Method of testing semiconductor device and apparatus of testing semiconductor device

An inspection method and inspection device technology, applied in the field of inspection of semiconductor devices and inspection devices of semiconductor devices, to achieve the effect of accurate good or bad judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

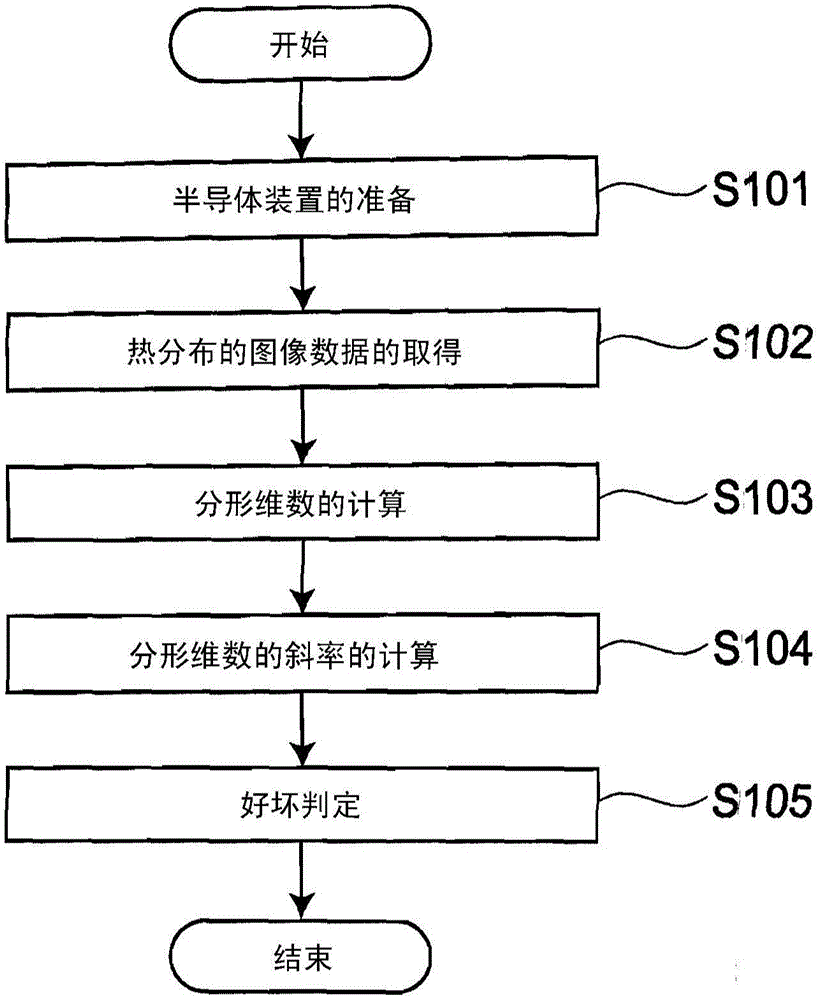

[0020] figure 1 It is a flowchart illustrating the inspection method of the semiconductor device according to the first embodiment.

[0021] Such as figure 1 As shown, this embodiment has the following steps: preparation of semiconductor device (step S101), acquisition of image data of thermal distribution (step S102), calculation of fractal dimension (step S103), calculation of slope of fractal dimension (step S104), and good or bad judgment (step S105).

