Trivalent chromium-conversion processing solution containing aluminum-modified colloidal silica

一种胶态氧化硅、转化处理的技术,应用在氧化硅、二氧化硅、防腐涂料等方向,能够解决不利影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

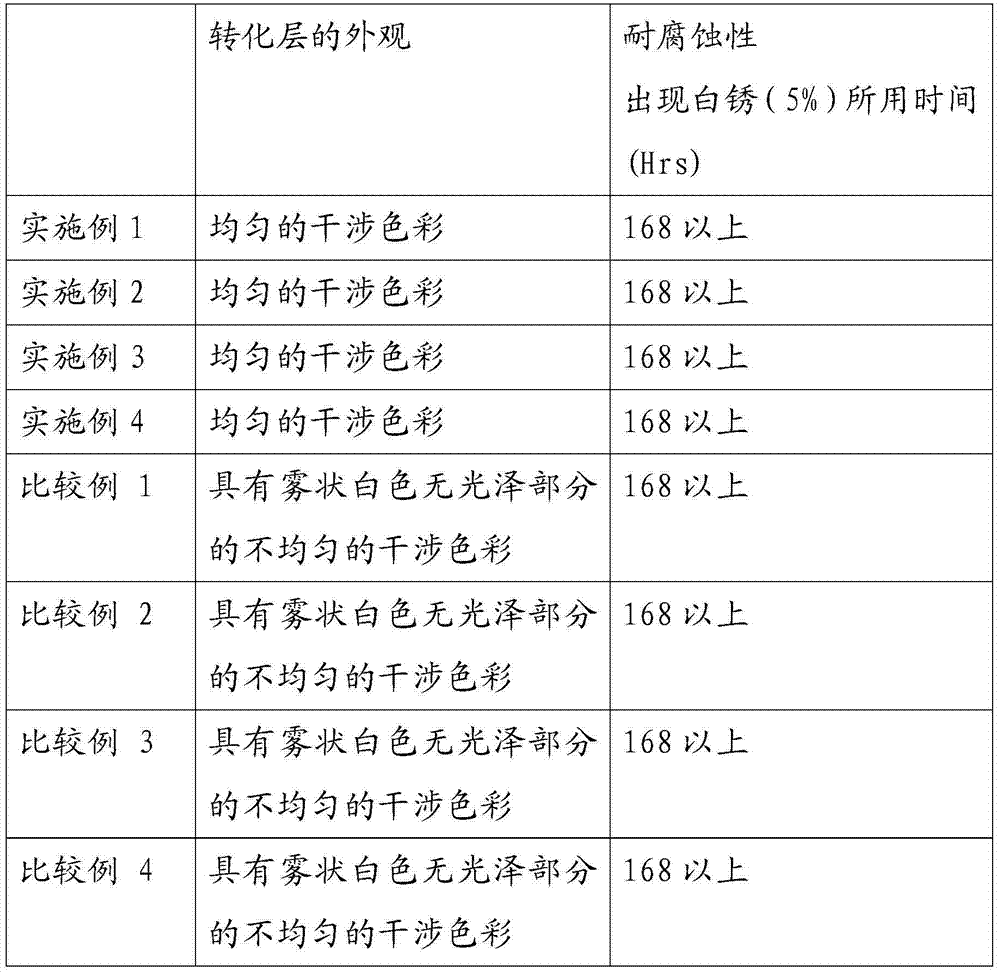

Examples

Embodiment 1

[0023]The bolts obtained by zincate Zn plating with a thickness of 8 μm obtained by using the NZ-100 plating solution produced by Deepsol Co., Ltd. were immersed in the following trivalent chromium conversion treatment solution (put the bolts into a basket made of stainless steel stirring in). The treatment temperature was 35° C., and the treatment time was 40 seconds.

[0024] A trivalent chromium conversion treatment liquid was prepared by adding LUDOX AM produced by DuPont of the United States as colloidal silica in an amount of 30 g / L to 70 mL / L of ZT-444CS produced by Deepsol Co., Ltd. The pH of the treatment solution was adjusted to pH 2.7 with NaOH.

Embodiment 2

[0026] The bolts obtained by zincate Zn plating with a thickness of 8 μm obtained by using the NZ-110 plating solution produced by Deepsol Co., Ltd. were immersed in the following trivalent chromium conversion treatment solution (put the bolts into a basket made of stainless steel stirring in). The treatment temperature was 30° C., and the treatment time was 25 seconds.

[0027] Preparation of trivalent chromium conversion treatment by adding SNOWTEX CXS produced by Nissan Chemical Industries Co., Ltd. as colloidal silica to 100 mL / L of ZT-444A produced by Deepsol Co., Ltd. liquid. The pH of the treatment solution was adjusted to pH 3.0 with NaOH.

Embodiment 3

[0029] Immerse the bolts obtained by using the NZ-200 plating solution produced by Deepsol Co., Ltd. to obtain a zincate Zn coating with a thickness of 8 μm in the following trivalent chromium conversion treatment solution (put the bolts into a basket made of stainless steel stirring in). The treatment temperature was 30° C., and the treatment time was 40 seconds.

[0030] Trivalent chromium conversion treatment was prepared by adding SILICADOL 20AL produced by Nippon Chemical Industry Co., Ltd. as colloidal silica to 75 mL / L of ZT-444DSM1 produced by Deepsol Co., Ltd. liquid. The pH of the treatment solution was adjusted to pH 2.5 with NaOH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com