Cloth drying device

A cloth drying and hot air technology, applied in drying, drying machine, drying gas arrangement, etc., can solve problems such as waste of energy, damage to cloth tissue, and large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

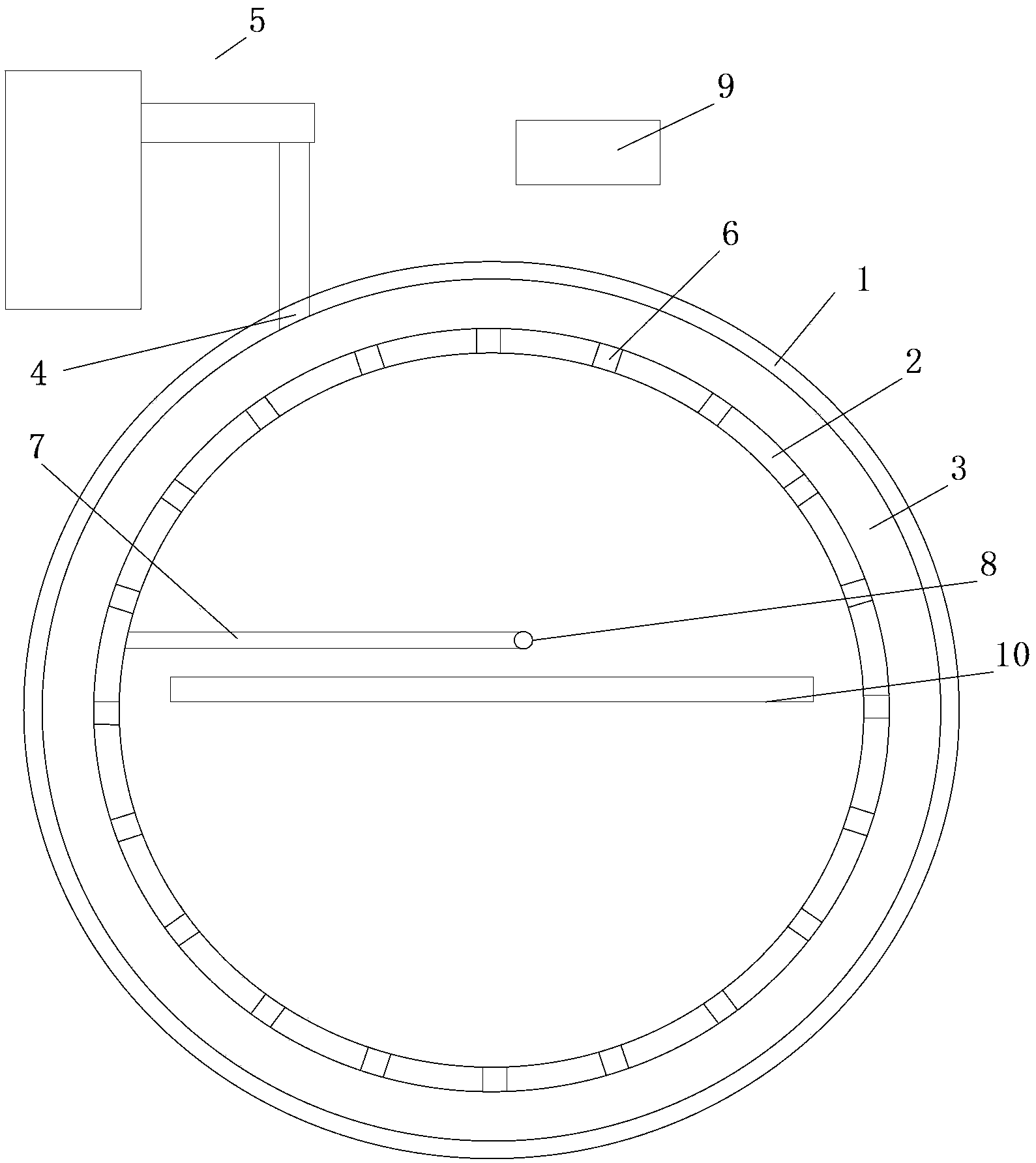

[0012] see figure 1 , a cloth drying device, comprising a first cylinder body 1 and a second cylinder body 2 with a circular cross section, the second cylinder body is located in the first cylinder body, and a closed cylinder is formed between the inner wall of the first cylinder body and the outer wall of the second cylinder body The hot gas interlayer 3 is provided with a heat-sending through hole 4 communicating with the hot gas interlayer on the first cylinder; the heat-sending through hole is communicated with the external hot gas delivery device 5; the second cylinder is provided with several communicating hot gas interlayers and The hot gas passage hole 6 in the inner cavity of the second cylinder. The circular through hole of the hot gas through hole has a diameter of 1mm, 2mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm; The support 7 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com