Number plate paint wiping machine and method

A technology for license plates and paints, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., can solve problems such as low work efficiency, and achieve the effect of fast and efficient wiping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

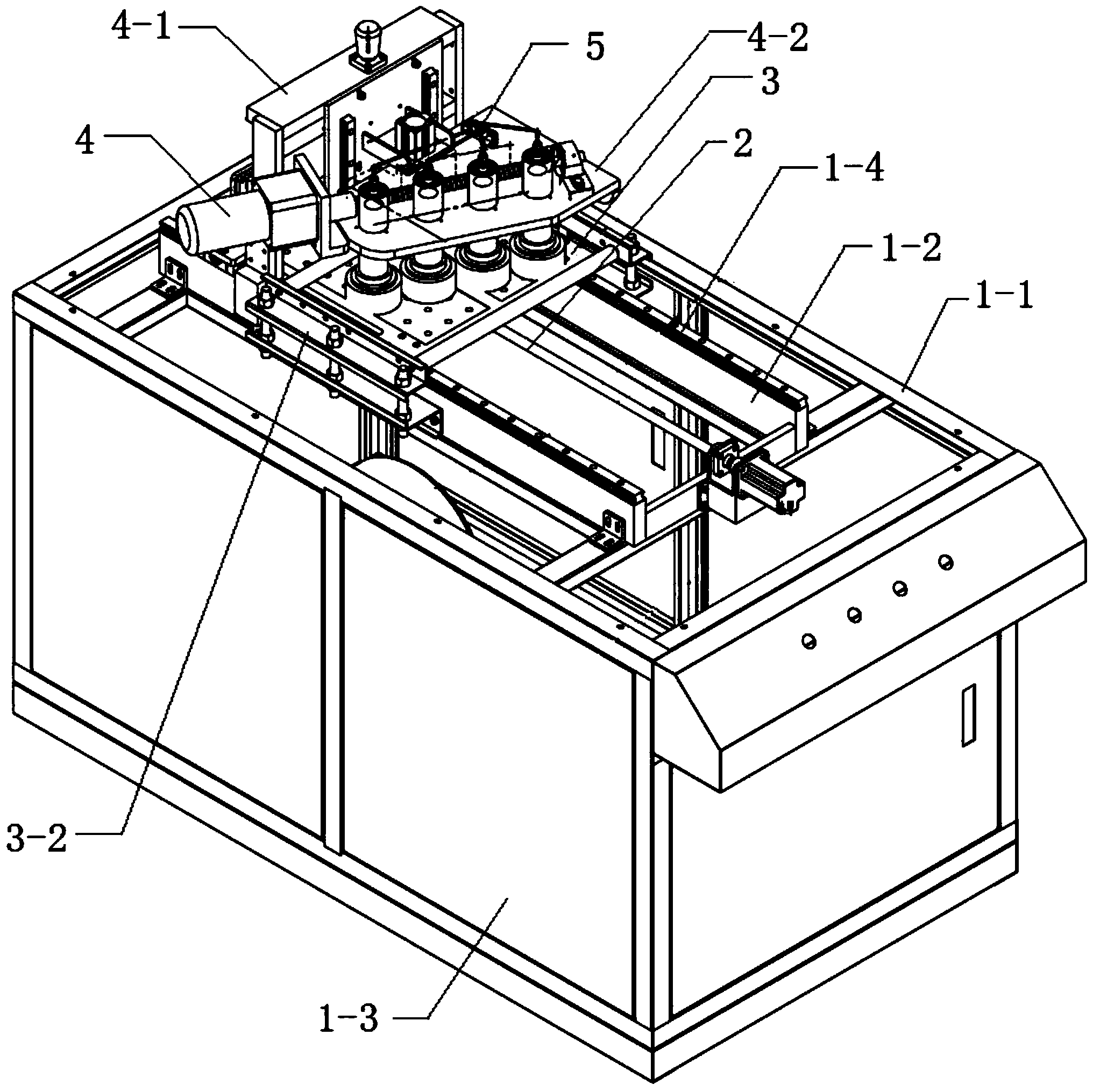

[0038] Embodiment 1: a kind of license plate paint wiping machine, its structure is as Figure 1-5 Shown: includes:

[0039] A frame 1-1, a support frame 1-2 is installed on the frame 1-1, slide rails 1-4 are installed at both ends of the support frame 1-2, and a fan 6 is installed in the frame 1-1;

