A self-cleaning manual flush valve

A technology of self-cleaning and flushing valves, applied in safety valves, balance valves, valve devices, etc., can solve the problems of deep orifice, inconvenient, troublesome handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

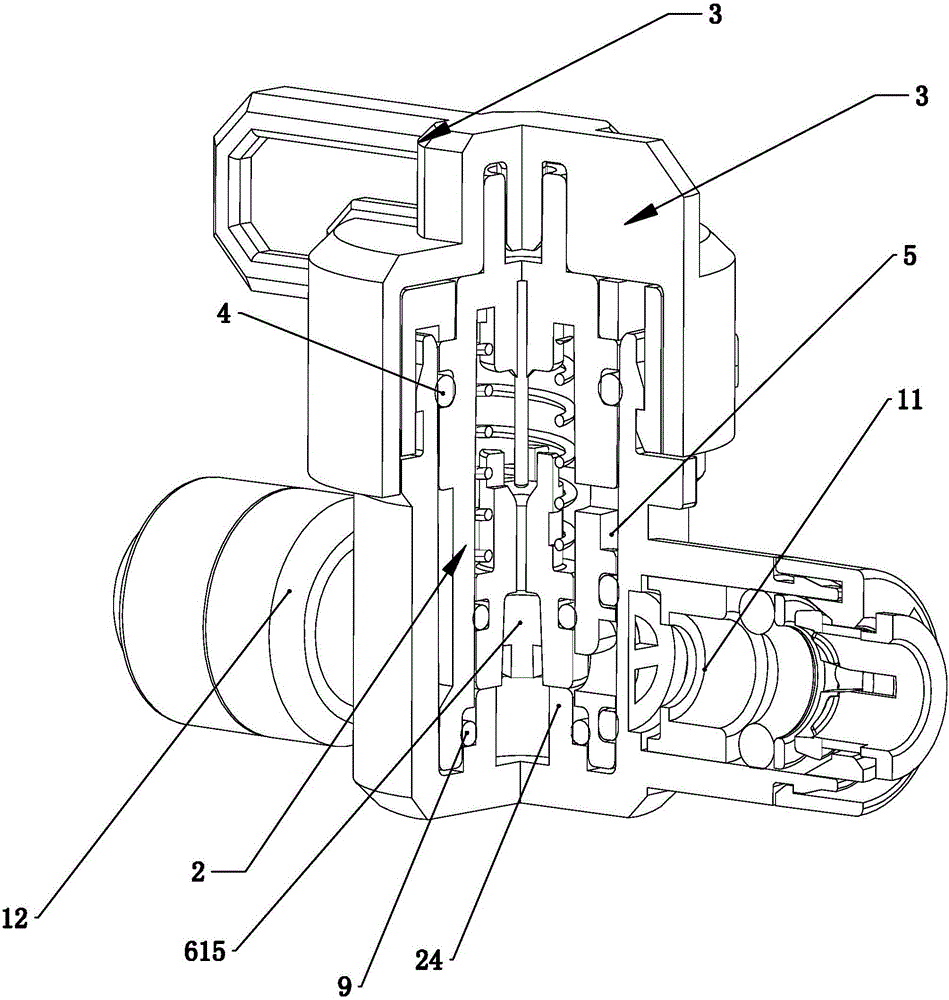

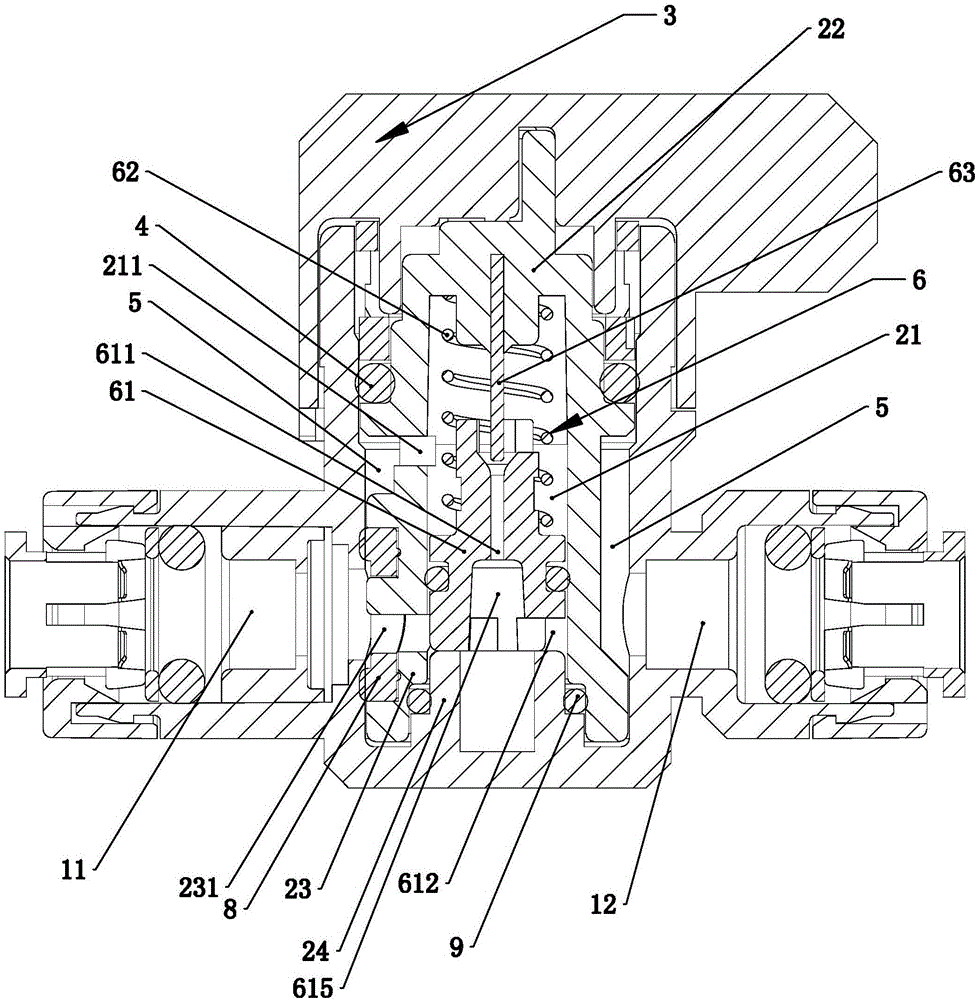

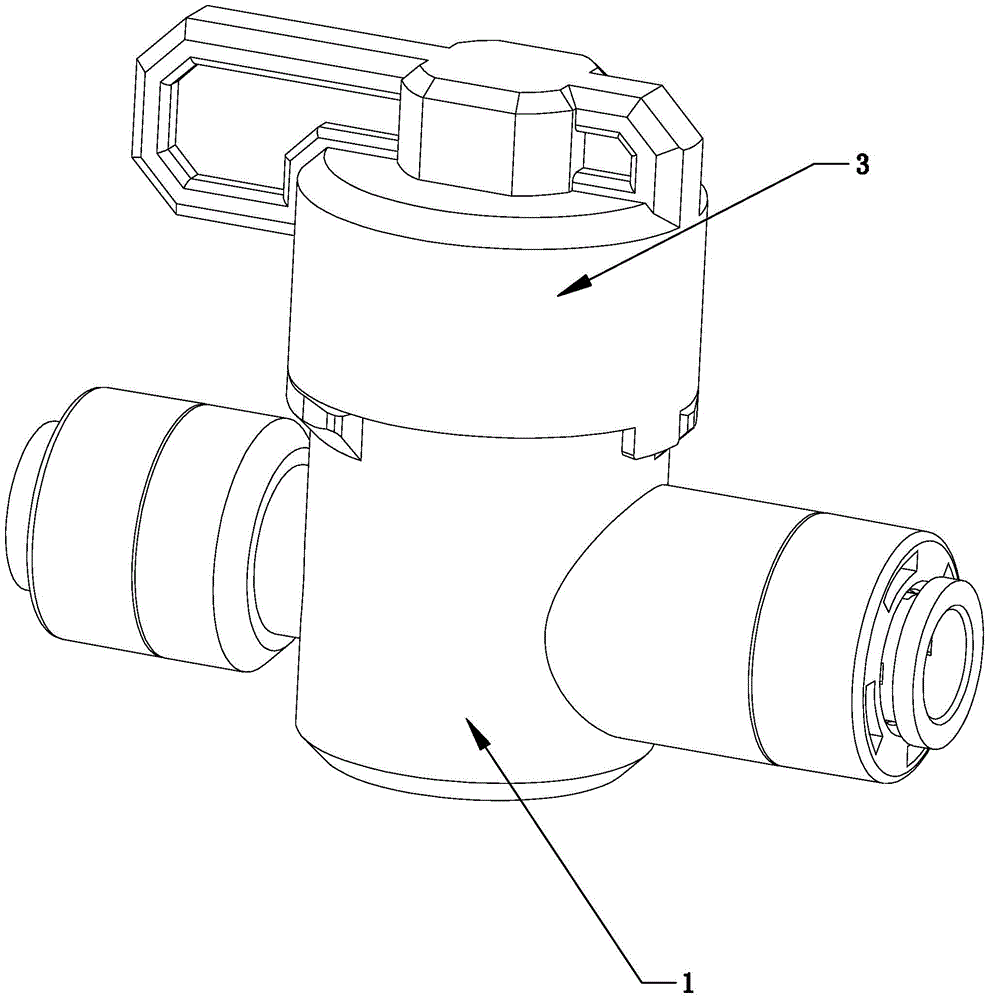

[0014] Such as figure 1 — Figure 5 As shown, a self-cleaning manual flush valve includes a valve body 1, a valve core 2 and a handle 3, the valve body 1 is provided with a water inlet channel 11 and a water outlet channel 12, and the valve core 2 is arranged on the valve body 1, the handle 3 controls the rotation of the spool 2. In this embodiment, the middle part of the spool 2 is hollowed to form a hollow part 21, and the upper end of the spool 2 close to the handle 3 is a closed end 22. The spool 2 Boss 23 is arranged on it, and water inlet 231 is arranged on this boss 23, and when the water inlet 231 of boss 23 is aligned with the water inlet channel 11 on the valve body 1, the water inlet channel 11 only connects with the water inlet 231, so that the water Only the water inlet can enter, the valve core 2 is located between the top of the boss 23 and the inner wall of the valve body 1, and a second sealing ring 4 is arranged, and the valve core 2 is located below the sec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap