Perfume glass bottle processing apparatus

A processing device and glass bottle technology, applied in glass molding, glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of complex production methods, low production efficiency, unfavorable industrial production, etc., and achieve the firmness of perfume glass bottles and eliminate internal stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

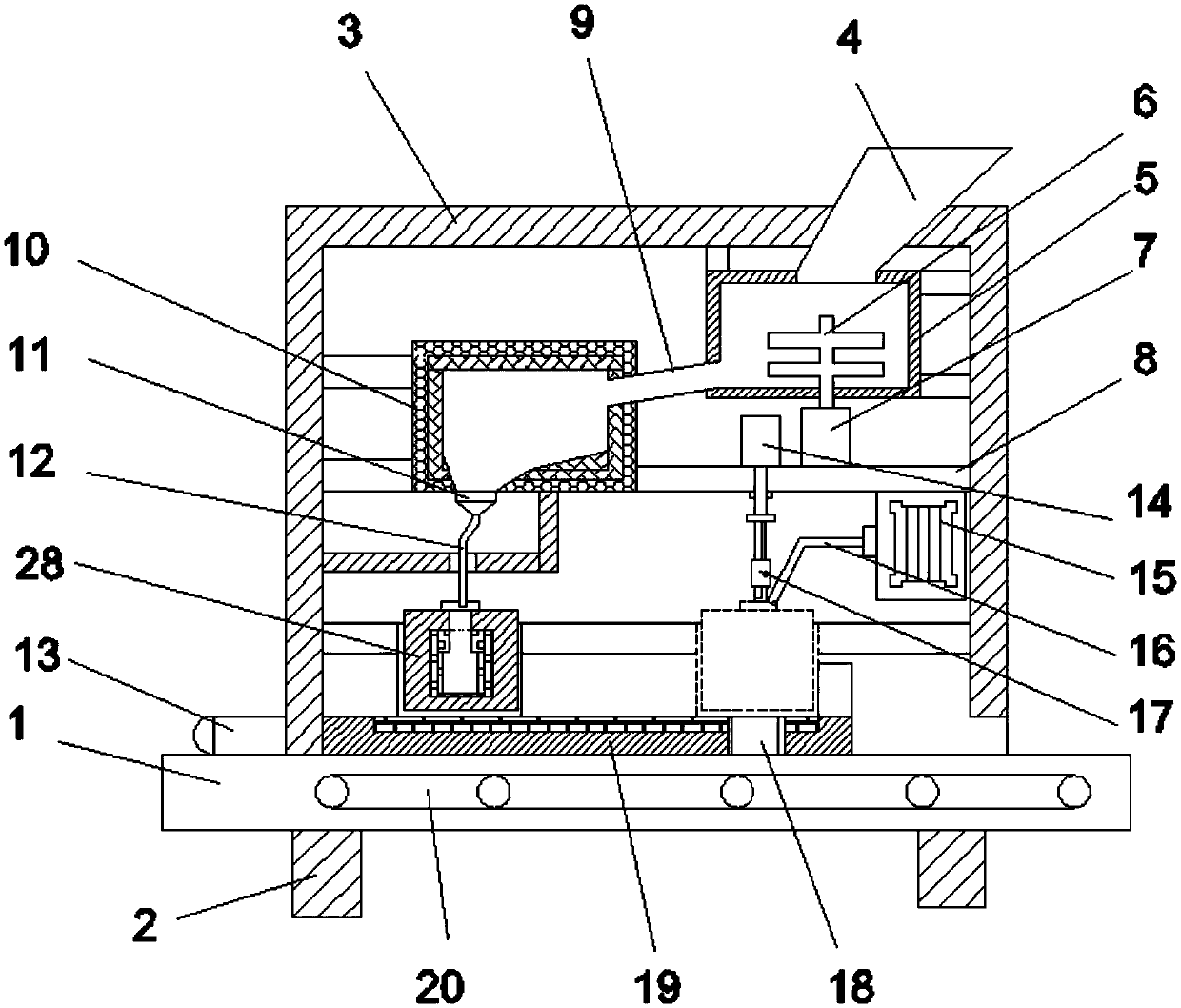

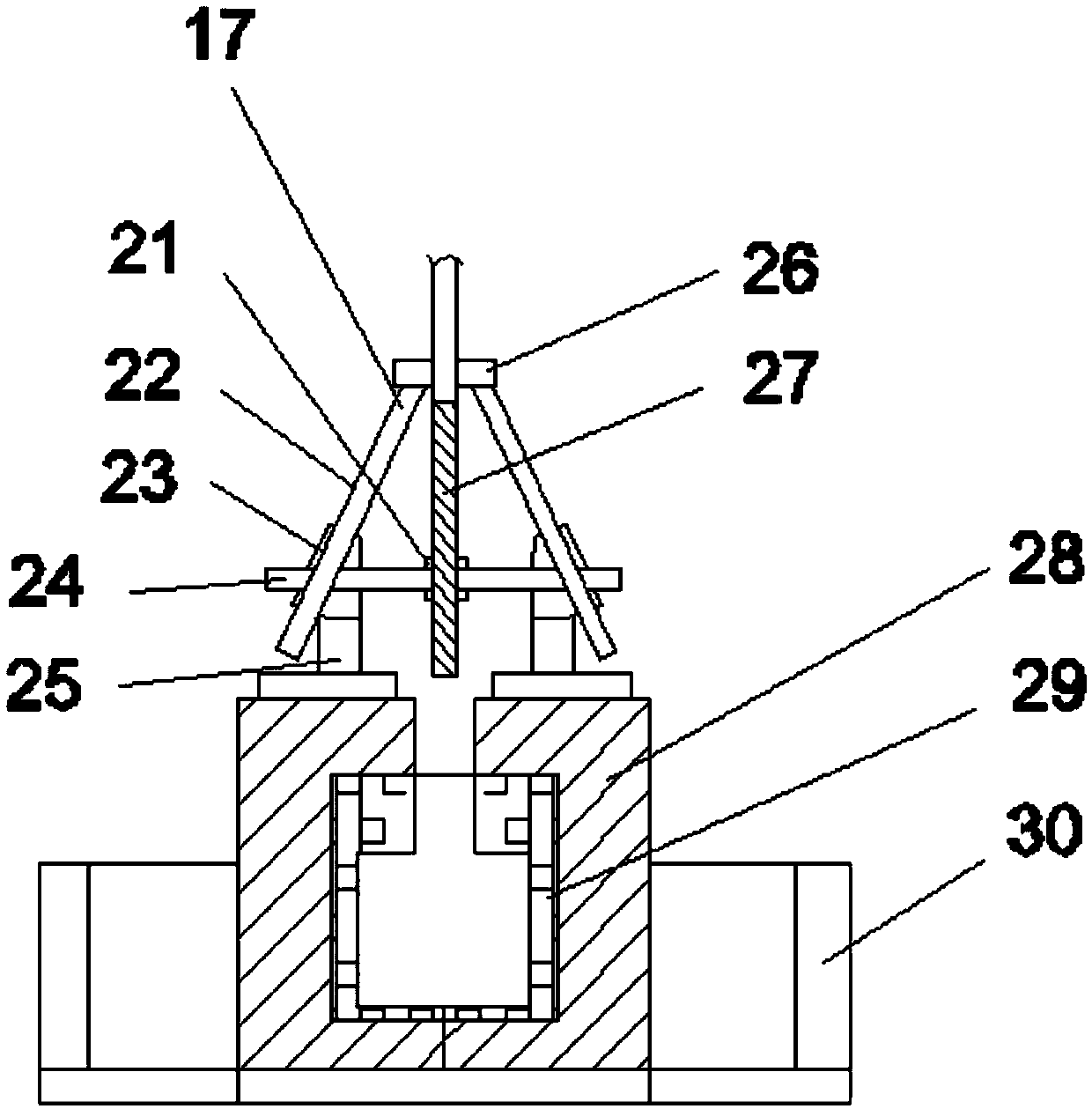

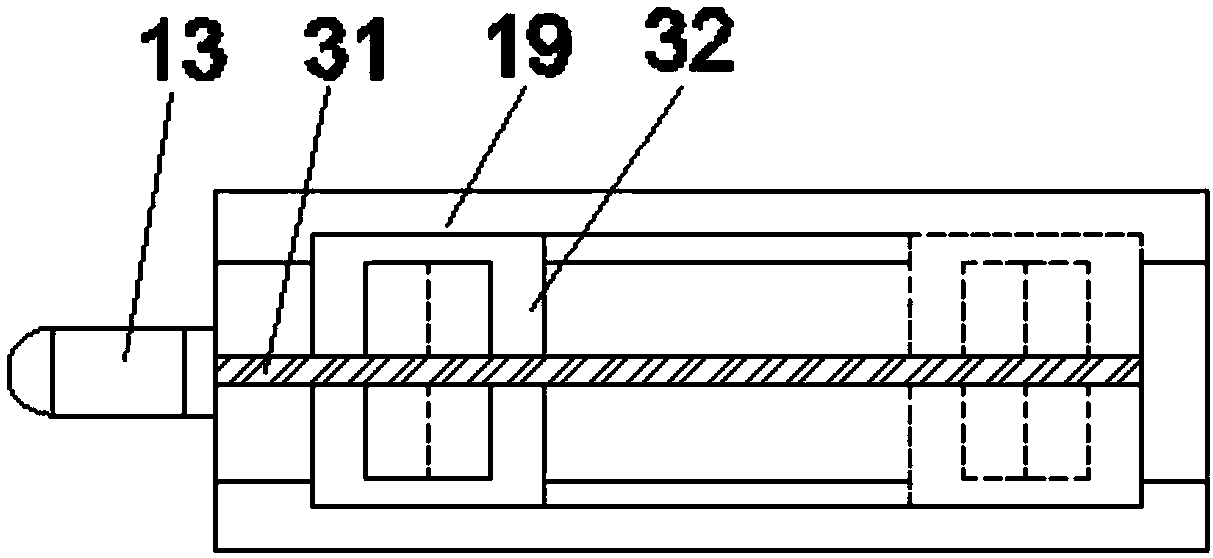

[0020] Such as Figure 1-Figure 3 As shown, a glass bottle processing device for perfume proposed by the present invention includes a mounting frame 1, an equipment fixing frame 3, a mixing chamber 5 and a demoulding device 17, the lower end of the mounting frame 1 is provided with a support frame 2, and the upper end of the mounting frame 1 is provided with There is an equipment fixing frame 3, a conveyor belt 20 is arranged on the mounting frame 1, an equipment feeding port 4 is arranged on the right side of the upper end of the equipment fixing frame 3, the lower end of the equipment feeding port 4 communicates with the upper end of the mixing chamber 5, and the middle part of the inner bottom of the mixing chamber 5 A stirring shaft 6 is provided, and the lower end of the stirring shaft 6 runs through the wall of the stirring chamber 5 and is provided with a first motor 7. The upper part of the equipment fixing frame 3 is provided with a horizontal plate 8, and the left end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com