An encoder disassembly tool

An encoder and tool technology, applied in manufacturing tools, hand-held tools, etc., can solve problems such as difficulty in disassembling the rear end cover, fragile glass code disc for engraving, scrapping of encoder, etc., and achieve considerable economic value and application promotion value. , The operation mode is simple and easy, and the effect of smooth and smooth disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

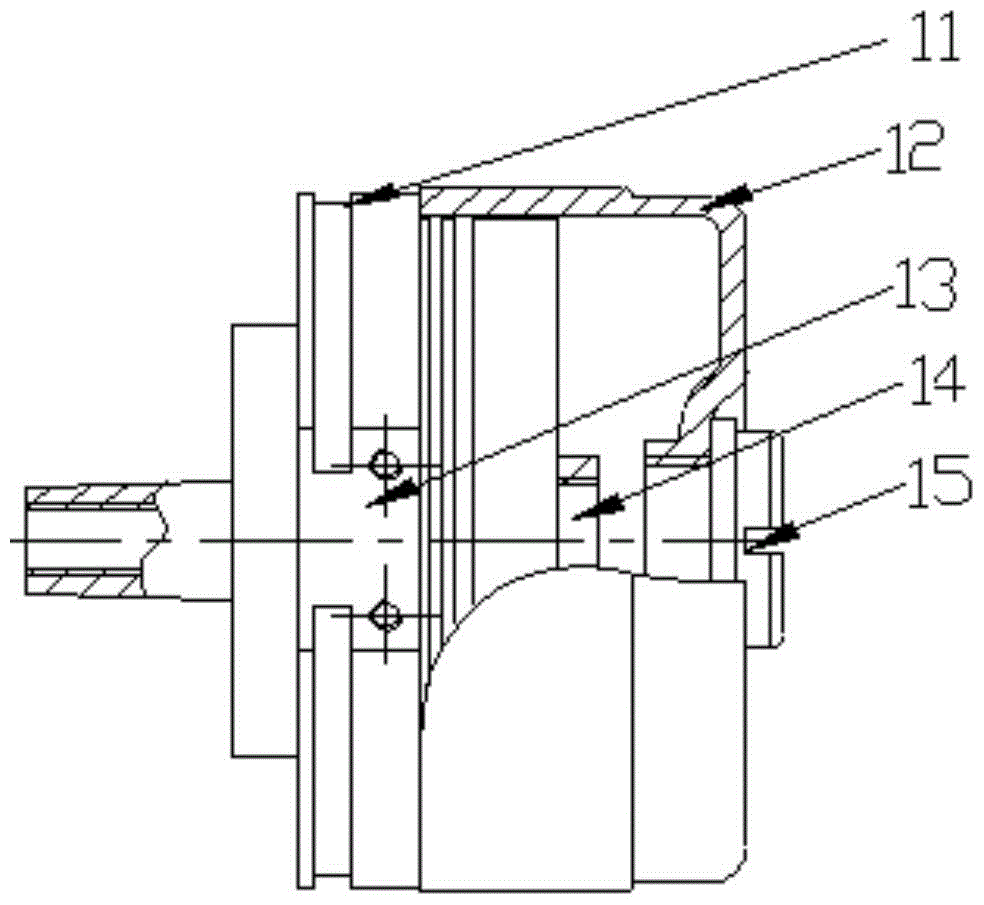

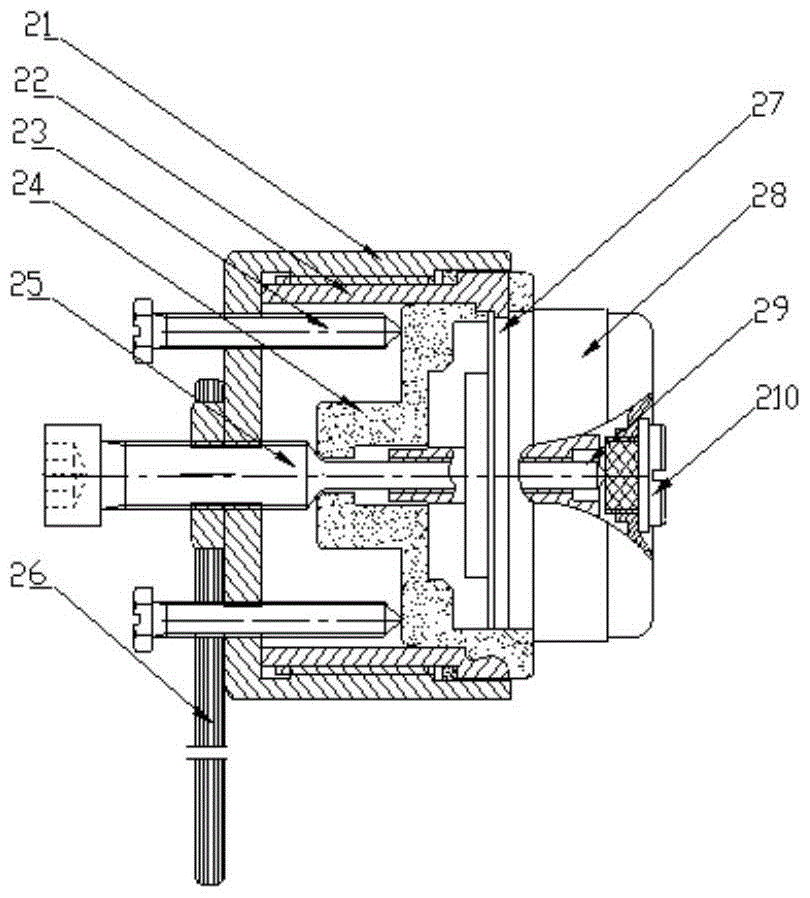

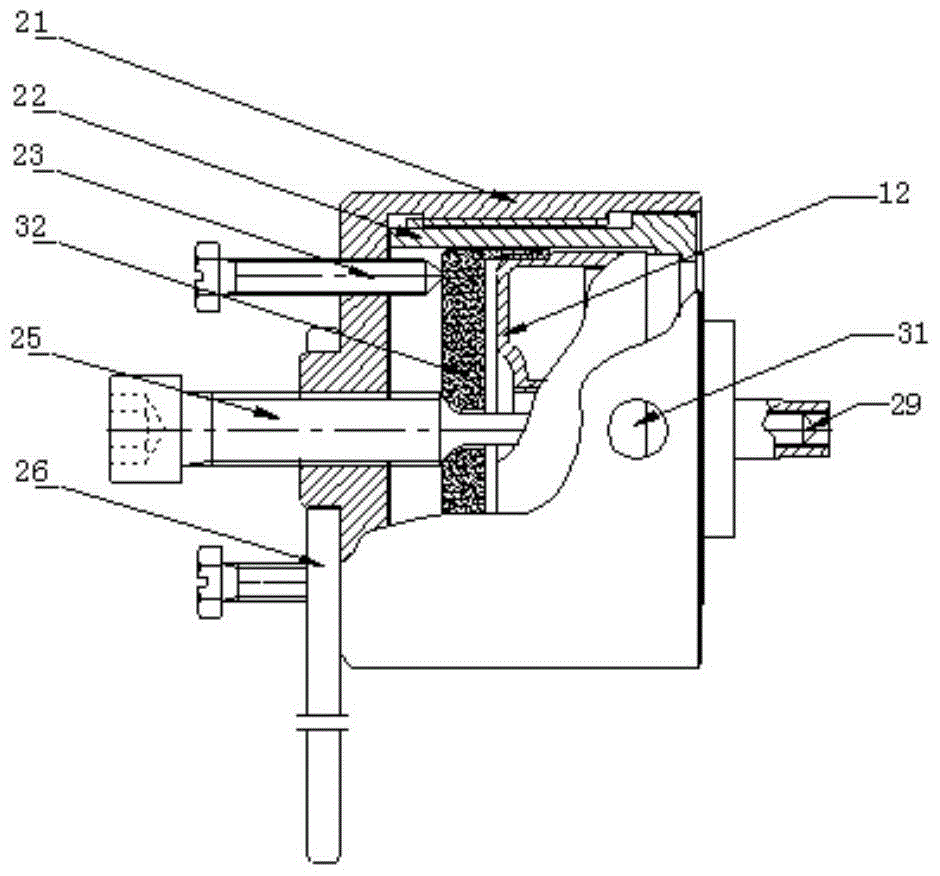

[0024] As shown in the figure, an encoder disassembly tool provided by the present invention includes a combination of two semi-cylindrical claw sleeves and an outer sleeve matching the external thread that are sleeved on the annular groove 11 of the encoder. The front edge of the claw cylinder 21 matches the encoder annular groove; one side of the outer sleeve 21 is provided with an auxiliary screw 23; one end of the auxiliary screw is connected to the outer sleeve through the rotation of the auxiliary screw. Function; the other side of the outer sleeve is connected with the annular groove.

[0025] The outer sleeve is also provided with a jack bolt 25 and a back cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com