An intelligent dismantling method for waste power batteries

A power battery, intelligent technology, applied in the field of intelligent dismantling of waste power batteries, to achieve high dismantling capacity and improve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

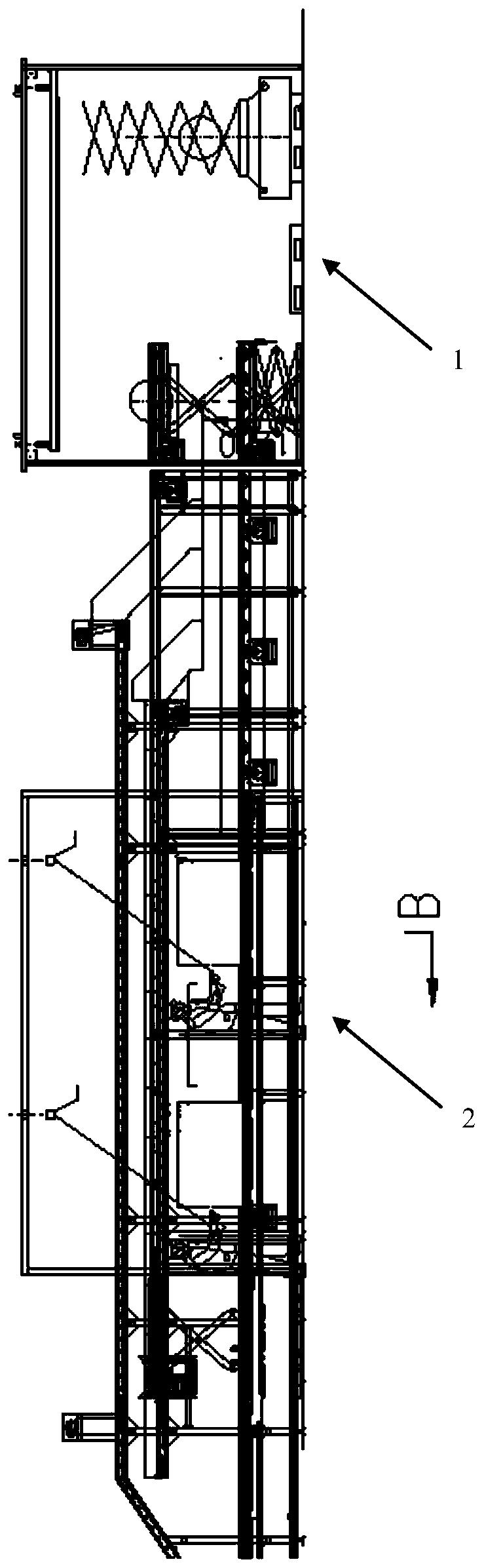

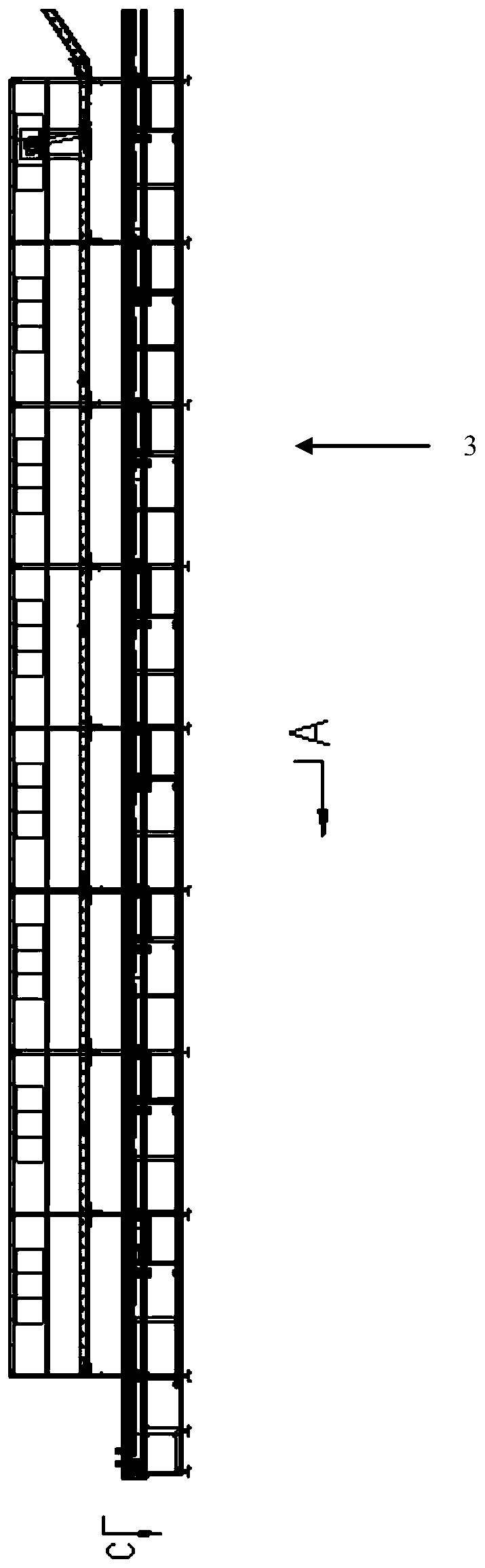

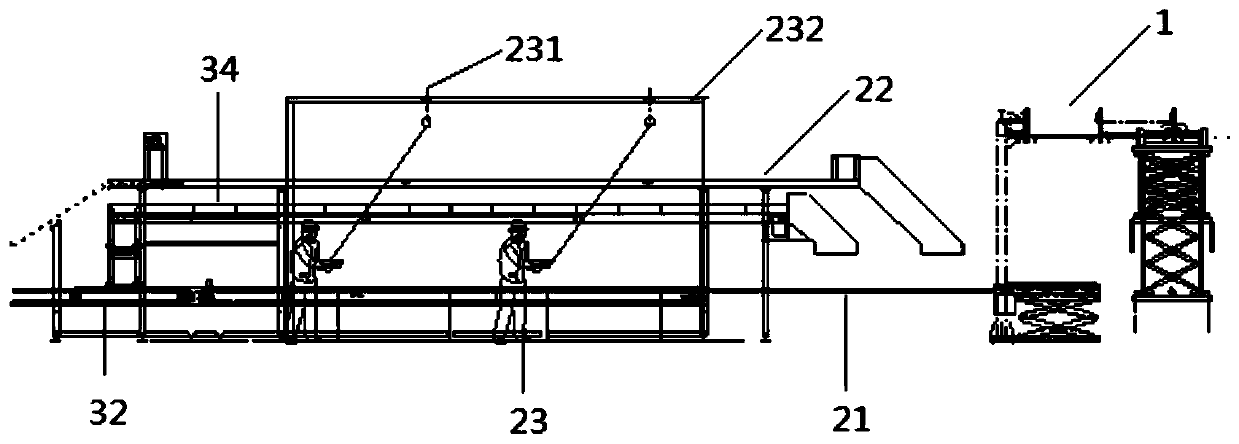

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0024] The first object of the present invention is to provide an intelligent dismantling method for waste power batteries, including: dismantling the battery pack into a module and a bottom case, and then disassembling the module into a cell, an insulating plate, and a pole plate and the modular plastic box, returning the bottom case along the conveying direction of the battery pack.

[0025] In order to make the entire waste power battery intelligent dismantling system more continuous, the return rate of the bottom case is preferably not lower than the delivery rate of the battery pack.

[0026] More preferably the dismantling is carried out using the system proposed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com