Valve core component of corrugated pipe type double-base sleeve valve

A spool component and bellows technology, applied in the structural field of double-seat sleeve valve spool components, can solve the problems of unreliable medium sealing and large leakage, achieve reliable effect, reduce shape and position tolerance requirements, uniform ratio pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

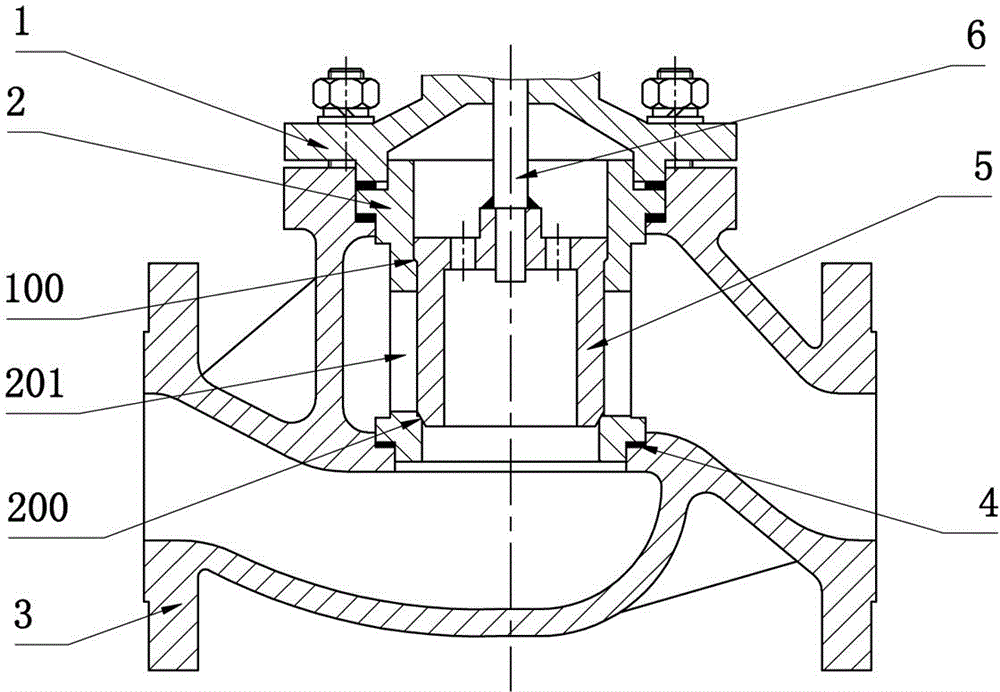

Embodiment 1

[0026] Embodiment one: if image 3 As shown, the two ends of the bellows are respectively connected to the upper valve core body and the lower valve core body with a sealing contact surface to form a composite valve core with two sealing contact surfaces. Both valve core bodies are provided with medium passage holes. The valve stem and the upper valve core body are connected by the split ring on the valve stem and the inner hexagon nut to form a valve core assembly. The lower valve core body of the valve core assembly is a free end and adopts a ring structure.

[0027] In this connection, the valve stem and the composite valve core can be rotated to meet the needs of the actuator connected to the valve when the valve stem needs to be rotated, such as manual actuators and multi-turn automatic actuators.

[0028] When the valve with this spool assembly structure is closing, the spool assembly moves down as a whole. First, the lower sealing contact surface contacts the sealing co...

