Furnace top gas sealing device for optical fiber drawing

A furnace top gas and wire drawing technology, used in glass fiber drawing devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as poor consistency and stability, increase of tower height and rod feeding stroke, inconvenient disassembly and assembly of furnaces, etc. problem, to achieve the effect of simple structure, large diameter variation range and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

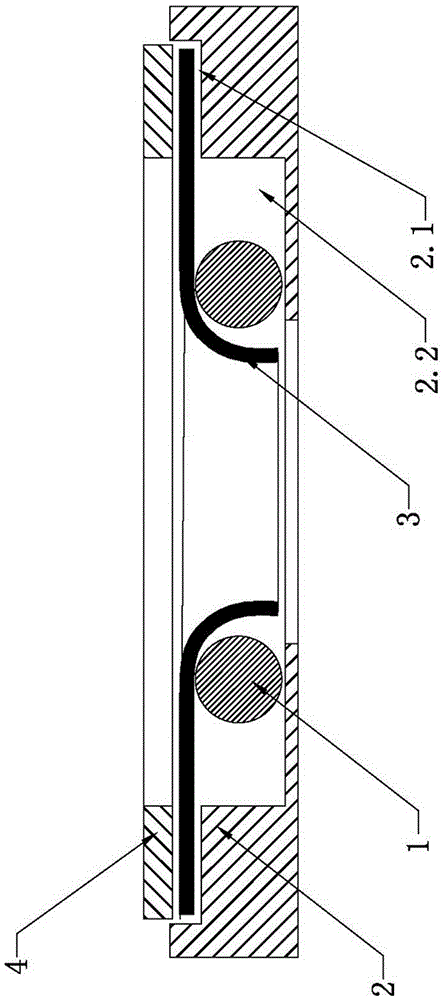

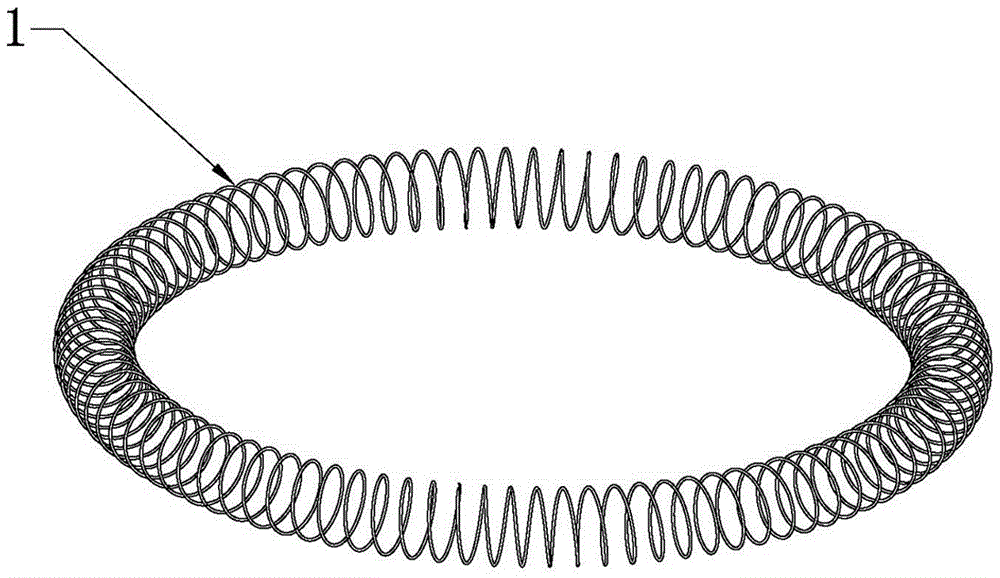

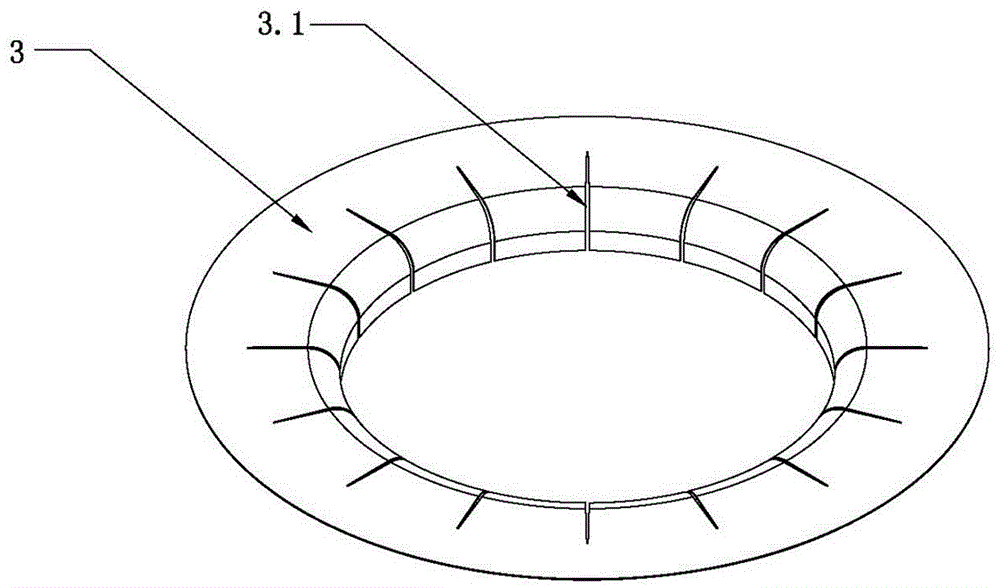

[0015] Such as figure 1 , figure 2 with image 3 As shown, a furnace top gas sealing device for optical fiber drawing is characterized in that it includes a self-tightening spring 1, an annular bottom plate 2, a graphite gas sealing ring 3 and an upper pressure ring 4; on the annular bottom plate 2 are sequentially arranged from the outside to the inside. A high notch 2.1 and a low notch 2.2 are provided with a number of equally divided slits 3.1 along the circumferential direction at the inner ring opening of the graphite gas sealing ring 3; after stacking several graphite gas sealing rings 3, the graphite gas sealing ring 3 The outer side is arranged on the high notch 2.1 and pressed by the annular bottom plate 2, and the self-tightening spring 1 is arranged at the low notch 2.2 on the lower side of the inner ring opening of the graphite gas sealing ring 3.

[0016] The working principle of the present invention is as follows Figure 4 As shown, the present invention is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com