A middle and later production method of double horizontal well sagd in heavy oil reservoir

A production method and horizontal well technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems affecting the effective production of oil layers, large flow resistance, poor economic benefits, etc., and achieve the improvement of crude oil fluidity and Oil recovery rate, accelerated viscosity reduction of crude oil, and high viscosity reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

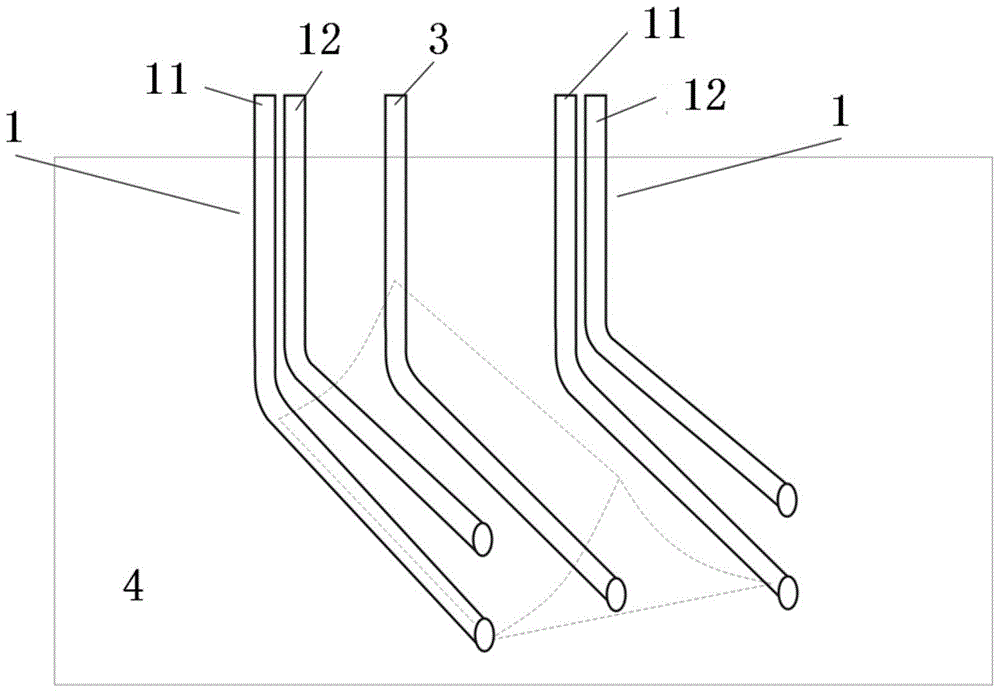

[0040] This embodiment provides a SAGD mid-late production method for dual horizontal wells in heavy oil reservoirs, the well location distribution of which is as follows figure 1As shown, the heavy oil reservoir is developed by double-horizontal well SAGD, and the well spacing of the adjacent double-horizontal SAGD well pair 1 is 100 meters. It has entered the middle stage of SAGD development and the production has begun to decline. Include the following steps:

[0041] Step 1: Deploy a horizontal well 3 in the middle of the existing two adjacent dual-horizontal SAGD well pairs 1, the horizontal section of the horizontal well 3 is parallel to the horizontal section of the adjacent dual-horizontal SAGD well pair 1, and is located in the oil reservoir 4 2m above the bottom boundary;

[0042] Step 2: After the steam chambers of two adjacent double-horizontal SAGD well pairs 1 expand to merge with each other, inject thermal fluid into the newly deployed horizontal well 3 for huf...

Embodiment 2

[0050] This example provides a mid-to-late production method of dual-horizontal well SAGD for a heavy oil reservoir. The heavy-oil reservoir is developed by using dual-horizontal well SAGD. The well spacing of adjacent dual-horizontal SAGD well pairs is 90 meters, and has entered SAGD. In the middle stage of development, the production of heavy oil reservoirs begins to decline, the above method specifically includes the following steps:

[0051] Step 1: Deploy a horizontal well in the middle of two existing adjacent dual-horizontal SAGD well pairs. The horizontal section of the horizontal well is parallel to the horizontal section of the adjacent dual-horizontal SAGD well pairs, and is located 2m above the bottom of the reservoir ;

[0052] Step 2: After the steam chambers of two adjacent double-horizontal SAGD well pairs are expanded to merge with each other, inject thermal fluid into the newly deployed horizontal wells for huff and puff production;

[0053] Among them, the ...

Embodiment 3

[0060] This example provides a mid-to-late production method of double-horizontal well SAGD for a heavy oil reservoir. The heavy-oil reservoir is developed by using double-horizontal well SAGD. The well spacing of adjacent double-horizontal SAGD well pairs is 110 meters, and has entered SAGD. In the middle stage of development, the production of heavy oil reservoirs begins to decline, the above method specifically includes the following steps:

[0061] Step 1: Deploy a horizontal well in the middle of two existing adjacent dual-horizontal SAGD well pairs. The horizontal section of the horizontal well is parallel to the horizontal section of the adjacent dual-horizontal SAGD well pairs, and is located 2m above the bottom of the reservoir ;

[0062] Step 2: After the steam chambers of two adjacent double-horizontal SAGD well pairs are expanded to merge with each other, inject thermal fluid into the newly deployed horizontal wells for huff and puff production;

[0063] Wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com