A method for detecting cable damage

A detection method and cable technology, applied in the direction of detecting faults and fault locations according to conductor types, can solve the problems of manpower and material resources, waste of resources, covering cables and cables, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

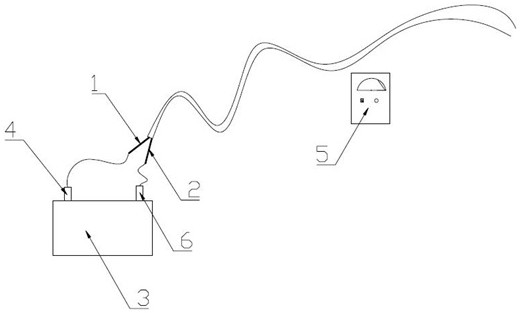

[0042] Example: such as figure 1 Shown, a kind of detection method of cable breakage, comprises the following steps:

[0043] S1. Confirm the cause of cable damage,

[0044] S1.1. Determine whether there is a short circuit between A core wire 1 and B core wire 2, use a multimeter to measure the internal resistance between A core wire 1 and B core wire 2, if there is a short circuit between A core wire 1 and B core wire 2 The internal resistance is not less than 1MΩ, indicating that there is no short circuit between A core wire 1 and B core wire 2, then enter S1.2, if the internal resistance between A core wire 1 and B core wire 2 is less than 1MΩ, it means A core If a short circuit occurs between wire 1 and B core wire 2, enter S2;

[0045] S1.2. To determine whether there is a short circuit between the core wire and the shield, use a multimeter to measure the internal resistance between the A core wire and the B core wire and the shield, if the internal resistance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com