A heat-insulating hanger device for a refrigerant pipe and a method for installing the refrigerant pipe

A technology for refrigerant pipes and hangers, which is applied in the direction of protecting pipes, pipe supports, pipes/pipe joints/fittings through heat insulation, which can solve the problems of high material cost, low installation efficiency, and many insulation gaps, etc., and achieve simplified structure, Improve efficiency and prevent cold bridge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

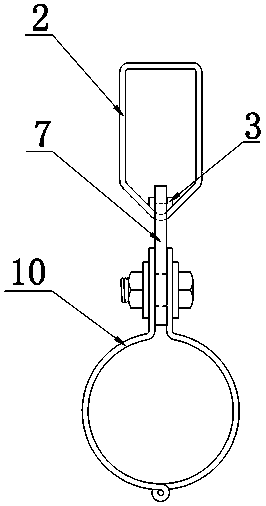

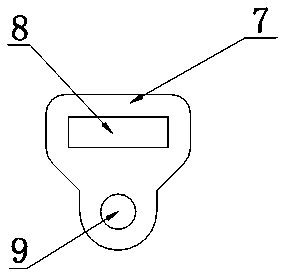

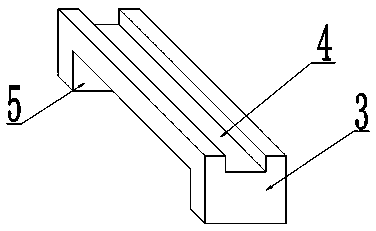

[0040] Such as Figure 1~3 As shown, the present invention is mainly applied to the installation of refrigerant pipes, which includes an elevation adjustment suspension frame 2, a heat insulation saddle 3, a pipe clamp lifting plate 7, and a pipe holding mechanism. Such as figure 2As shown, the pipe clamp lifting plate 7 is respectively provided with a connecting hole 8 and a first threaded hole 9 , wherein the first threaded hole 9 is located below the connecting hole 8 . The connection hole 8 is used for interlocking the elevation adjustment suspension frame 2 and the pipe clamp suspension plate 7 together. The pipe holding mechanism is provided with a second threaded hole and a third threaded hole that are identical in size and shape to the first threaded hole 9, and the pipe holding mechanism is connected by bolts with the first threaded hole and the second threaded hole. Cooperate and connect with pipe clamp hanging plate 7. Specifically, the pipe holding mechanism in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com