Double-saw-blade reciprocating saw

A double saw blade reciprocating saw and saw blade technology, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problem of unsuitable single-handed operation, unsuitable operation in a narrow space, long shape of double saw blade reciprocating saw, etc. and other issues, to achieve the effect of weight reduction, reduction of wear damage, and shortening of the overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

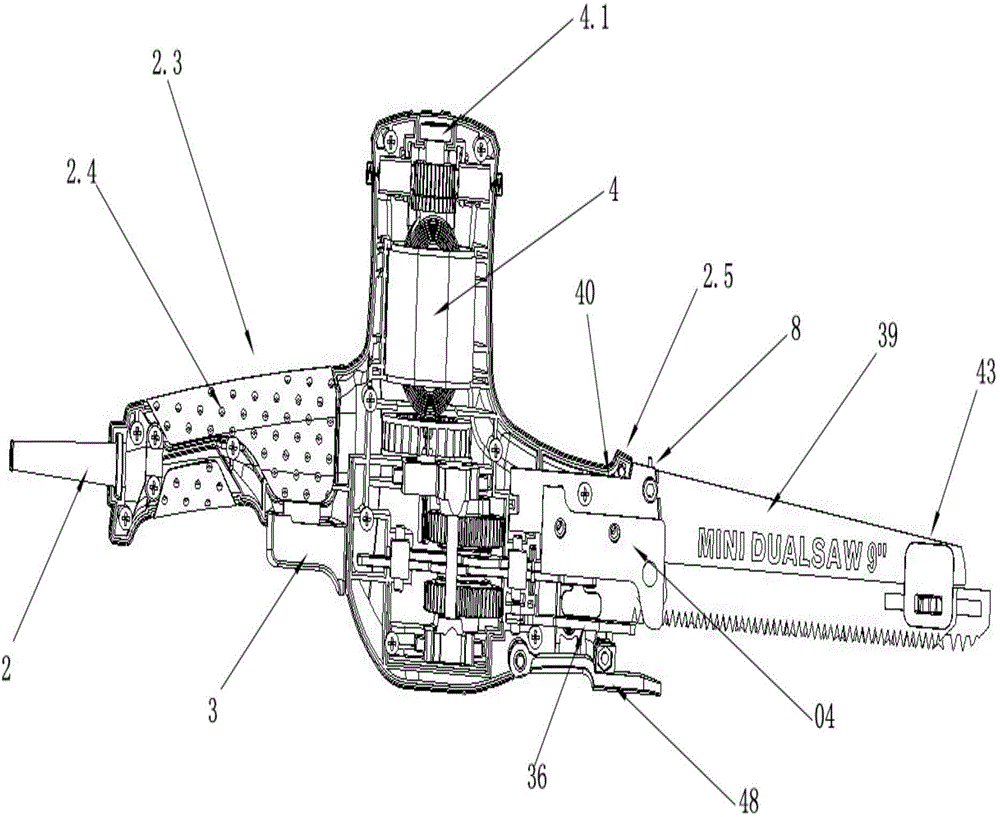

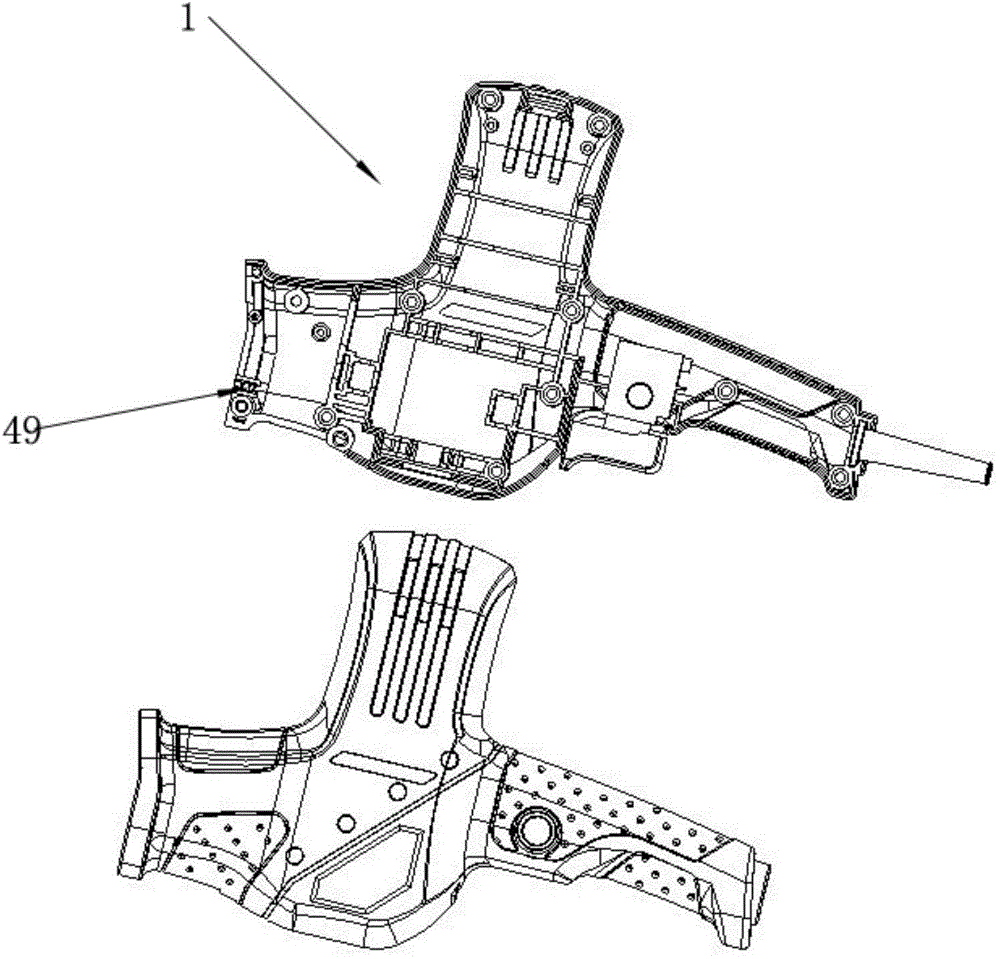

[0033] A kind of double saw blade reciprocating saw of the present invention such as Figures 1 to 9 As shown, it includes a plastic housing 1, the housing includes a first housing 2.1 and a second housing 2.2, the rear part 2.3 of the housing 1 is set as a hand-held part 2.4 and a positioning wire barrel 2 for the cable to move out , the switch button 3 for the user to turn on the power. The first reciprocating rod 5 and the second reciprocating rod 6 arranged in a vertical distribution, and the guide rail 33 sleeved in the first reciprocating rod and the second reciprocating rod, preferably, the guide rails in this embodiment are set to two, respectively The front guide rail 34, the rear guide rail 35, the front guide rail and the rear guide rail respectively cover