Twisting device for steel rail

A technology for steel rails and torsion bending, which is applied in the field of torsion bending devices for steel rails, and can solve the problem of lack of comprehensive shaping equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

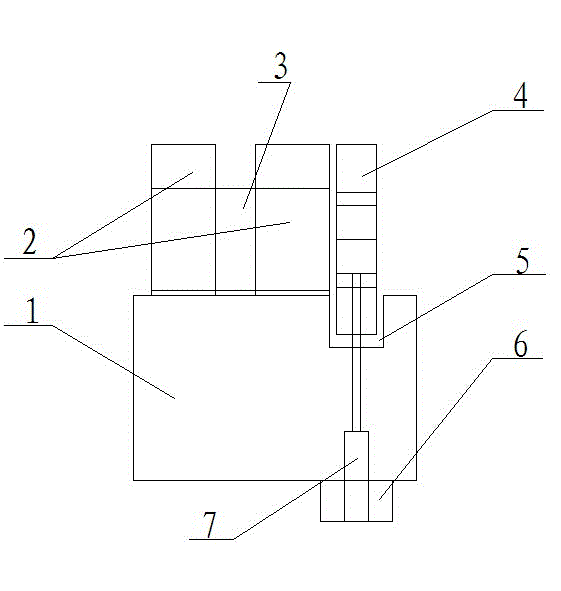

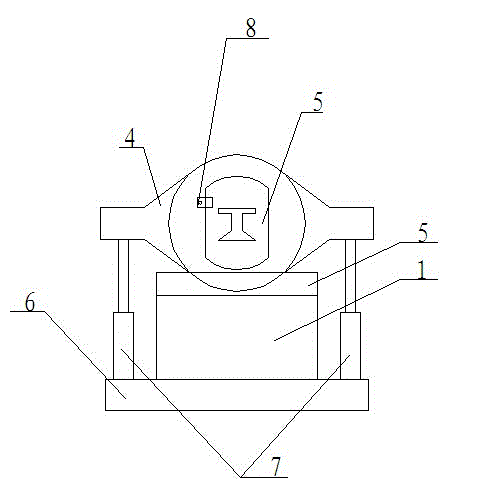

[0012] As shown in the figure, the specific implementation is as follows:

[0013] A torsion device for steel rails includes: a base 1, a base 6 for supporting the base 1, a turntable 4, and a support frame 2. The support frame 2 and the turntable 4 are arranged on the base 1 at intervals, and the turntable 4 is located on the support Between the frame 2 and the clamping mechanism 2, the support frame 2 is provided with a channel 3 for passing through and supporting the steel rail, the top of the base 1 is provided with a groove 5, and the turntable 4 has a groove extending along its diameter. 5 and suspended installation, the turntable 4 is provided with through holes distributed along its axial direction. The through hole section is a quadrilateral whose two ends are arc-shaped and the other two sides are parallel. A mold for installing the guide rail is clamped in the through hole. 5. The shape of the mold 5 matches the shape of the through hole. A pair of symmetrical ear plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com