Intelligent RTP (reinforcing thermal pipe) tube and production method thereof

An intelligent, external tube technology, applied in the direction of hoses, pipes, pipeline systems, etc., can solve the problems of high false alarm rate, inability to achieve long-distance pipeline coverage, untimely forecasting, etc., and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

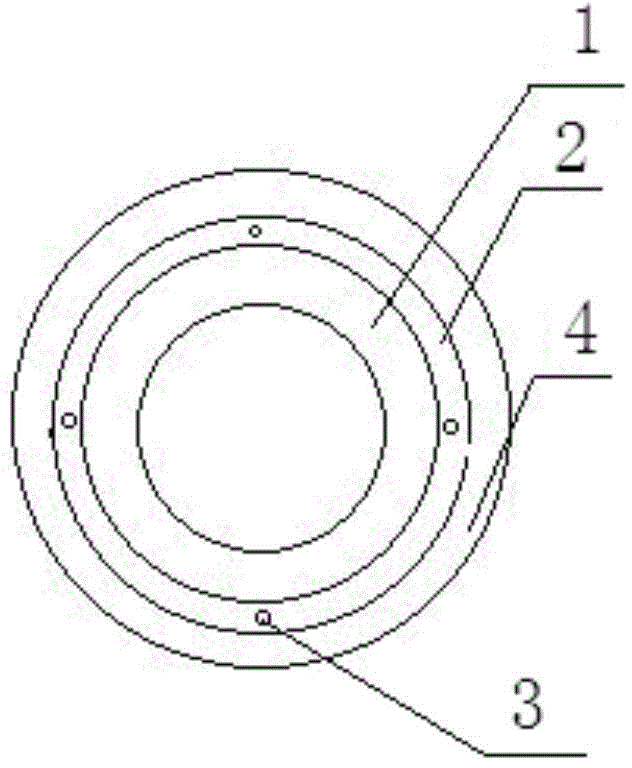

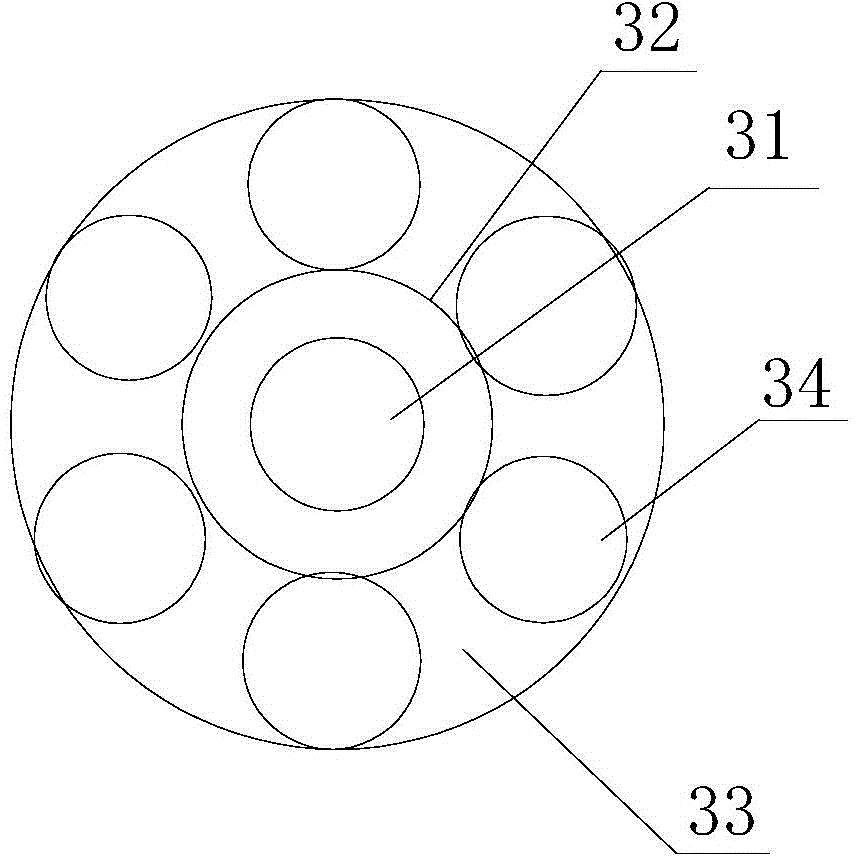

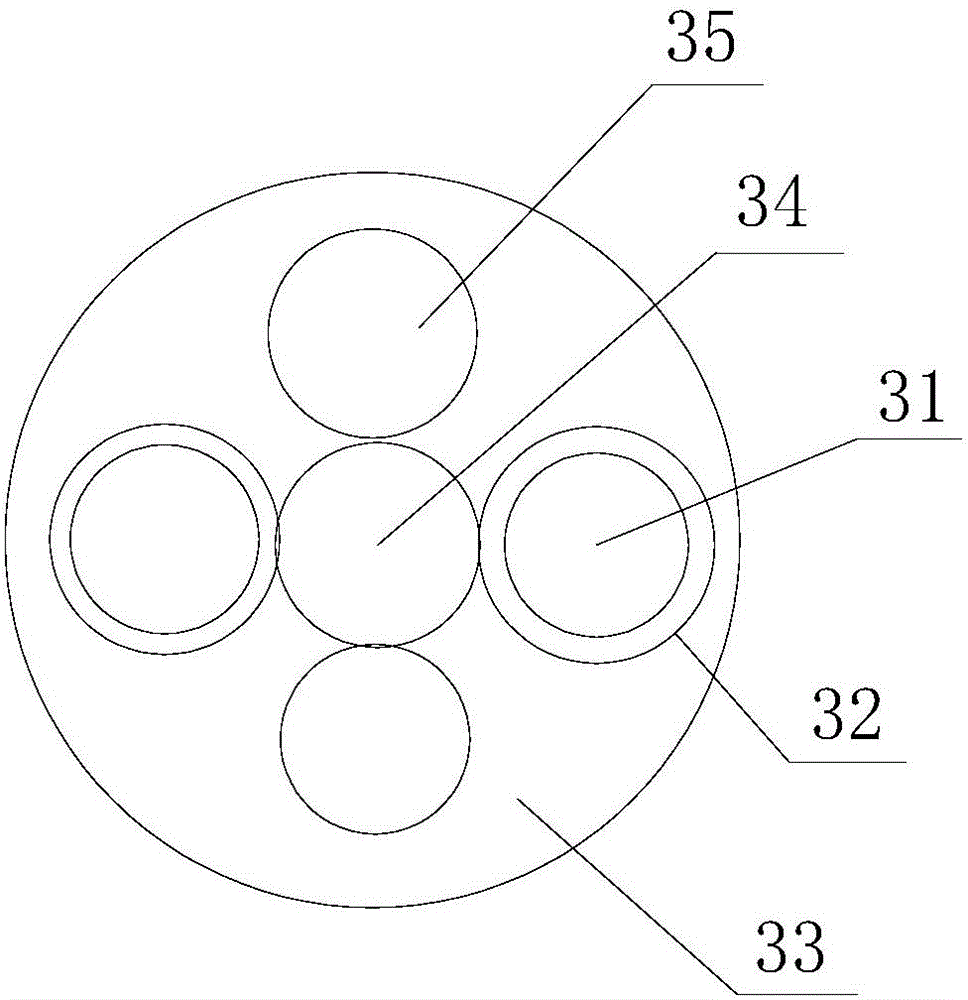

[0037] The intelligent RTP pipe of this embodiment has a structure such as figure 1 As shown, it includes an inner tube 1 and an outer tube 4. An enhanced sensing layer is provided between the inner tube 1 and the outer tube 4. The enhanced sensing layer is composed of a composite tape wound on the outer wall of the inner tube 1 at a predetermined winding angle. The winding angle is 50-60°. The composite tape includes a group of pretensioned reinforcing fibers 2 that are evenly distributed side by side along the axial direction of the inner tube, and several sensing optical cables 3 are uniformly distributed in the reinforcing fibers 2, and the sensing optical cables 3 are arranged adjacent to the reinforcing fibers 2, and the sensing optical cables The length of 3 is greater than that of the reinforcing fiber 2, so that the end of the composite tape has a sensing optical cable 3 extending outward. The pretensioning stress of the reinforcing fiber 2 is 100±20 Newton, the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com