Steel for saw blade and its production method

A production method and saw blade technology, applied in the field of metal materials, can solve problems such as difficult production, and achieve the effects of simple production method, reasonable component control and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

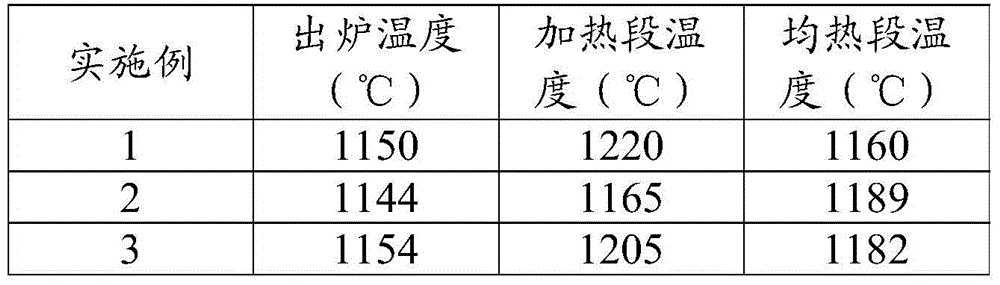

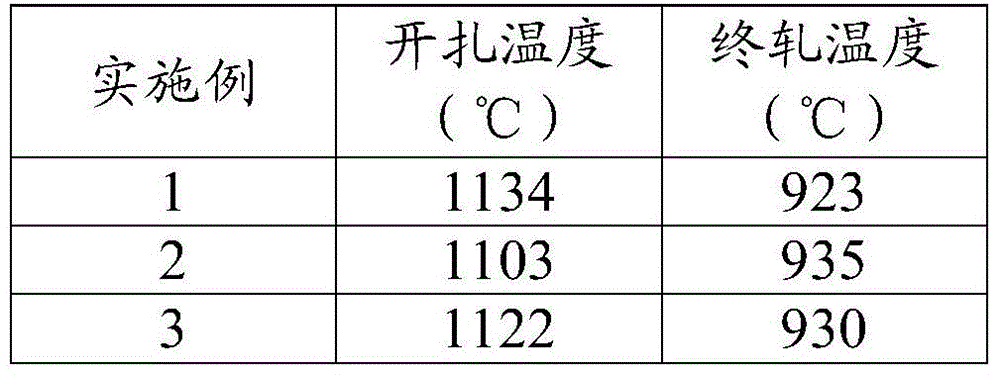

[0020] The concrete flow process of the production method of saw blade steel of the present invention is as follows:

[0021] Step S1: converter smelting;

[0022] In order to ensure the quality of steel for finished saw blades and the precise control of the components of the finished product, the following process parameters need to be strictly controlled: the mass percentage of P in the initial molten iron smelted by the converter ≤ 0.013%, and the mass percentage of S ≤ 0.050%. During the smelting process of converter smelting, 3700-5400kg of lime, 500-3000kg of dolomite, 0-150kg of fluorite and 500-2000kg of iron sheet are added to every 100 tons of molten iron. As shown in Table 1, it is the quality of the ingredients added in the converter smelting process of the embodiment of the present invention. The tapping temperature of molten steel at the end of converter smelting is 1605-1660°C, the average value is 1635°C, the mass percentage of C is 0.03%-0.13%, the average ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com