Automatic capping device of filling machine

A filling machine, automatic technology, applied in packaging, bottle filling, liquid bottling and other directions, can solve the problems of inaccurate manual operation, the quality of the upper cover is not up to standard, and there are dead corners in the walking process, and the upper cover is flexible and accurate. , Improve the efficiency of the cover and ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

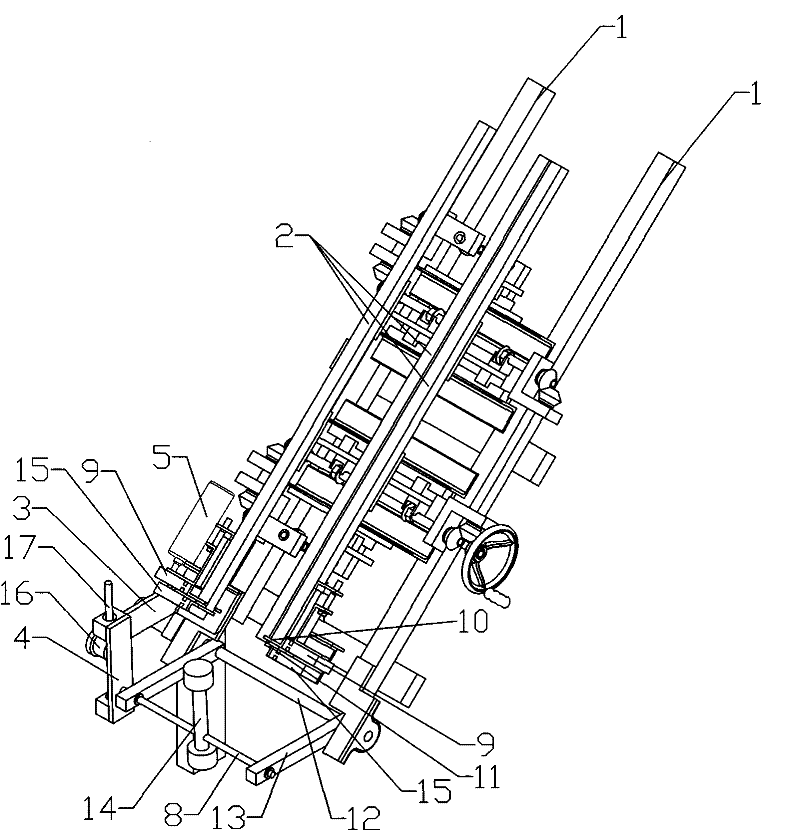

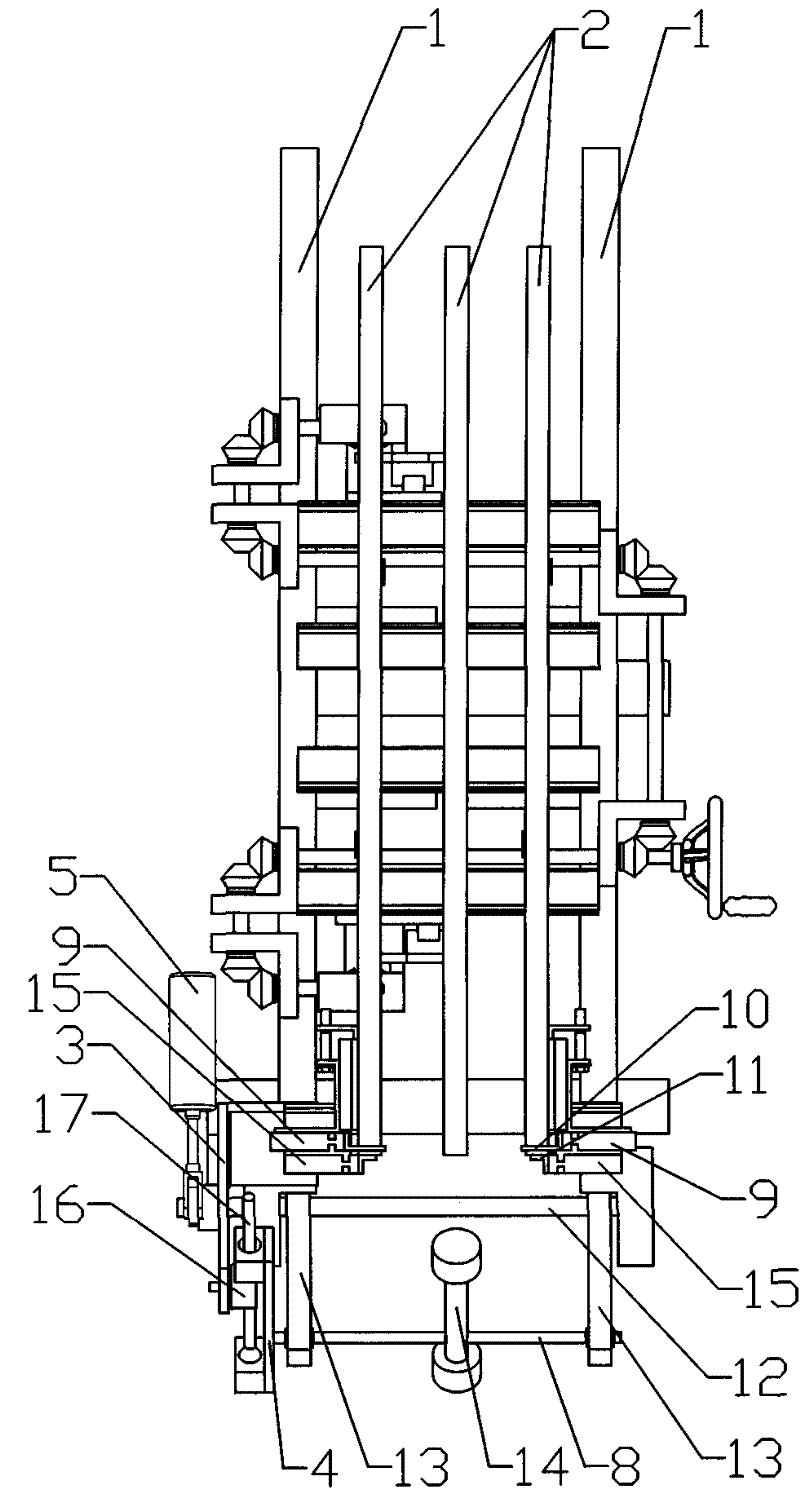

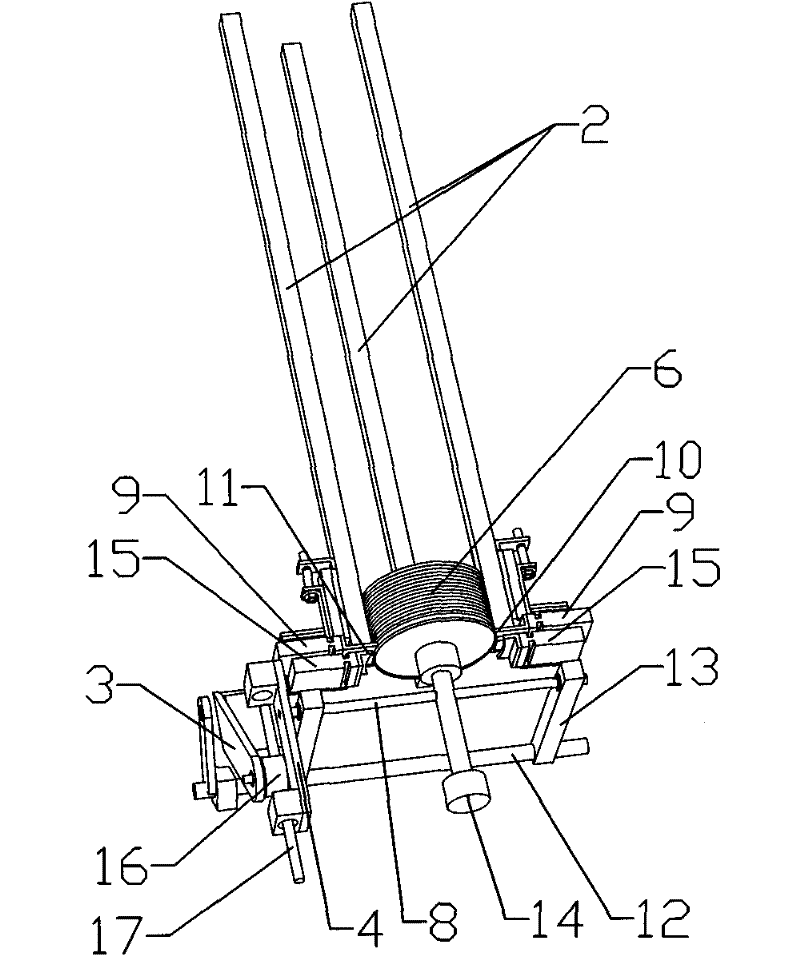

[0033] Examples such as figure 1 , figure 2 As shown, an automatic capping device for a filling machine includes a cap bracket 1 on which a cap clamping guide device and a cap rotating device are arranged.

[0034] The lid clamping guide device includes three clamping guide rods 2 parallel to the upper cover bracket 1, the three clamping guide rods 2 are arranged in an inverted triangle, and the clamping guide rods 2 are arranged near the end of the bung turning device There are a blocking knife 11 for blocking the bung and a separating knife 10 for separating the bung. There are two blocking knives 11, which are arranged symmetrically at the ends of the two clamping guide rods 2 arranged above. Department; the blocking knife is connected to the blocking cylinder 9, which is controlled by the blocking cylinder 9 to slide along the transverse section direction of the clamping guide rod 2. There are two separating knives 10, which are arranged symmetrically at the ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com