Pipeline boundary layer damping device

A drag reduction device and boundary layer technology, applied in mechanical equipment, fluid flow, etc., can solve the problems of being in the experimental or theoretical research stage, the use of drag reducing agents are limited, and the flexible wall method is difficult to achieve, etc., to achieve drag reduction effect. The effect of obvious, simple structure, convenient and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

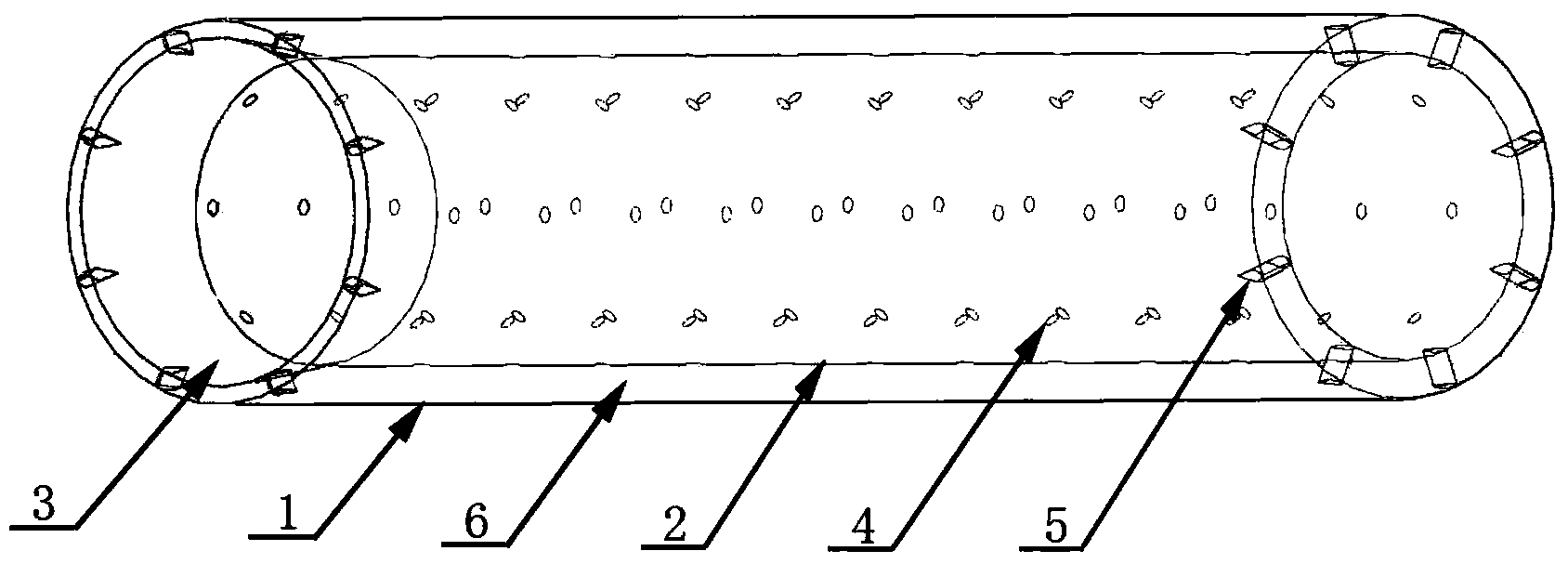

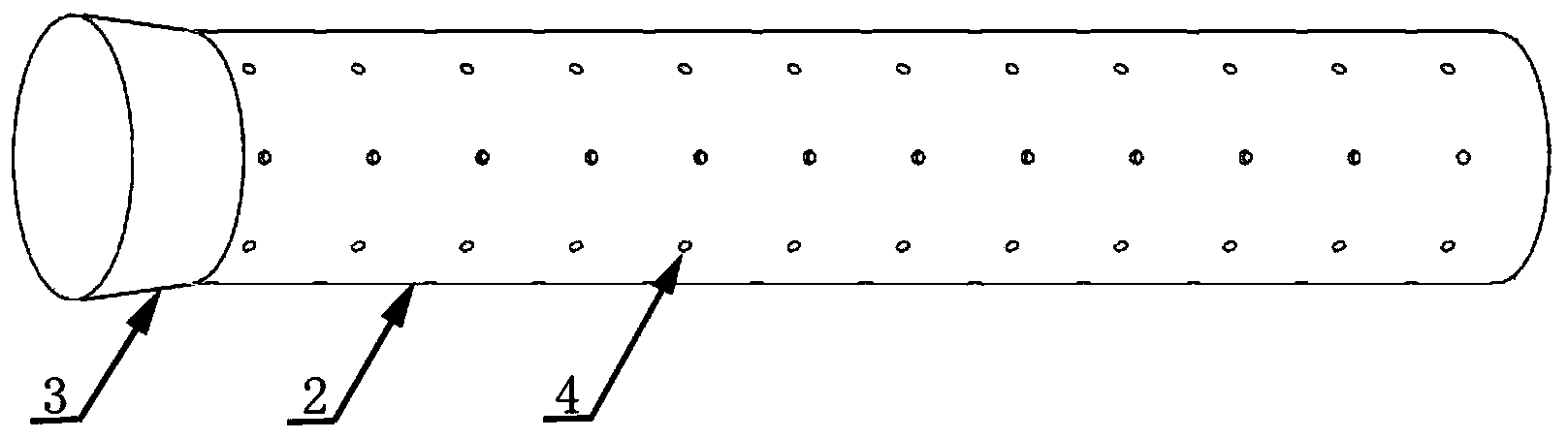

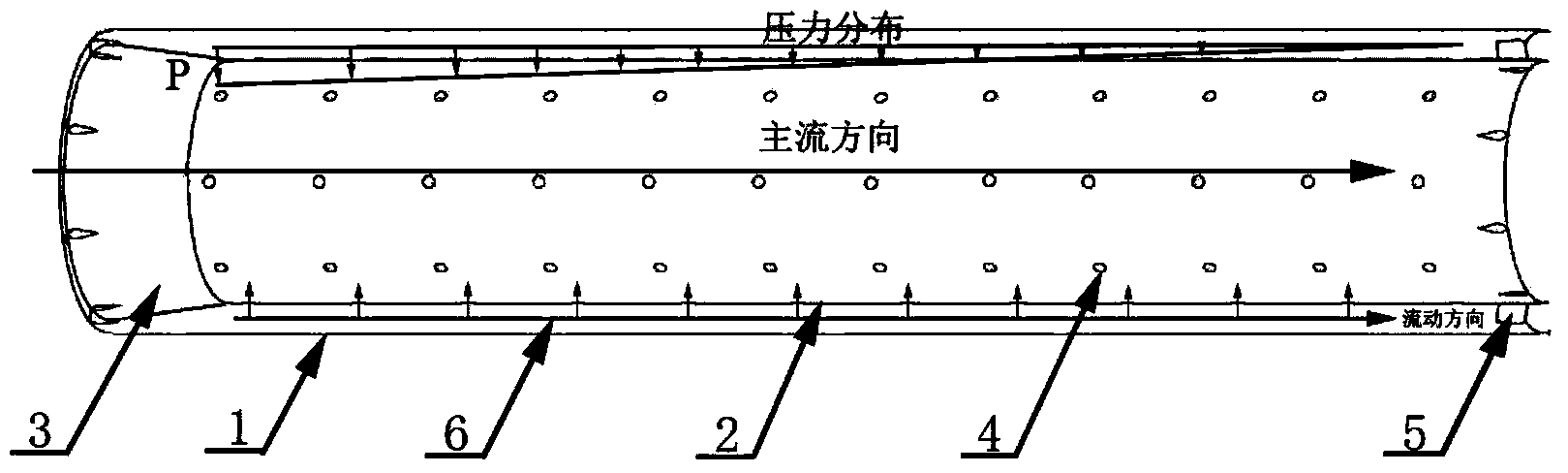

[0015] In order to further understand the drag reducing device for the pipeline boundary layer, the description is as follows with reference to the accompanying drawings.

[0016] It includes an outer tube 1, which is not specially treated, and a thin-walled inner tube 2 is installed inside the outer tube 1, and injection holes 4 are uniformly arranged on the wall of the inner tube 2. The fluid inlet of the inner pipe 1 (the beginning section of the pipeline) is connected with a tapered nozzle 3, the outer diameter of the inner pipe 2 is smaller than the inner diameter of the outer pipe 1, and an interlayer 6 is formed between the inner pipe 2 and the outer pipe 1, and the thickness of the interlayer 6 is determined by the fluid The two ends of the outer tube 1 and the inner tube 2 are respectively connected by a streamlined connecting support plate 5; the connecting support plate 5 is streamlined to reduce the flow resistance entering the interlayer 6; when the fluid flows in,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com