Axial movement device for welding of bus tube

A technology of axial movement and bus pipe, applied in the direction of welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problem of butt welding being limited to indoors, and achieve the effect of good automation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

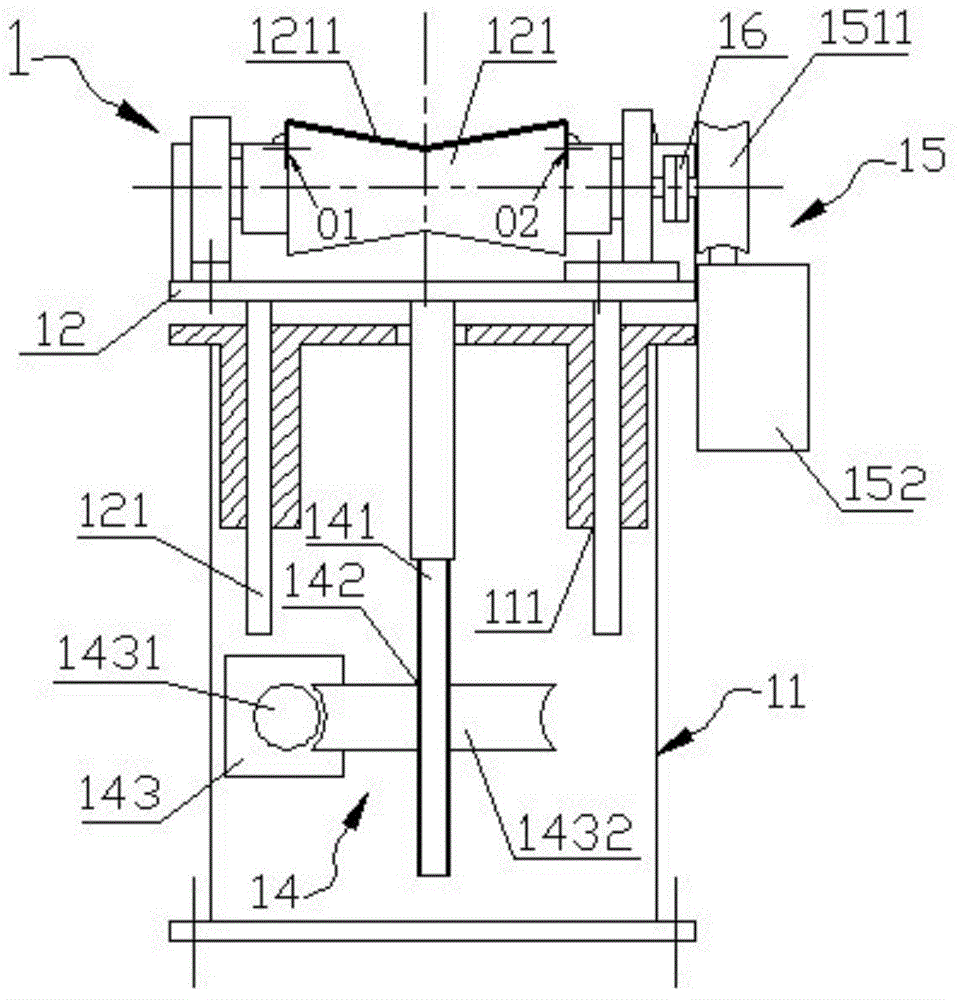

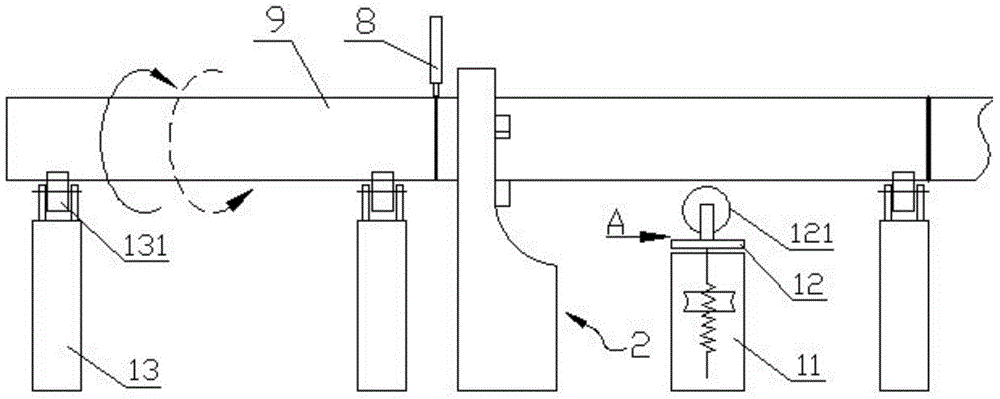

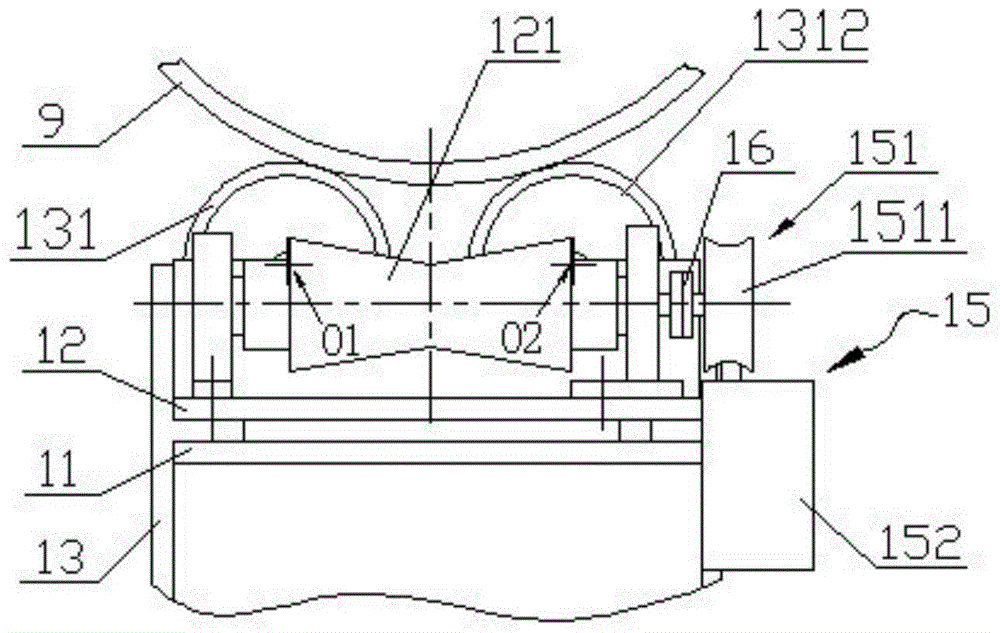

[0019] Such as figure 1 , The bracket device of this embodiment has a main bracket 11 in the shape of a substantially rectangular box, and other components in the bracket device use the main bracket 11 as the main body for installation and connection.

[0020] The rotating roller bracket 12 is placed on the upper end surface of the above-mentioned main bracket 11, and the upper end surface of this side is provided with two guide holes 111, and two guide rods 121 are arranged at the corresponding positions of the lower end of the rotating roller bracket 12, and the two guide rods 121 are respectively inserted into Connected to the corresponding guide hole 111 , the rotating roller bracket 12 is connected to the main bracket 11 by sliding up and down.

[0021] At the same time, the lower end of the rotating roller bracket 12 is connected with a lifter hook 14 , and the lifter hook 14 includes a screw mandrel 141 , a nut 142 , a motor 144 and a worm gear unit 143 . The worm gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com