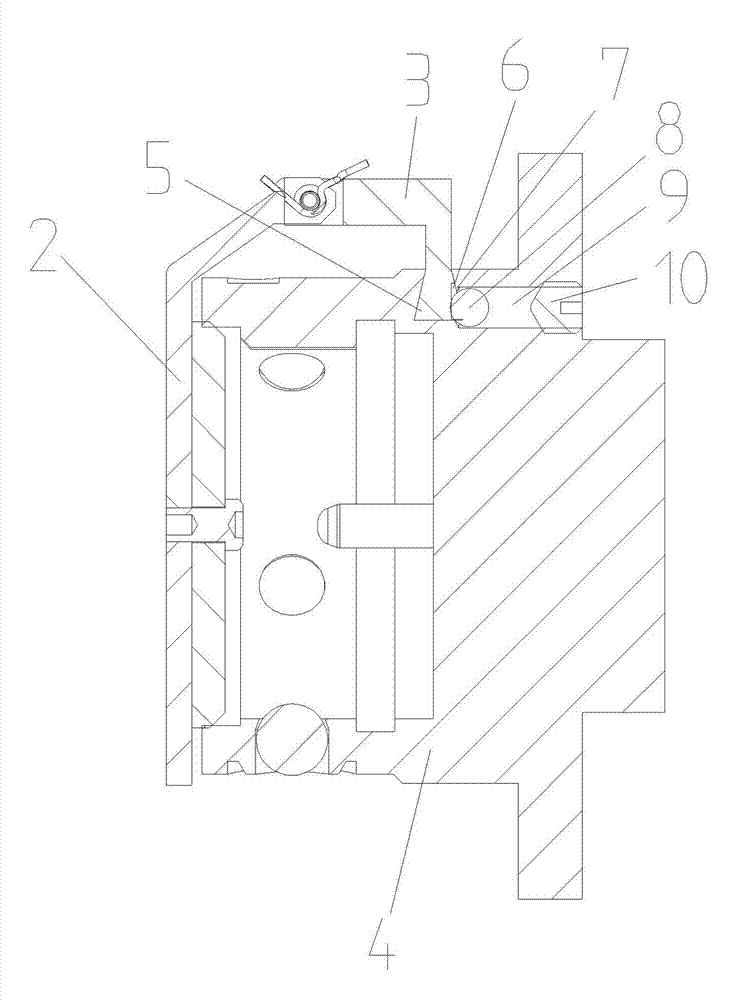

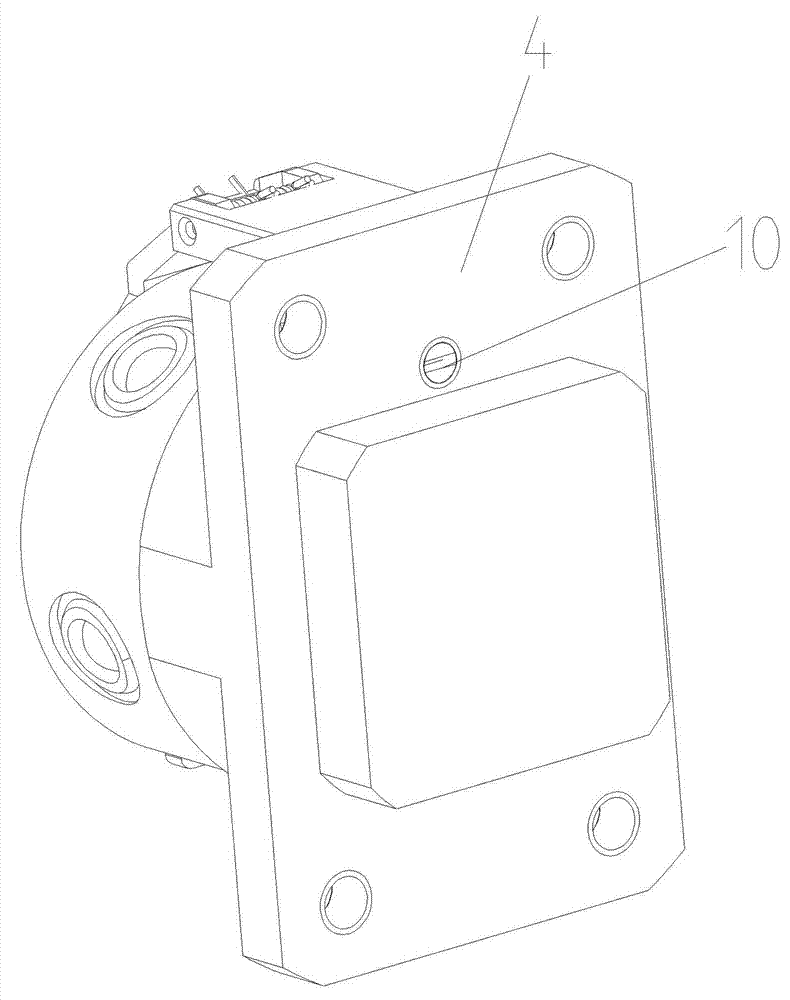

[0018] The connector includes a dust cover 2 and a connector housing 4, the structure of the dust cover is as follows Image 6 As shown: the dust cover includes a dust cover seat 3 provided with a linear installation guide rail 5 and a cover plate 2 hinged on the dust cover seat 3 through a hinge shaft for sealing the front end of the connector housing. On the cross-section of the extension direction of the installation guide rail, the cross-sectional shape of the linear installation guide rail 5 is a dovetail shape with a large bottom and a small top. The extension direction of the hinge axis of the plate is consistent with the extension direction of the linear installation guide rail, and a return torsion spring 1 is arranged between the cover plate 2 and the dustproof cover seat 4 .

[0019] Examples of connector housings are Figure 1~5 As shown: the connector housing 4 includes a body whose front end is a plug-in end. The outer peripheral surface of the body is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com