Annular vapor chamber structure and its manufacturing method

A vapor chamber and ring-shaped technology, which is applied in the field of ring-type vapor chamber structure and its manufacturing method, can solve problems such as unfavorable, unfavorable assembly, and inability to effectively maintain the surface flatness of the plate body, and achieve the best heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

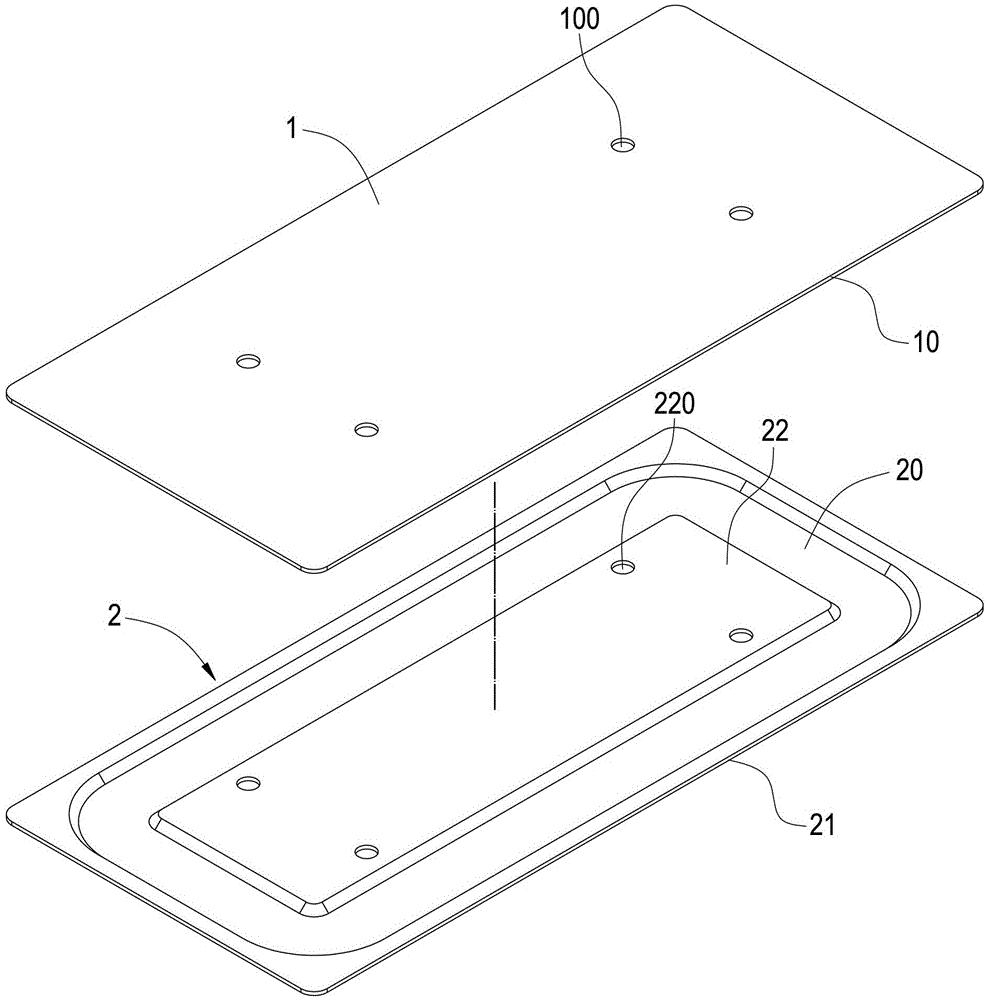

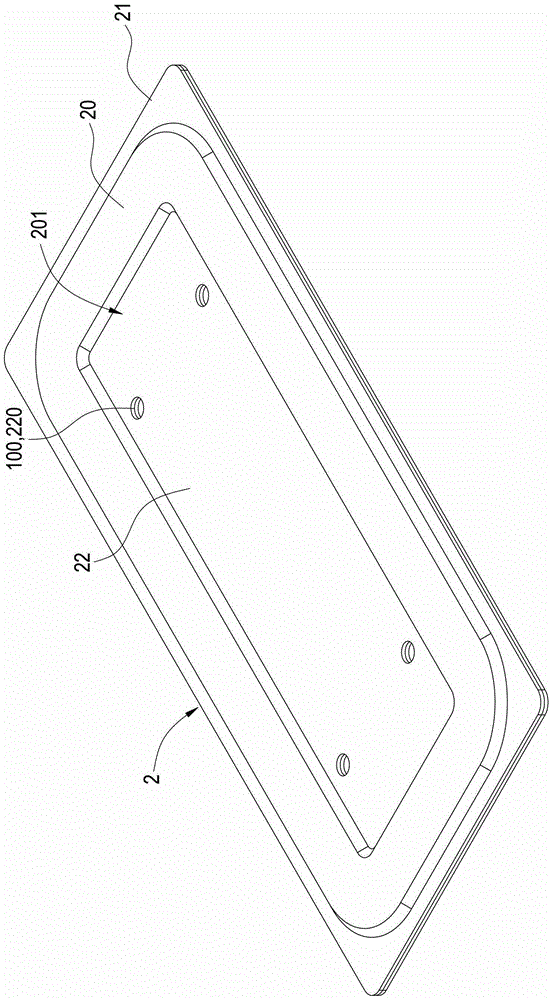

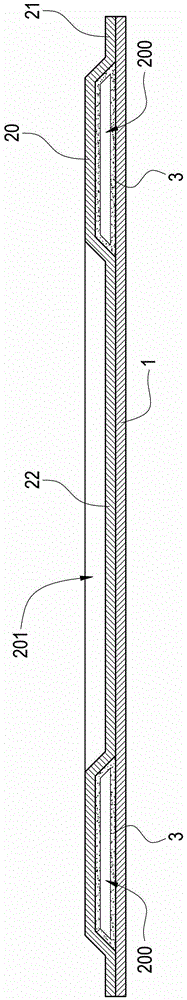

[0042] In order to enable your examiner to further understand the characteristics and technical content of the present invention, please refer to the following detailed description and drawings of the present invention. However, the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

[0043] see figure 1 , figure 2 and image 3 , respectively are the perspective exploded schematic diagram of the first embodiment of the present invention, the perspective combination diagram of another perspective, and the combination cross-sectional diagram of another perspective. The present invention provides a ring-type vapor chamber structure and its manufacturing method. The ring-type vapor chamber structure includes a flat plate 1 and a cover plate 2 that covers the flat plate 1; wherein:

[0044] The flat plate 1 has an inner surface 10 , and the inner surface 10 is attached to one side of the cover plate 2 . Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com