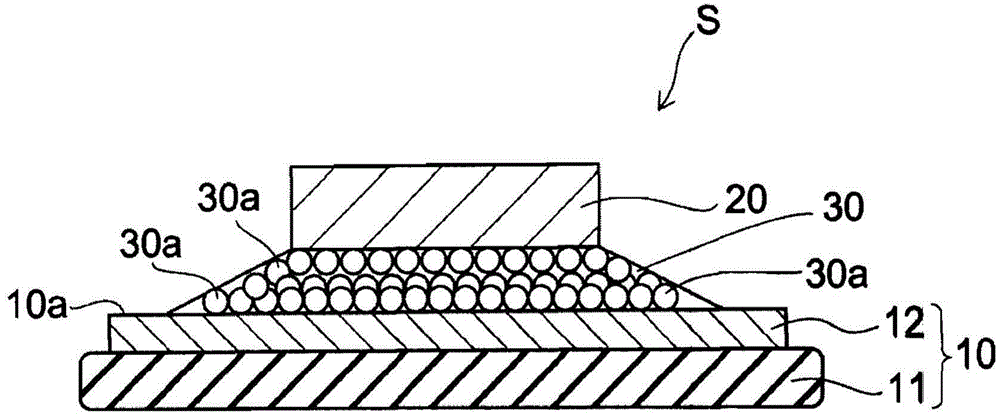

[0022] In the preparation of the semiconductor device shown in step S101 , a semiconductor device in which a semiconductor element and a substrate are bonded by a bonding material containing metal fine particles is prepared. A semiconductor device is an object to be judged whether the junction is good or bad.

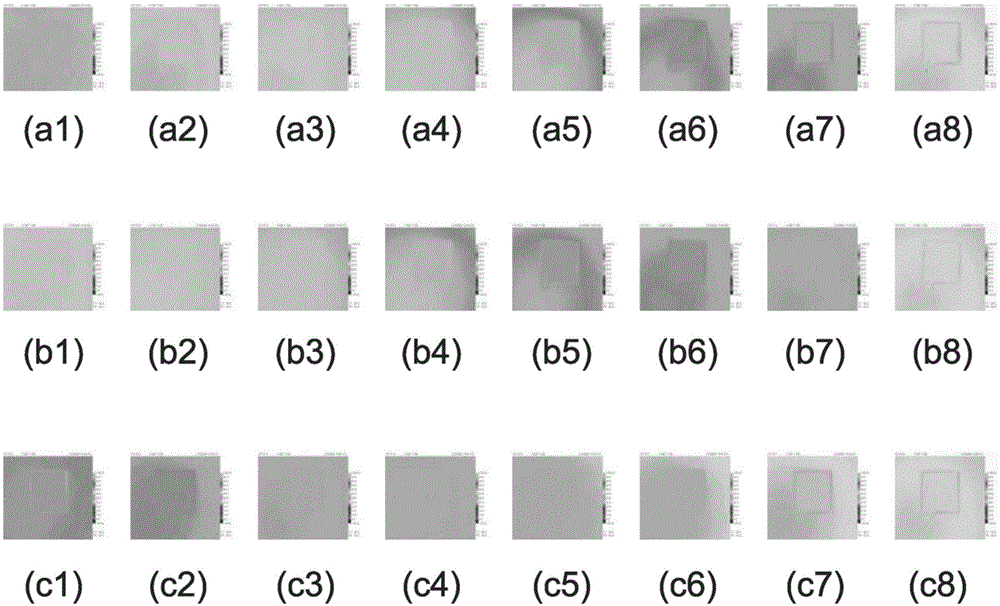

[0023] In acquiring the image data of the heat distribution shown in step S102 , the semiconductor device prepared in step S101 is heated, and the image data of the heat distribution in the semiconductor device is...

no. 2 approach )

[0080] Next, an inspection device for a semiconductor device according to a second embodiment will be described.

[0081] Figure 9 It is a figure which exemplifies the inspection apparatus of the semiconductor device of 2nd Embodiment.

[0082] Such as Figure 9 As shown, the semiconductor device inspection device 210 of this embodiment includes a heating unit 201 , an image acquisition unit 202 , and a determination unit 203 . The inspection device 210 is a device that implements the semiconductor device inspection method of the first embodiment described above.

[0083] The heating unit 201 has a heat source for heating the semiconductor device S (for example, a high-frequency oscillator, a lamp). It is desirable that the heat source has a structure capable of intensively heating the semiconductor device S. For example, it is desirable that the range of the heat source is approximately equal to the size of the semiconductor device S. FIG. By intensively heating the sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com