Short circuit simulation test circuit and test method thereof

A technology for simulating tests and circuits, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of long action time, high voltage, large current, etc., and achieve the effect of favorable safety, convenient implementation and simple control.

Inactive Publication Date: 2015-03-18

NR ELECTRIC CO LTD +1

View PDF6 Cites 348 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The system voltage is high, the current is large, and the capacity is large. It is difficult to build a full-load circuit in the test environment that is the same as the actual operating condition for testing. Therefore, how to build an equivalent test circuit in the test environment to test the strength of the actual operating Quite experimentation becomes the key to solving the problem

[0003] In the actual operation of high-power power electronic devices based on turn-off device valves,

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

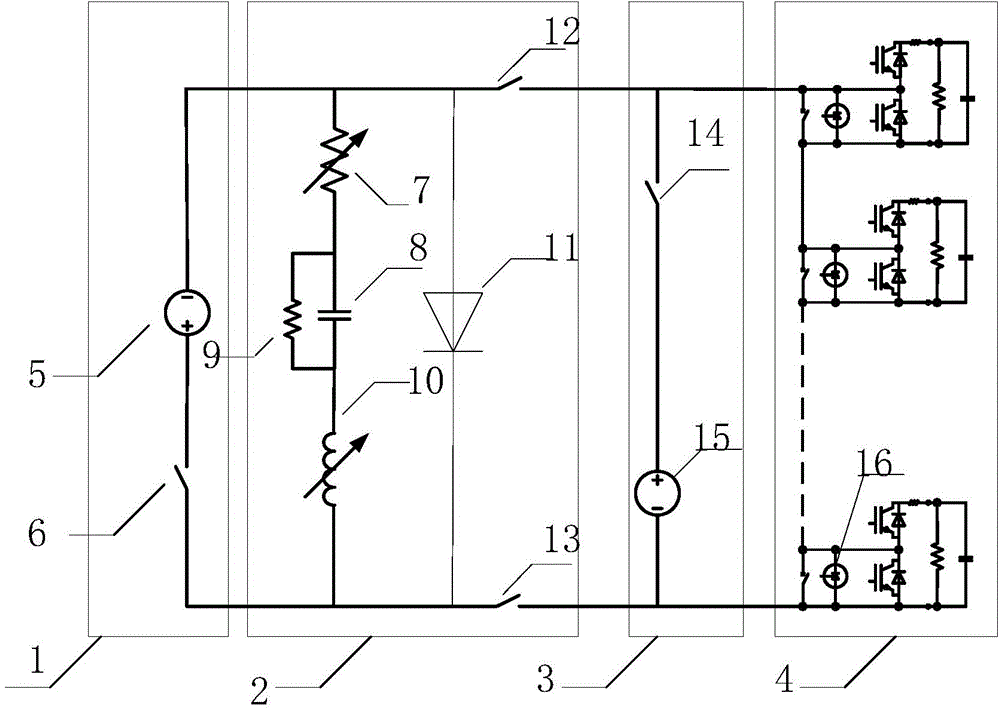

The invention discloses a short circuit simulation test circuit which is used for testing and examining the operation condition of a converter valve. The short circuit simulation test circuit comprises a capacity charge power supply module, a fault current generation circuit and a converter valve charging source module, wherein the cathode of the capacity charge power supply module is connected with a positive input end of the fault current generation circuit while the anode of the capacity charge power supply module is connected with a negative input end of the fault current generation circuit; a positive input end of the fault current generation circuit is connected with the anode of the converter valve charging source module and a high voltage output end of the converter valve respectively, and the negative output end of the fault current generation circuit is connected with the cathode of the capacity charge power supply module and the low voltage output end of the converter valve respectively. The test circuit can be used for testing and examining the fault operation condition of converter value. The invention further discloses a test method of the short circuit simulation test circuit.

Description

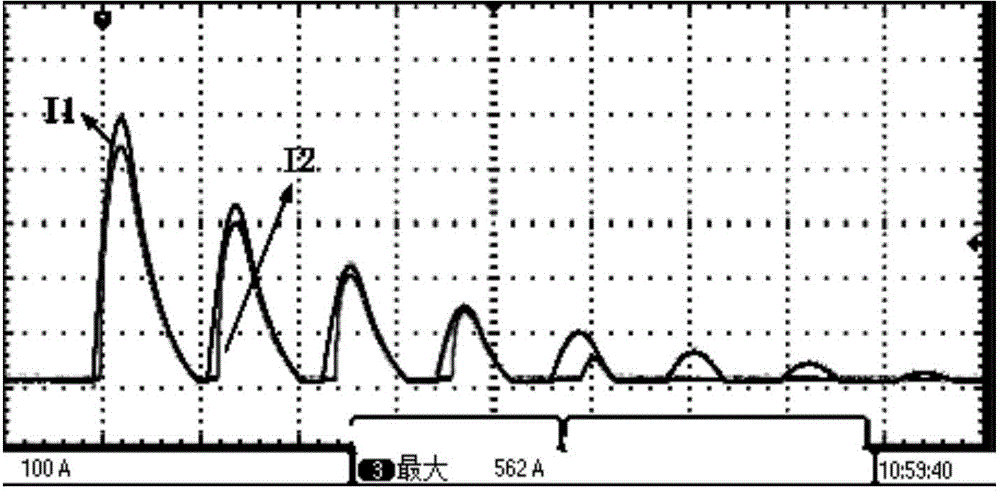

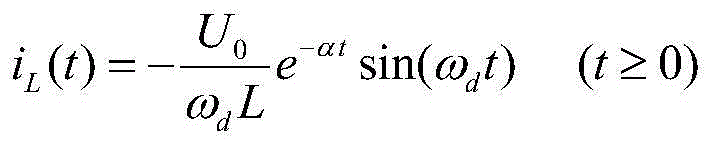

technical field [0001] The invention relates to an operation test method of high-power electric electronic technology, in particular to a short-circuit simulation test circuit and a test method. Background technique [0002] With the application of high-power power electronic converter technology in the power system, the reliability of its core component, the converter valve, becomes the key to system safety. The system voltage is high, the current is large, and the capacity is large. It is difficult to build a full-load circuit in the test environment that is the same as the actual operating condition for testing. Therefore, how to build an equivalent test circuit in the test environment to test the strength of the actual operating Quite experimentation becomes the key to solving the problem. [0003] In the actual operation of high-power power electronic devices based on turn-off device valves, the anti-parallel diode overcurrent of the insulated gate bipolar transistor (...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01R31/02

Inventor 连建阳姜田贵朱铭炼谢晔源段军殷冠贤

Owner NR ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com