Board inspection apparatus

A substrate inspection and substrate technology, which is applied to measurement devices, optical devices, televisions, etc., can solve problems such as leakage and reduce inspection accuracy, and achieve the effect of realizing high speed, improving inspection accuracy, and realizing inspection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

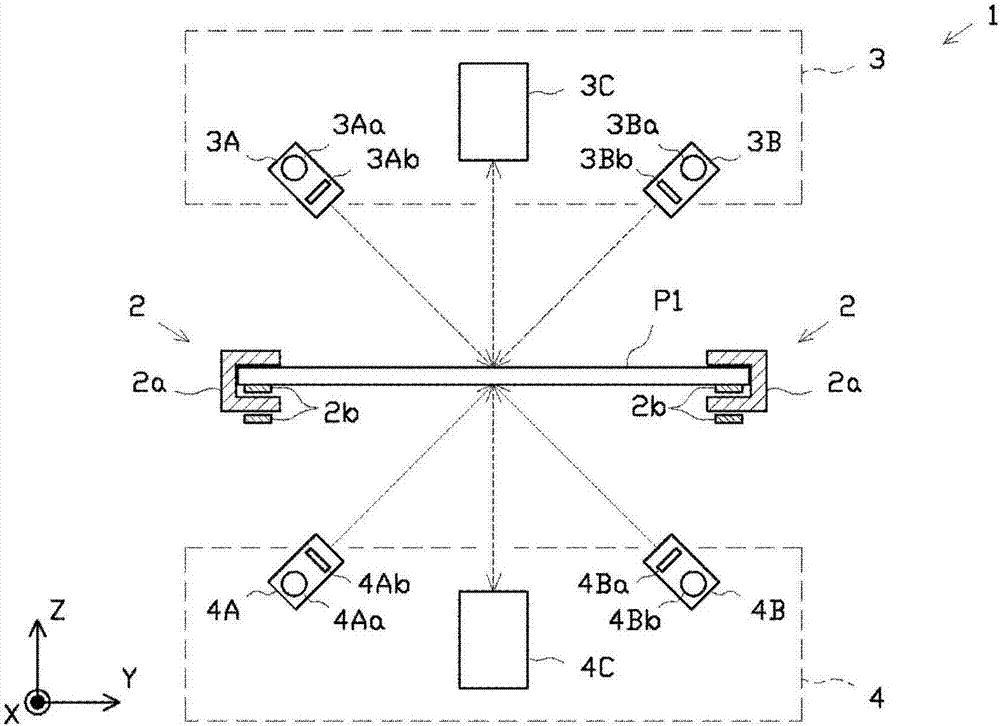

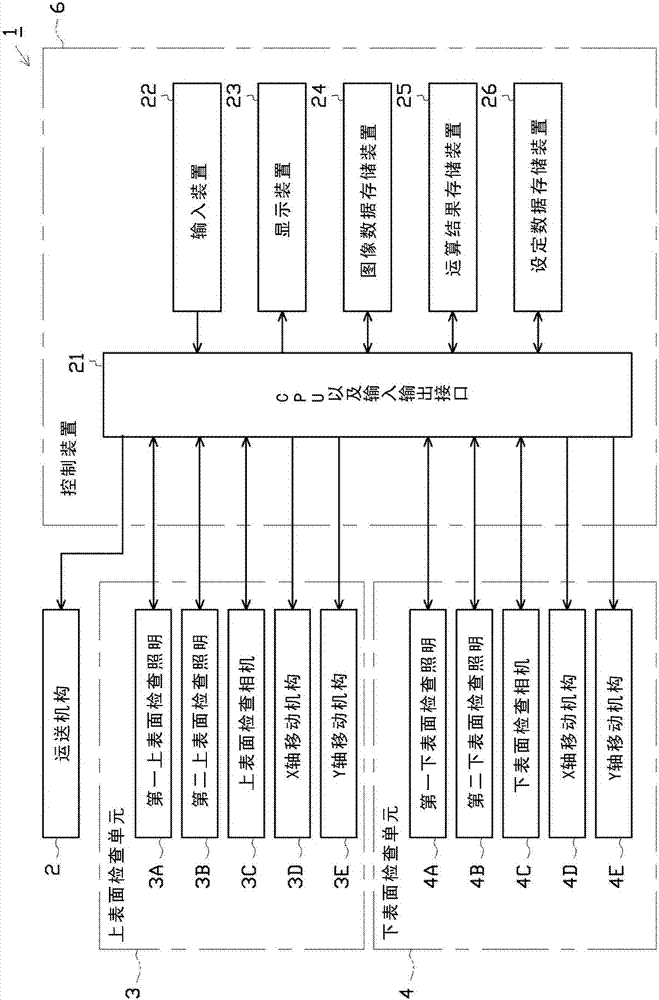

[0070] Hereinafter, one embodiment will be described with reference to the drawings. First, the configuration of a printed circuit board to be inspected will be described in detail. In the present embodiment, a two-layer substrate (double-sided substrate) on which electronic components are mounted on both the front and rear surfaces is used as an inspection object.

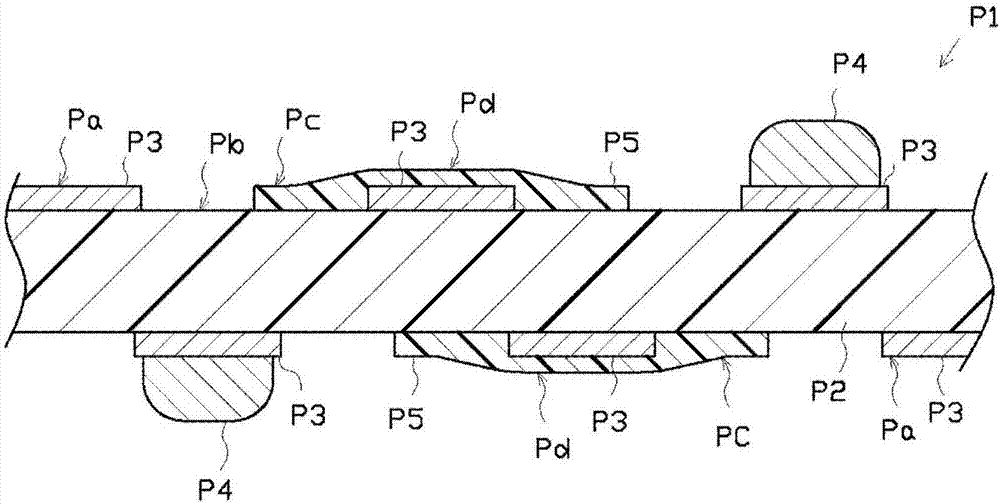

[0071] Such as figure 2 As shown, the printed board P1 has a flat plate shape, and electrode patterns P3 made of copper foil are provided on both front and back surfaces of a base board P2 made of glass epoxy resin or the like. Furthermore, the solder paste P4 which is a measurement object is printed and formed in the predetermined position (bonding land or pad, etc.) of the electrode pattern P3. The region where this solder paste P4 is printed is called "solder printing region". The parts other than the solder printing area are collectively referred to as "background area". The area of the etching film P5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com