A flat thin film capacitor core rubber wrapping device

A technology of thin film capacitors and capacitor cores, which is applied in capacitors, capacitor manufacturing, circuits, etc., can solve problems that affect the product qualification rate, uneven end faces, and high failure rates, so as to improve the efficiency of encapsulation, overcome uneven end faces, and lower prices. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

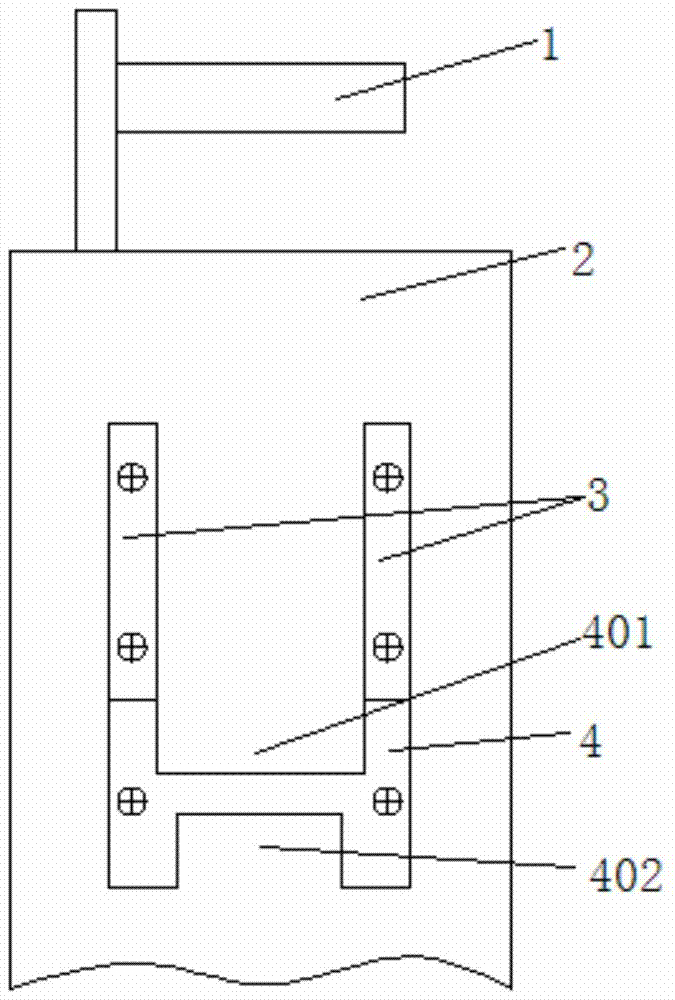

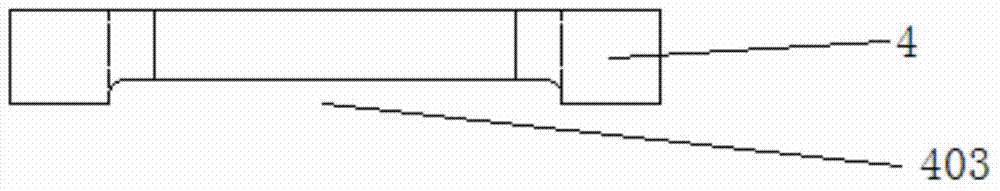

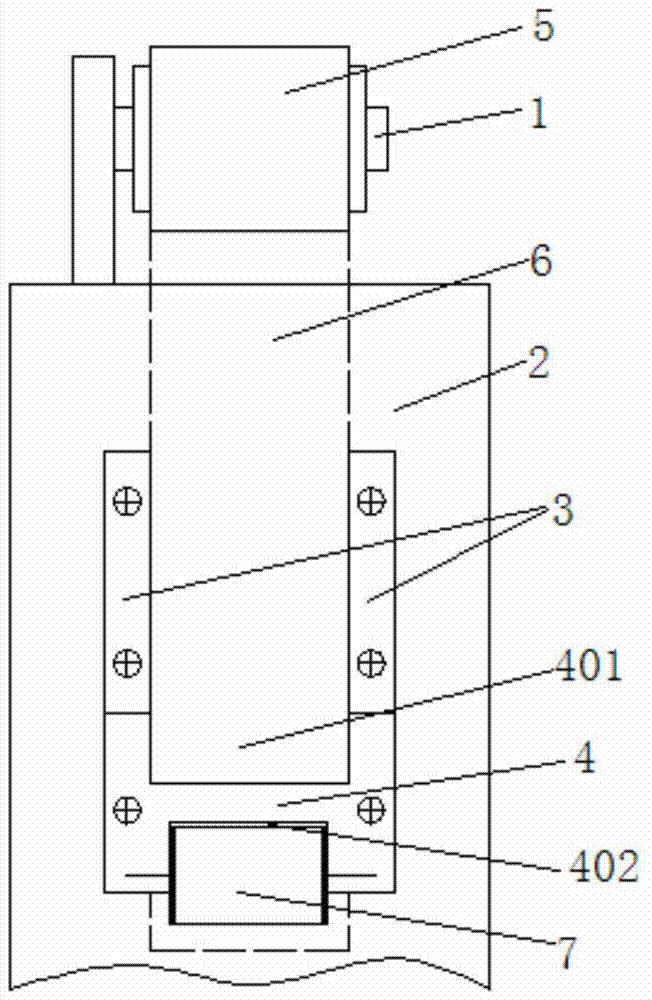

[0015] Referring to the accompanying drawings, a flat thin film capacitor core rubber encapsulation device includes a tape unwinding arm 1, a work surface 2, a tape guide block 3 and a capacitor core positioning block 4, and the tape unwind arm 1 is fixed on the work surface 2. On the upper side, the tape guide block 3 and the capacitor core positioning block 4 are all fixed on the work surface 2. There are two tape guide blocks 3, and the two tape guide blocks are arranged symmetrically. The two tape guide blocks 3 The distance between them is greater than 2mm of the width of the Mylar tape, and the height of the tape guide block is 3mm. The capacitor core positioning block 4 is arranged behind the tape guide block 3 and is close to the tape guide block 3, and the capacitor core positioning block 4 is close to the tape guide block 3. One side of the adhesive tape guide block 3 is provided with a first groove 401 with a distance greater than 2 mm of the width of the Mylar tape,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com