[0040] A reciprocating mechanism 2 arranged on the support frame 1-2;

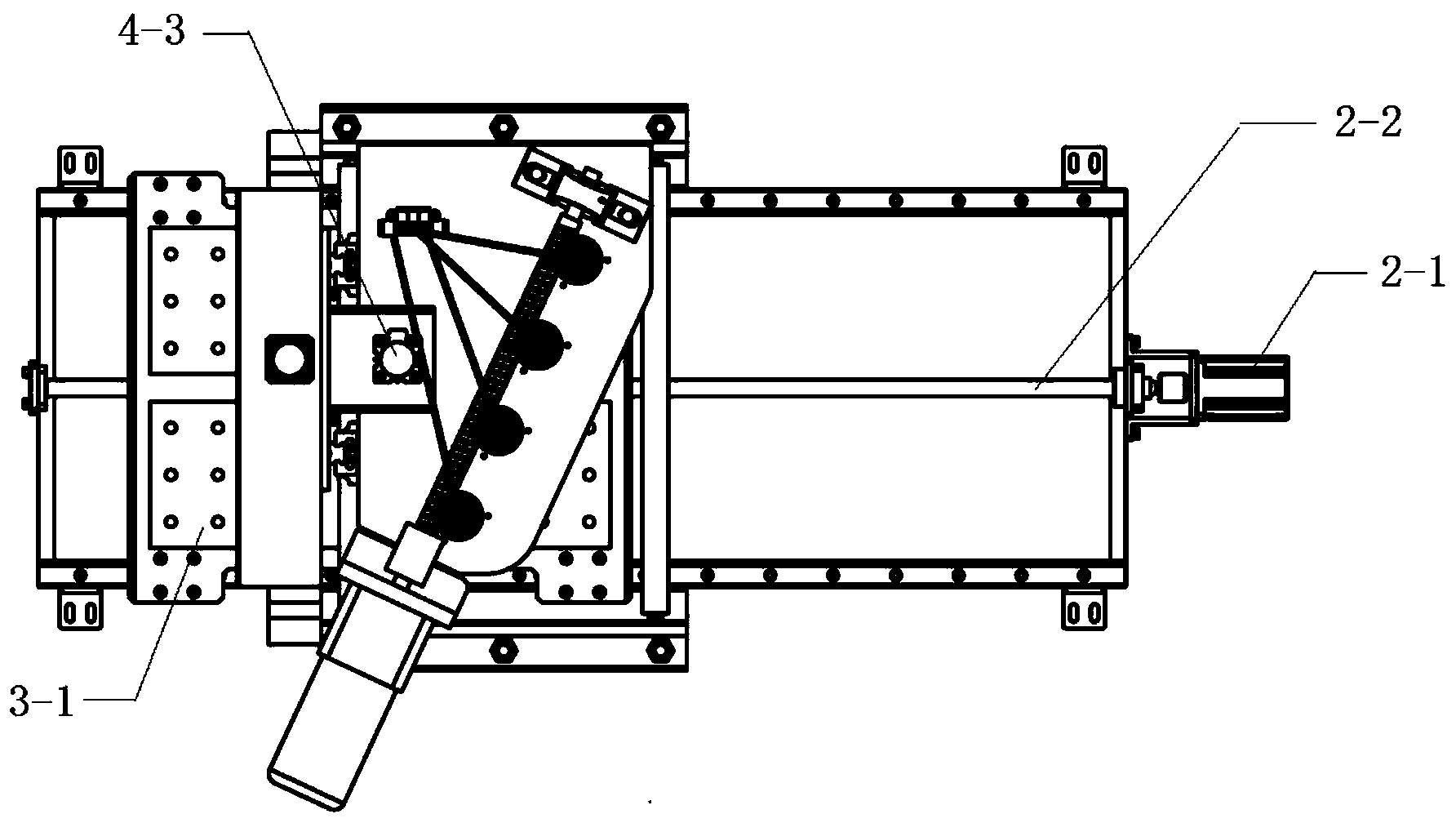

[0041] A license plate positioning mechanism 3 connected to the reciprocating mechanism 2;