Embodiment 2

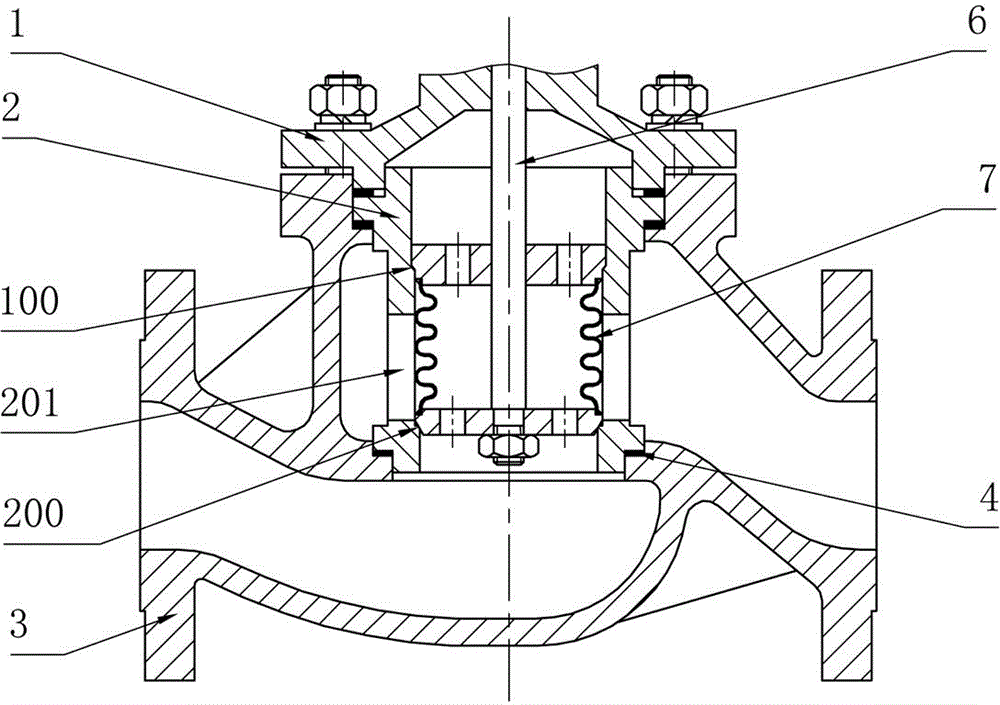

[0030] Embodiment two: if Figure 4 As shown, the two ends of the bellows are respectively connected to the upper valve core body and the lower valve core body with a sealing surface to form a composite valve core with two sealing contact surfaces. Both valve core bodies are provided with medium passage holes. The stem is welded on the upper valve core body to form a fixed connection to form a valve core assembly. The valve stem extends downward for a section and forms a sliding fit with the lower valve core body to reduce vibration. The lower valve core body adopts a sliding fit Mesopore structure.

[0031] The closing action of the valve and the state of the bellows at maximum opening and closing are the same as those in the first embodiment.

Embodiment 3

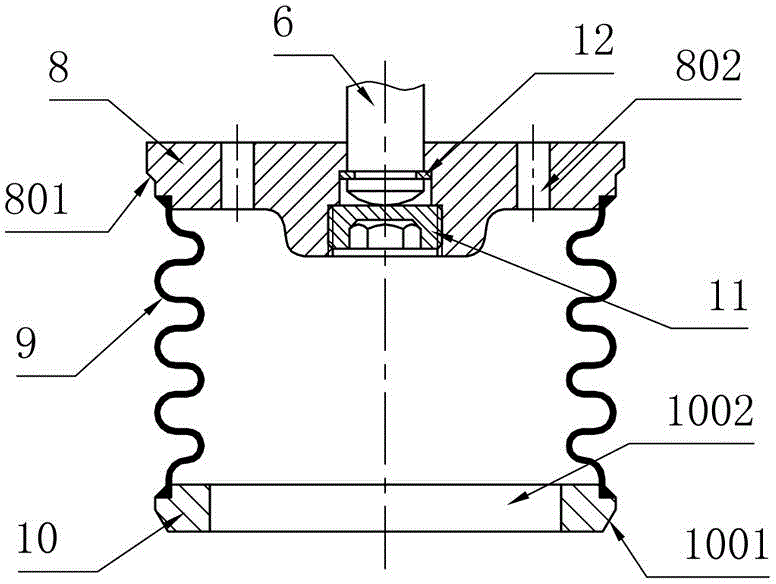

[0032] Embodiment three: as Figure 5 As shown, the two ends of the bellows are respectively connected to the upper valve core body and the lower valve core body with a sealing contact surface to form a composite valve core with two sealing contact surfaces. Both valve core bodies are provided with medium passage holes. It is set on the valve stem, and then fixedly connected with the nut 13 through the thread on the valve stem, so that the composite valve core is positioned on the axial direction of the valve stem when the lower valve core body and the valve stem are in a sliding fit state. The bellows should be pre-compressed. It is also possible to add an adjustment sleeve 14 set on the valve stem to adjust the two lengths so that the recompression of the bellows when the valve is closed is as small as possible, which can save space to the greatest extent and improve the valve's alignment. The sensitivity of the motion response of the spool assembly.

[0033] The closing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com