the first reciprocating rod and the second reciprocating rod before and after. The motor 4 and the transmission mechanism 7 arranged in the housing, the saw blade clamping mechanism 8 arranged at the front end 2....

Embodiment approach 2

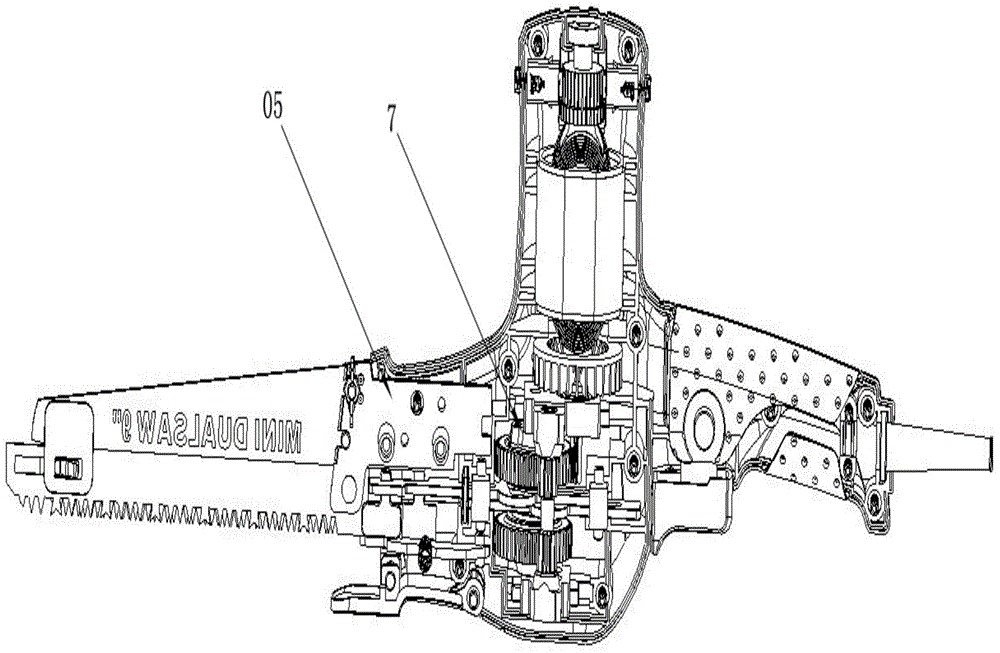

[0039] Such as Figure 10 , 11 As shown, the second embodiment is basically the same as the first embodiment, the difference is that the transmission mechanism 7 in this embodiment includes a bracket 100 arranged at an oblique angle, the main shaft 101 arranged on the bracket is arranged on the The bevel gear 102 on the main shaft is arranged on the double eccentric wheel 103 on the said bevel gear, and the said double eccentric wheel 103 comprises an upper eccentric wheel 104 and a lower eccentric wheel 105 arranged symmetrically with respect to said main shaft, and the bevel gear is provided with a shaft Hole 111, a first eccentric hole 112 is opened on the upper eccentric wheel, a second eccentric hole 113 is opened on the lower eccentric wheel, and the main shaft passes through the shaft hole, the first eccentric hole and the second eccentric hole in sequence. The upper eccentric wheel and the lower eccentric wheel are fixed to each other, the upper eccentric wheel 104 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com