Heat insulation hanger applied to air duct belt hanger and method for installing air duct

A technology of pipe belt type and hanger, which is applied in the direction of protecting pipes, pipes/pipe joints/fittings, pipe supports, etc. through heat insulation, which can solve the problems of difficult layout of comprehensive pipelines, poor environmental protection, and size deviation of heat insulation blocks, etc., to achieve Eliminates heat insulation material, strong fatigue resistance, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

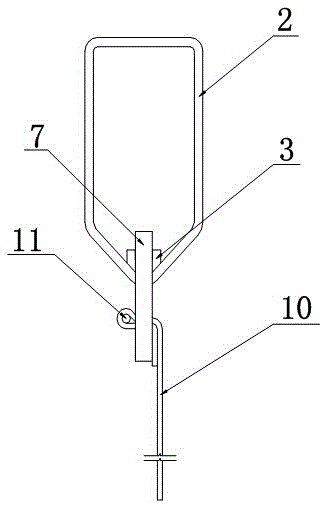

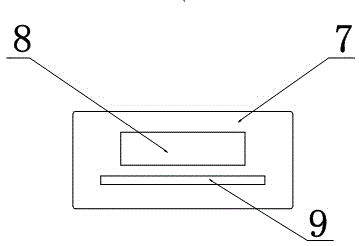

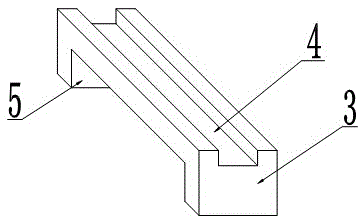

[0043] Such as Figure 1~3 As shown, the present invention is mainly applied to the sling-type air duct, which includes an adjustment frame 2 , a heat-insulating saddle 3 , a hanging plate 7 , a sling 10 and a lock shaft 11 . Such as figure 2 As shown, the hanging plate 7 is respectively provided with a first connecting hole 8 and a second connecting hole 9 , wherein the second connecting hole 9 is located below the first connecting hole 8 . The first connecting hole 8 is used to buckle the adjusting frame 2 and the hanging plate 7 together. One end of the sling 10 passes through the second connecting hole 9 and clings to the outer edge of the lock shaft 11 for a circle, and then passes back to the second connecting hole 9 from the opposite direction, because the length of the lock shaft 11 is greater than the length of the second connecting hole 9 , so that the sling 10 can be fixed on the hanging plate 7 after it is looped around and passed back through the second connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com