Cable-stayed bridge cable saddle with split clamping and anchoring anti-sliding devices

A cable-stayed bridge and splitting technology, which is applied to the cable saddle field of cable-stayed bridges, can solve problems such as the detachment of the locking structure, and achieve the effects of improving the locking force, simple and reliable installation and disassembly, and stable anti-sliding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

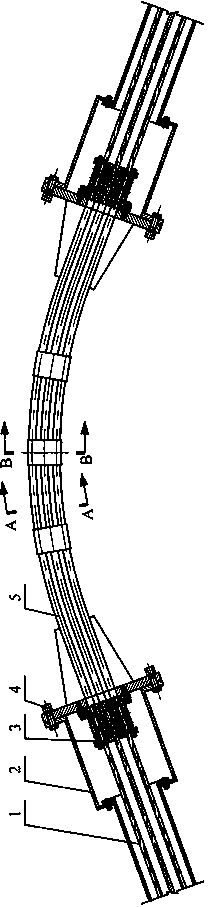

[0037] A cable-stayed bridge cable saddle with split-clamping and anchoring anti-slip devices, the cable saddle includes a split tube 5 through which 19 steel strands 1 can pass, and protective tubes arranged at both ends of the split tube 5 2. The protective tube 2 is sealed and fixed on the two ends of the split tube 5 through the connecting piece 4. The protective tube 2 is provided with a split clamping and anchoring anti-slip device 3, and the split clamping and anchoring anti-slip device 3 is connected to Part 3 35 is fixed at both ends of the split tube 5, and the 19 steel strands correspond to the 19 split tubes 5 passing through the cable saddle and the split clamping and anchoring anti-slip devices 3 at both ends, and are clamped and anchored by the split Type anti-skid device 3 is clamped and fixed.

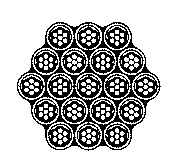

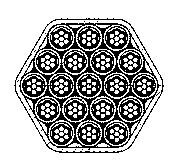

[0038] The above-mentioned wire splitting tube 5 is a circular tube, a rhombus tube or a raindrop shaped tube, and the splitting wire tube 5 can be a welding type or a...

Embodiment 2

[0045] Such as Figure 11 , 12 As shown, as a transformation of the first embodiment, the cable saddle structure of the present embodiment is generally the same as that of the first embodiment, the difference being that the six anti-sliding block splits 34 of the split clamping and anchoring anti-sliding device 3 The indirect locking is realized by connecting adjacent two anti-sliding block splits 34 . That is, the four connectors 36 can connect and fix the two adjacent anti-sliding block splits 34 in pairs.

[0046] The assembly sequence of the above-mentioned cable-stayed bridge saddle is as follows: after the first row of three steel strands 1 pass through the uppermost three wire splitting tubes, install the first piece and the second piece of the anti-sliding block split 34, and use Connecting piece 4 36 fixes the two pieces of split anti-sliding blocks 34; use connecting piece 3 35 to fix these two pieces of split anti-sliding blocks 34 and the two ends of the splittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com