Iris diaphragm

A diaphragm and variable technology, applied in the direction of aperture, optics, camera, etc., can solve the problems of small variable range and complex design of the iris diaphragm, and achieve the effect of simple structure, stable change of round hole, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

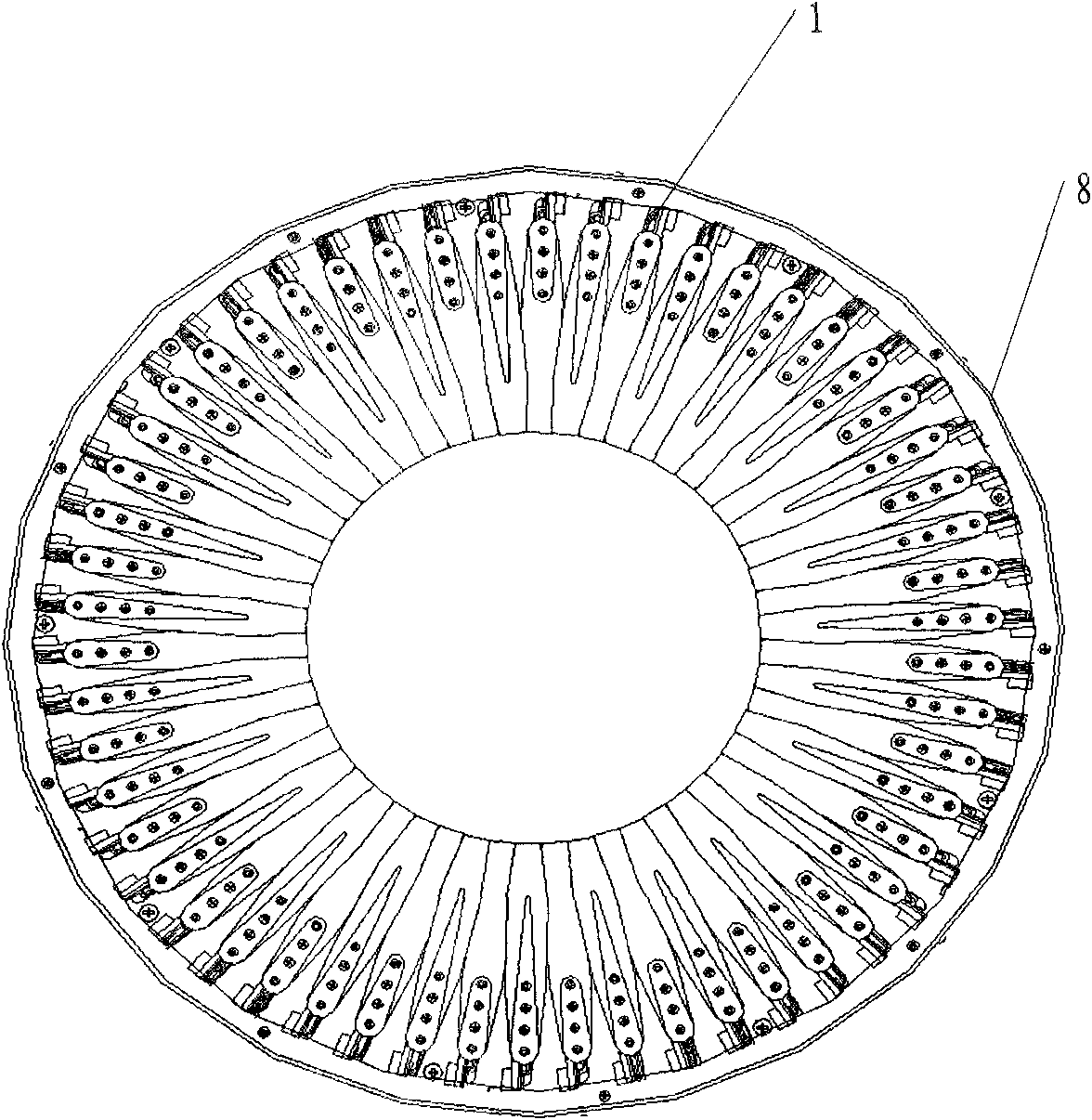

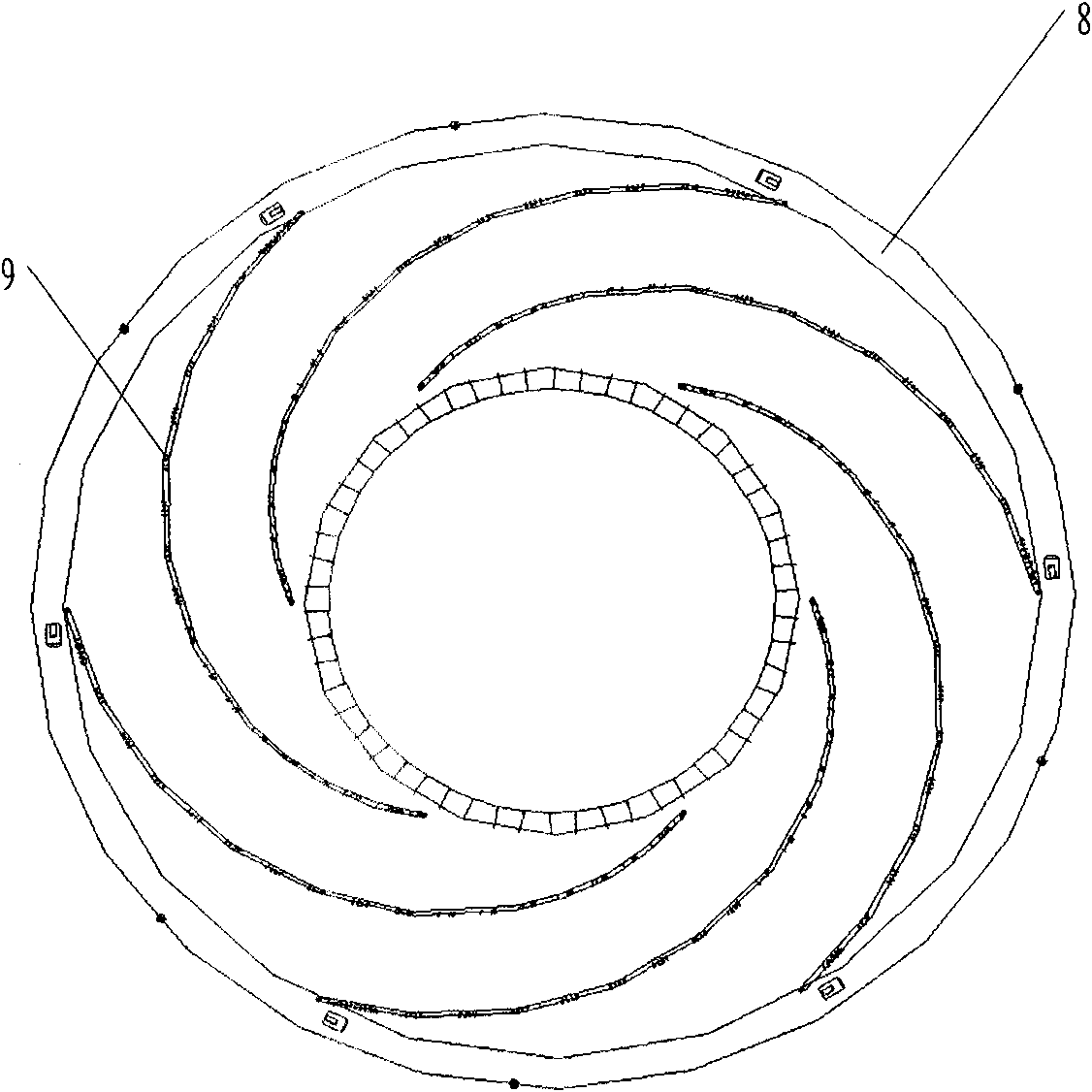

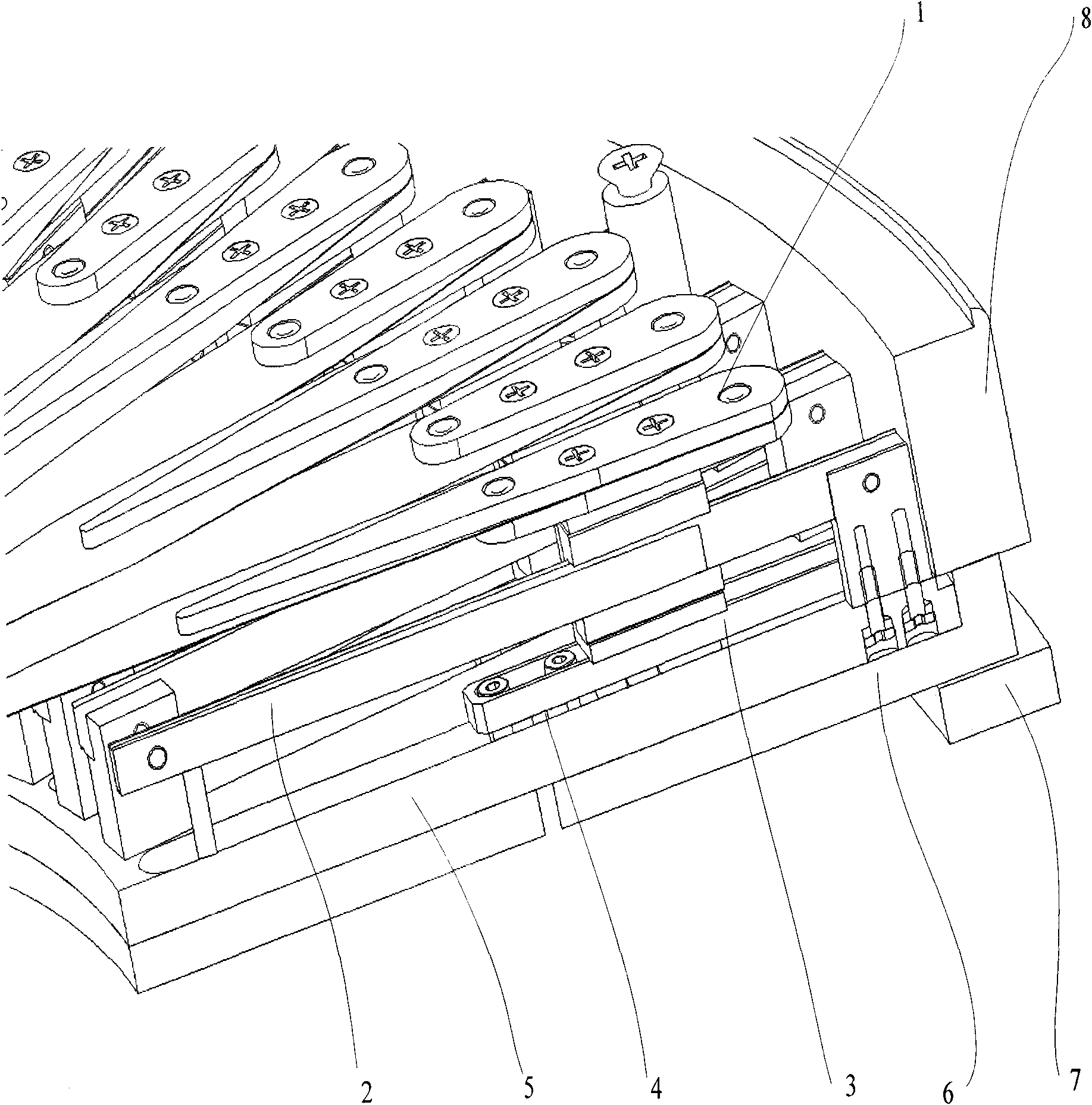

[0027] The present invention proposes a variable aperture, comprising: a support frame; a rotating disk connected to the support frame, a plurality of sliding grooves are arranged in the rotating disk, and the sliding grooves are involute arc sliding grooves; The mounting plate is connected to the rotating disk; the moving guide rail combination is fixed on the mounting plate; multiple sets of blade combinations are located on the moving guide rail combination, and the blade combinations are interlaced and superimposed on each other, and all adjacent ones Both ends of the blade combination are connected, and multiple groups of the blade combination form a ring structure, and the blade combination includes: a reinforcement plate; a blade connected to the reinforcement plate; a positioning plate connected to the blade; a connecting plate, and The positioning plate is connected; the guide rail sliding sleeve is connected with the connecting plate; the screw is fixed on the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com