Rapid high-water material strength detector and using method thereof

A technology of strength detection and high water material, which is applied in the direction of using one impact force to test the strength of the material, which can solve the problem of high water material debris generation and filling the hole wall, difficulty in measuring penetration depth, and the inability of measuring tools to measure and measure well. Hole and other problems, to achieve the effect of all-round multi-angle measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A preferred mode will now be described in detail below. It should be noted that the present invention is not limited to this embodiment, on the contrary, the present invention also covers various aspects within the spirit and scope of the present invention within the scope of the claims. alternatives, modifications, equivalents and other implementations.

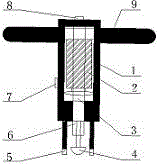

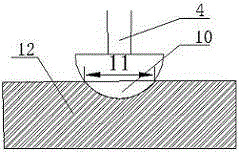

[0027] According to a preferred embodiment of the present invention, as attached figure 1 As shown, the detector involved in the present invention includes the following main parts: 1. The main body of the bracket; 2. The power box; 3. The penetrating rod; 4. The spherical crown probe; Seat; 7. Power excitation button; 8. Detection start button; 9. Handle. Among them, the bracket main body 1, the spacer 5 and the handle 9 constitute the bracket system, the power box 2, the power excitation button 7, and the detection start button 8 constitute the power system, and the penetrating rod 3, the spherical crown probe 4 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com