Multi-layer chain transmission cooling device for food

A technology of a cooling device and a chain drive mechanism, which is applied to cooling fluid circulation devices, household refrigeration devices, coolers, etc., can solve the problem of increasing the manufacturing cost of the cooling box 1, increasing the energy loss of the cooling airflow, increasing the components and production costs, etc. problems, to achieve the effect of improving cooling efficiency and cooling effect, reducing energy loss, and reducing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

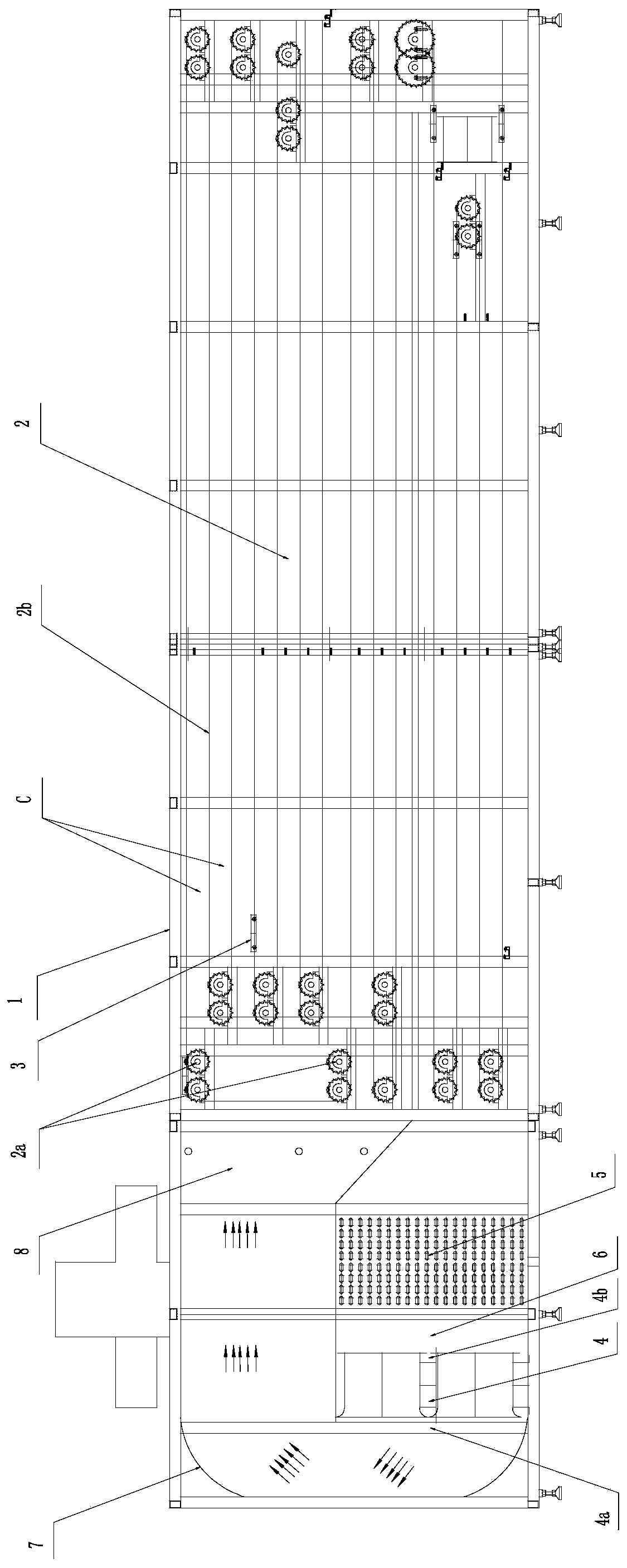

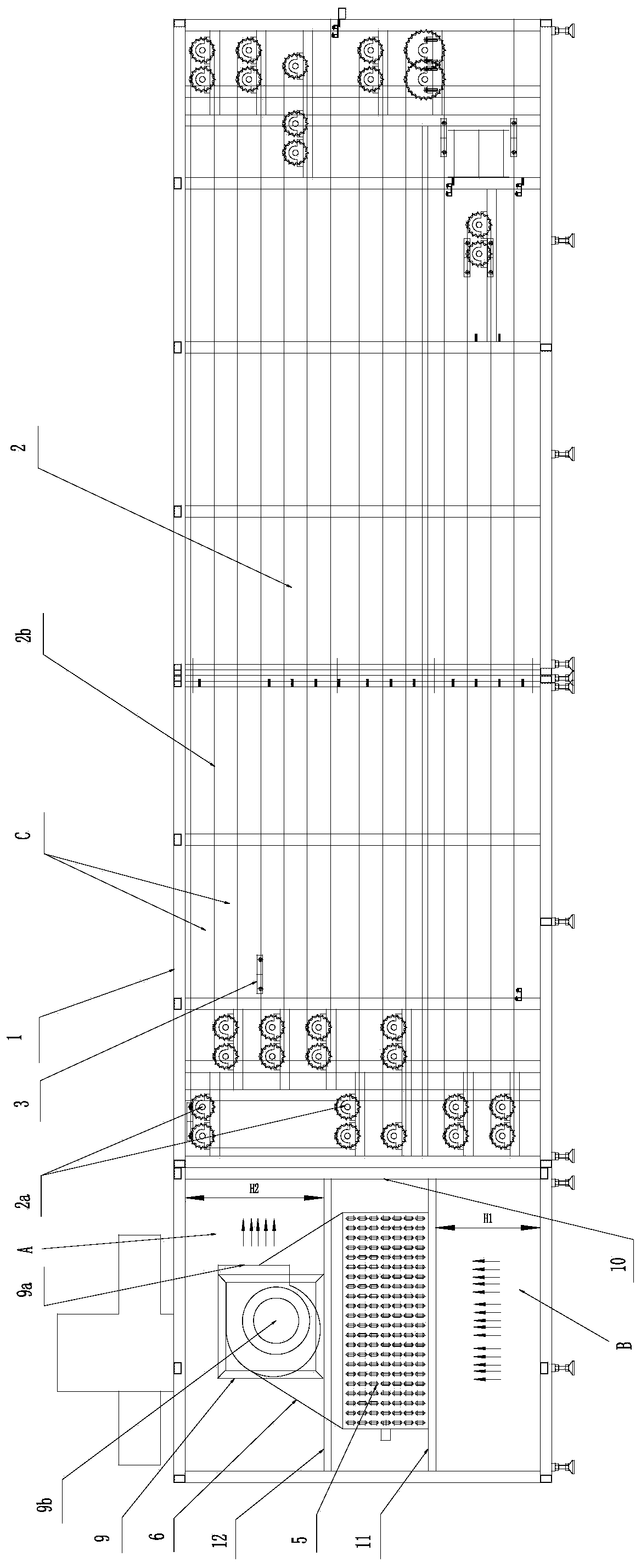

[0024] Embodiment: combine below figure 2 Shown, this specific implementation mode provided by the present invention is described in detail as follows:

[0025] combine figure 2 This food multi-layer chain transmission cooling device provided by the present invention has a cooling box 1 and a multi-layer chain transmission mechanism 2 and a refrigeration mechanism located in the cooling box 1 as in the conventional technology, and the refrigeration mechanism is located in the multi-layer chain transmission. Agency 2 side. The difference is that we have improved the refrigeration mechanism, which is composed of a centrifugal fan 9, an evaporator 5 and an air guide cover 6. The cooling box 1 is provided with a support frame 10 between the multi-layer chain transmission mechanism 2 and the refrigeration mechanism. The support frame 10 and the inner wall of the cooling box 1 opposite to it are fixed with a first partition arranged from bottom to top. 11 and the second partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com