Phase calibration method of current measuring for induction logging

A technology of current measurement and induction logging, which is applied in the directions of measurement, earthwork drilling, borehole/well components, etc. It can solve problems such as inability to locate the source, difficulty in problem analysis, and insufficient stability of the imaginary part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

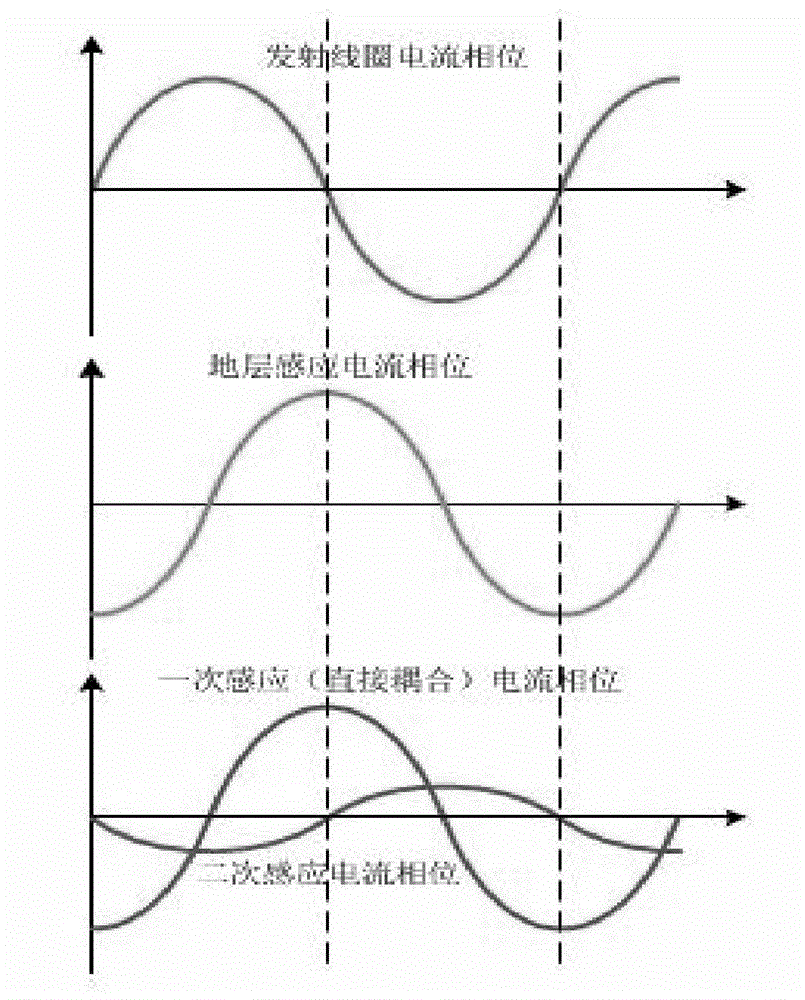

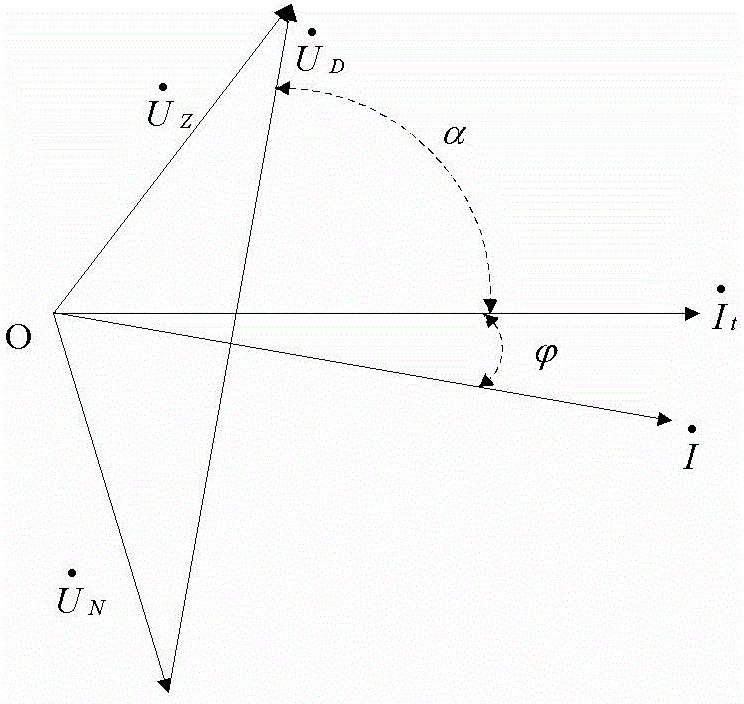

[0042] The phase calibration method of the current measurement of the present invention assumes that the slight change of the distance between the transmitting coil and the receiving coil only affects the imaginary part of the apparent conductivity, and the influence on the real part can be ignored, and the difference between the measured apparent conductivity vector and The current vector is vertical, and the phase difference with the actual measured current vector can be used as the correction amount of the current measurement phase.

[0043] Hereinafter, the phase calibration method for current measurement of the present invention will be described in detail.

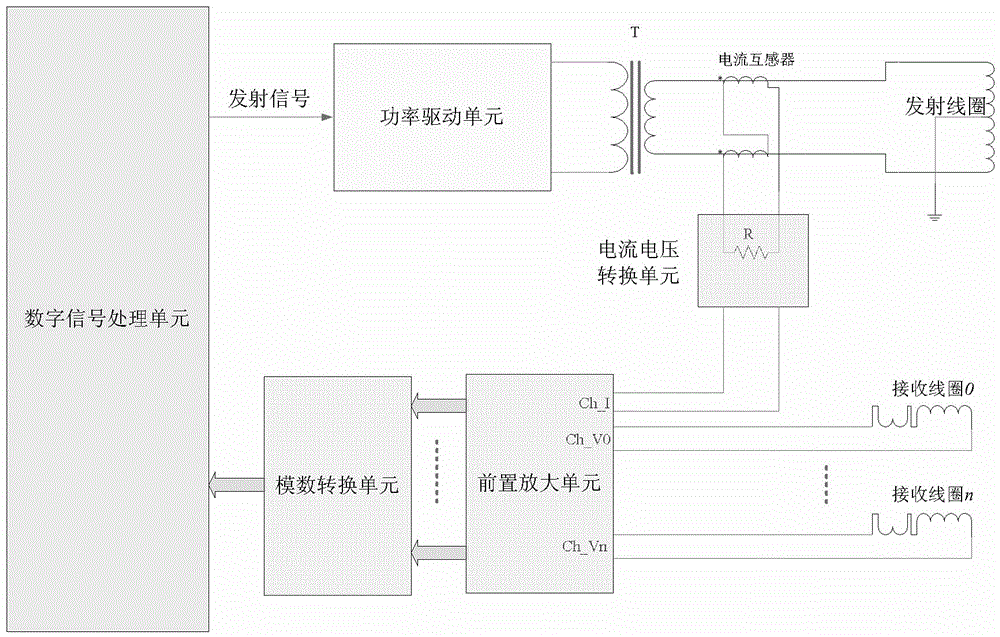

[0044] attached image 3 System block diagram for current measurement of a 3D array induction logging tool. as attached image 3 As shown, the digital signal processing unit (abbreviated as DSP) of the three-dimensional array induction logging tool uses the direct digital frequency synthesis technology to generate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com