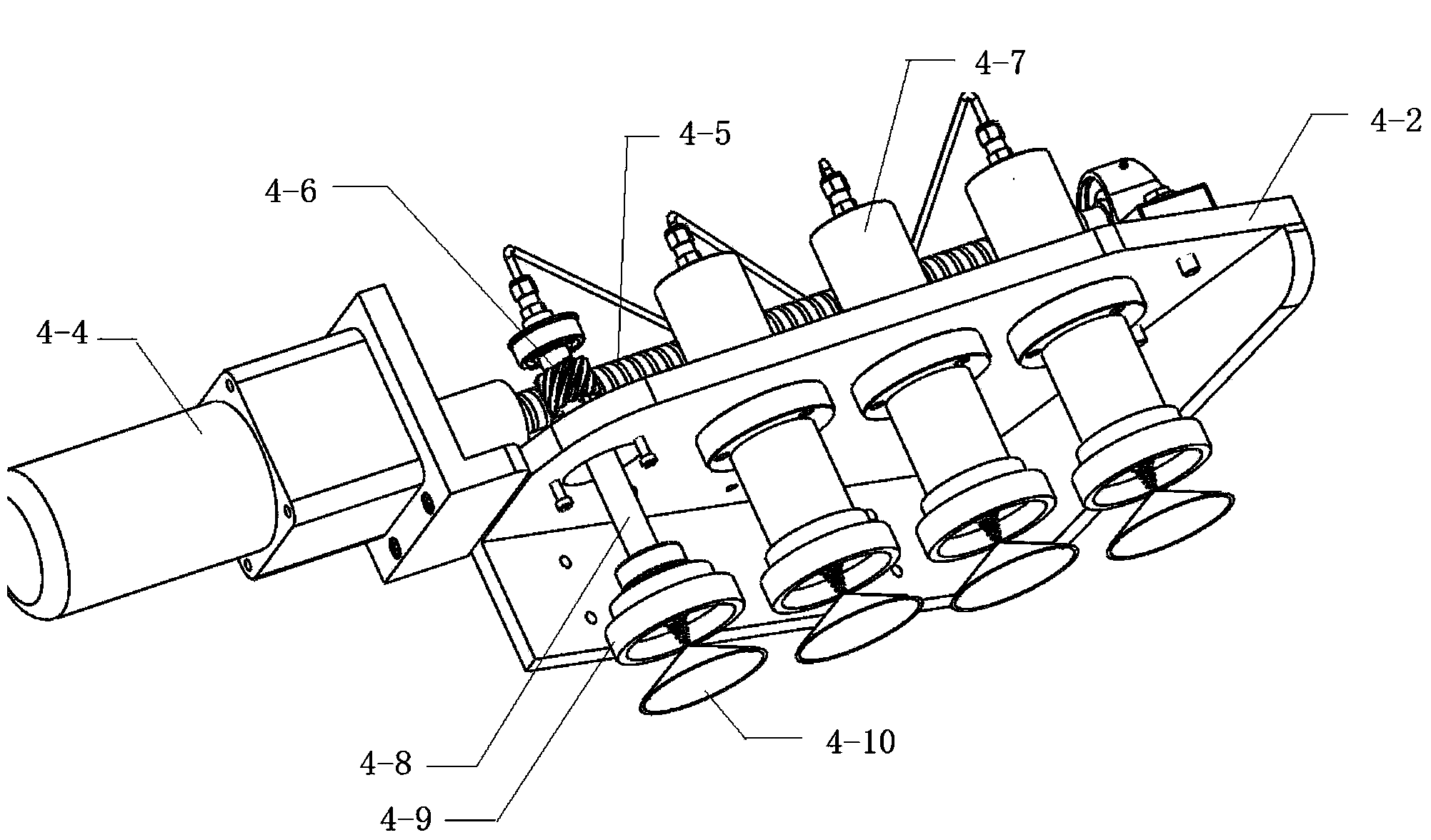

[0042] The wiping mechanism 4 fixedly connected with the frame 1-1;

[0043] The spray mechanism 5 installed on the wiping mechanism 4;

[0044] Wherein, the license plate positioning mechanism 3 is located below the wiping mechanism 4;

[0045] A sealing plate 1-3 is installed on the side of the frame 1-1;

[0046] Described license plate positioning mechanism 3 comprises positioning box 3-1, and positioning box 3-1 communicates with blower fan 6 through pipeline, and the two ends of positioning box 3-1 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com