Heat supply and cooling mixed type condenser

A condenser and hybrid technology, which is applied in the field of heating and cooling hybrid condensers, can solve the problems of limited power generation capacity of steam turbines, difficult to meet, and unable to meet heating demand at the same time, and achieve the effect of ensuring power generation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

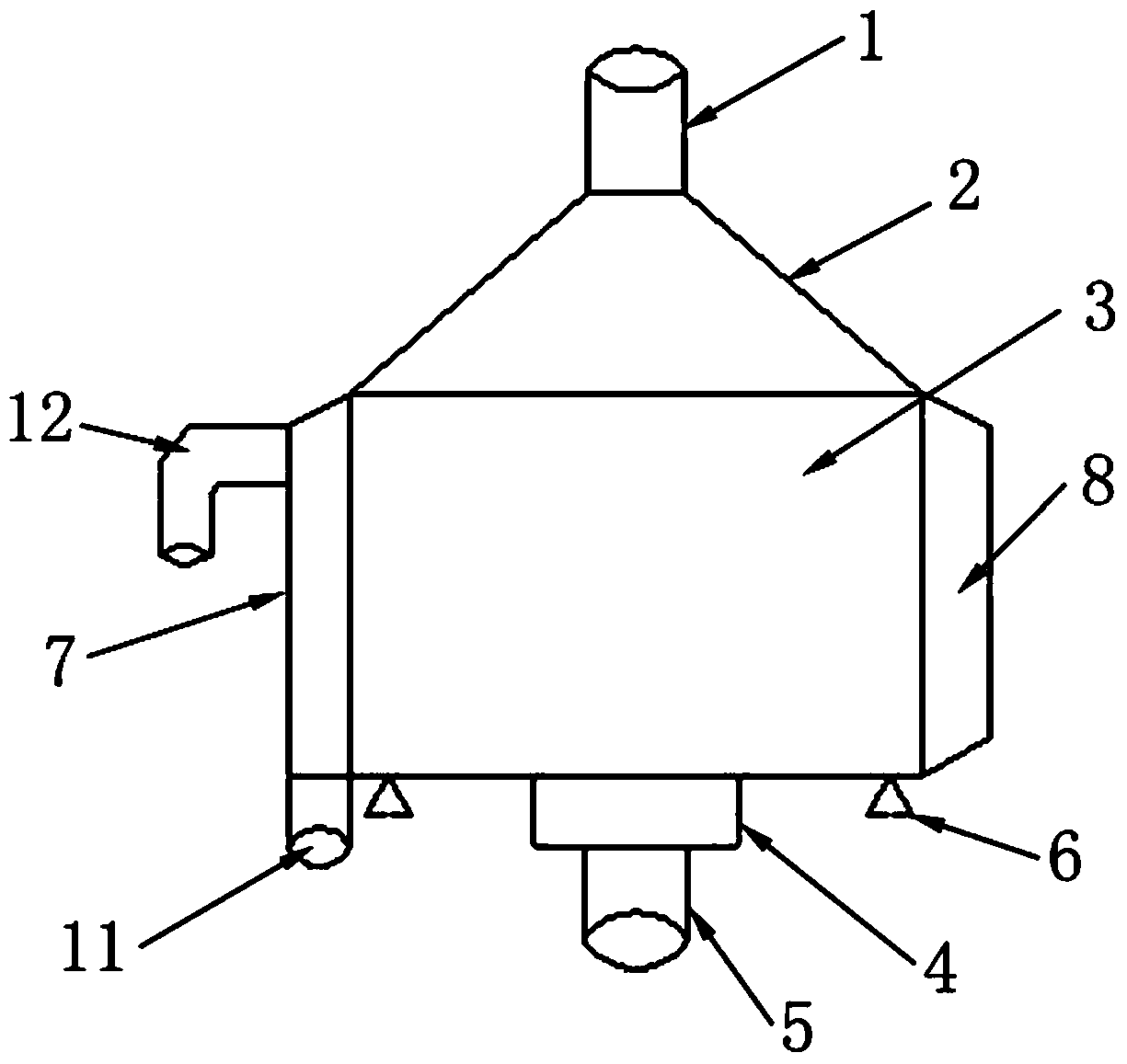

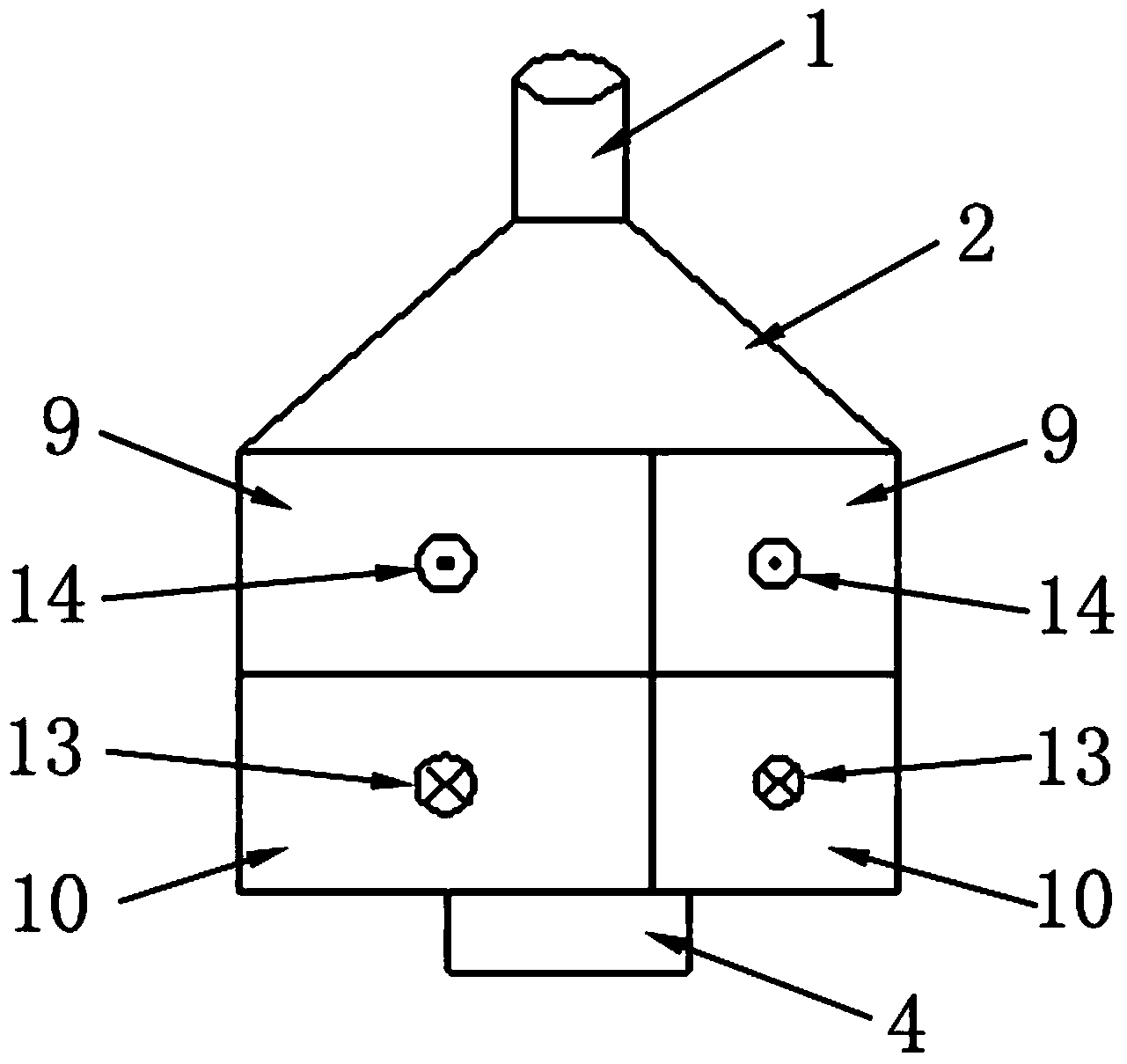

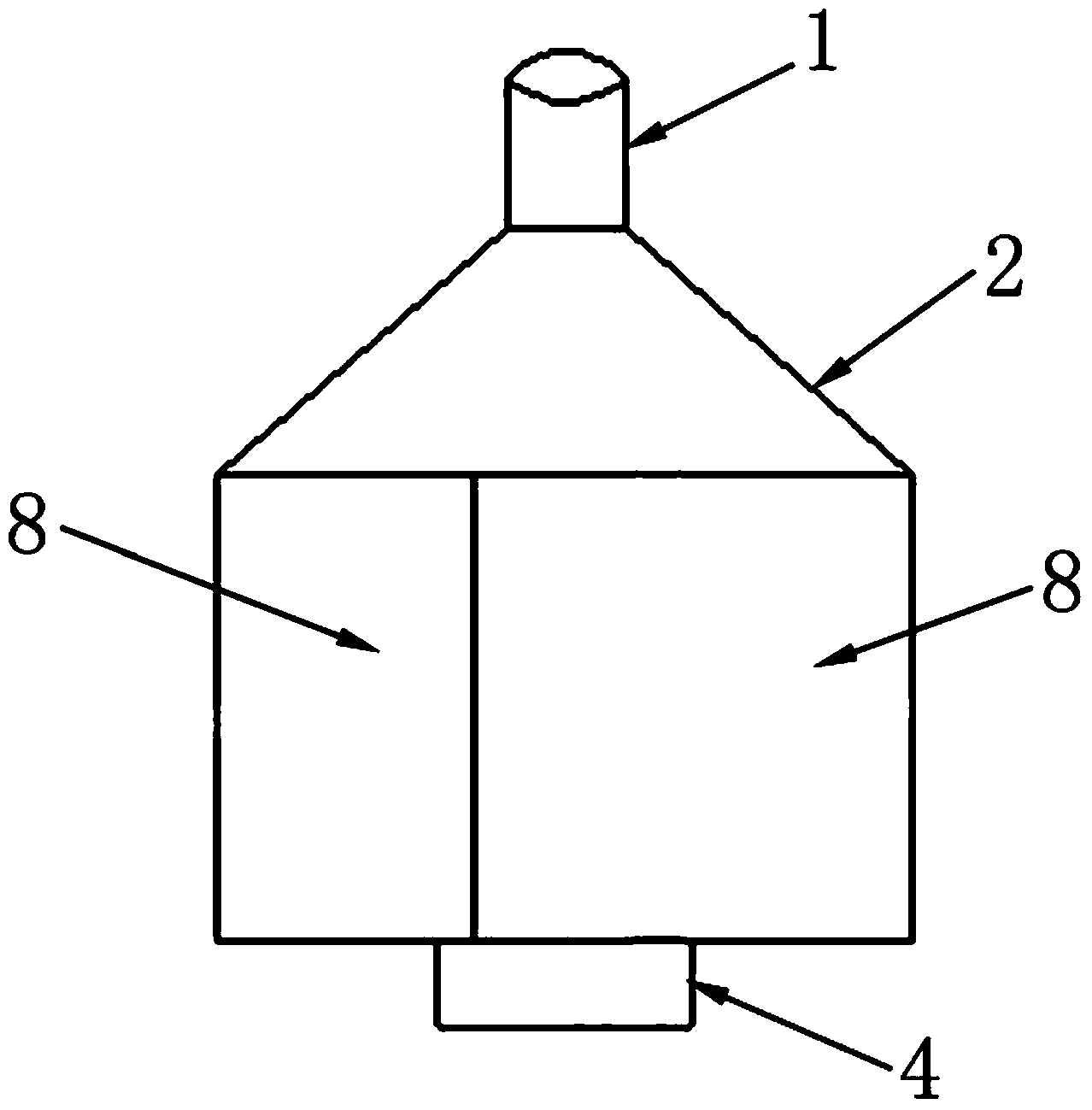

[0021] like Figure 1-3 As shown, a heating and cooling hybrid condenser of the present invention includes a shell 3, the inside of which is empty; the upper end of the shell 3 is connected with a steam inlet pipe 1, and its lower end is connected with a drain pipe 5 , the housing 3 is connected with at least two groups of heat exchange units, the heat exchange units are connected with circulating water, the circulating water can be cooling circulating water, or heating network circulating water from the heating network; the heat exchanging unit includes: the front water chamber 7. The rear water chamber 8 and multiple heat exchange tube bundles, the front water chamber 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com