A kind of 3D printing rare earth magnesium alloy powder and preparation method thereof

A 3D printing, rare earth magnesium technology, applied in additive processing and other directions, can solve the problems of active chemical properties of magnesium alloys, high equipment requirements, and unfavorable research, and achieve ideal powder particle size distribution, low economic cost, and reasonable composition control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

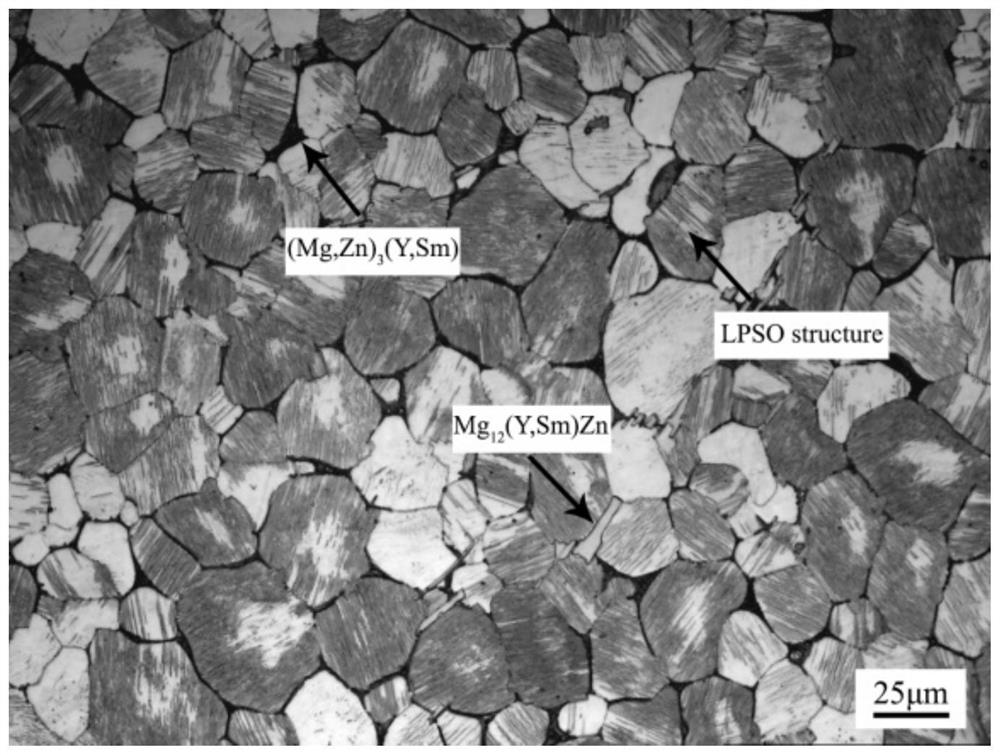

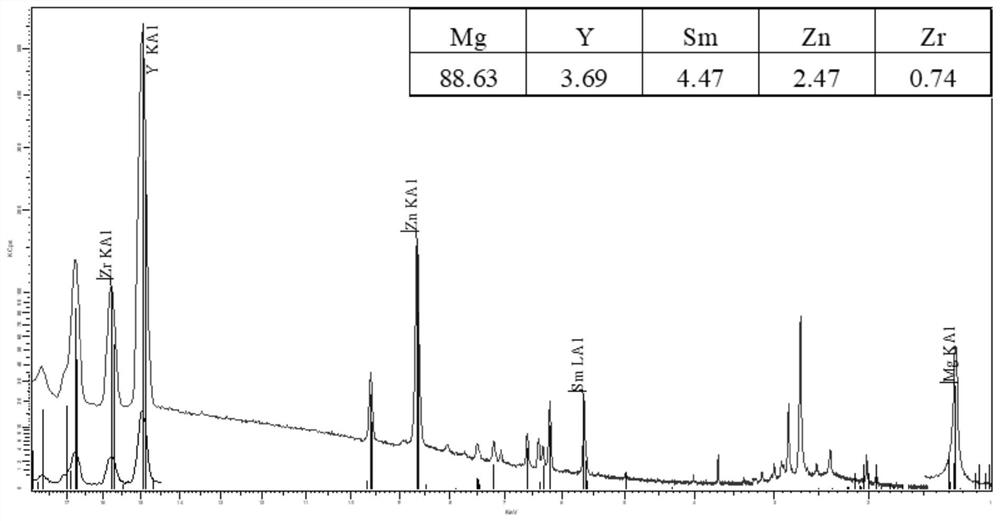

[0015] This example provides a kind of 3D printed rare earth magnesium alloy powder. The 3D printed rare earth magnesium alloy powder is composed of the following components by weight percentage: rare earth element Y: 3.69%, rare earth element Sm: 4.47%, Zn: 2.47%, Zr: 0.74%, the balance is magnesium and trace impurities, and the sum of the percentages of the components is 100%.

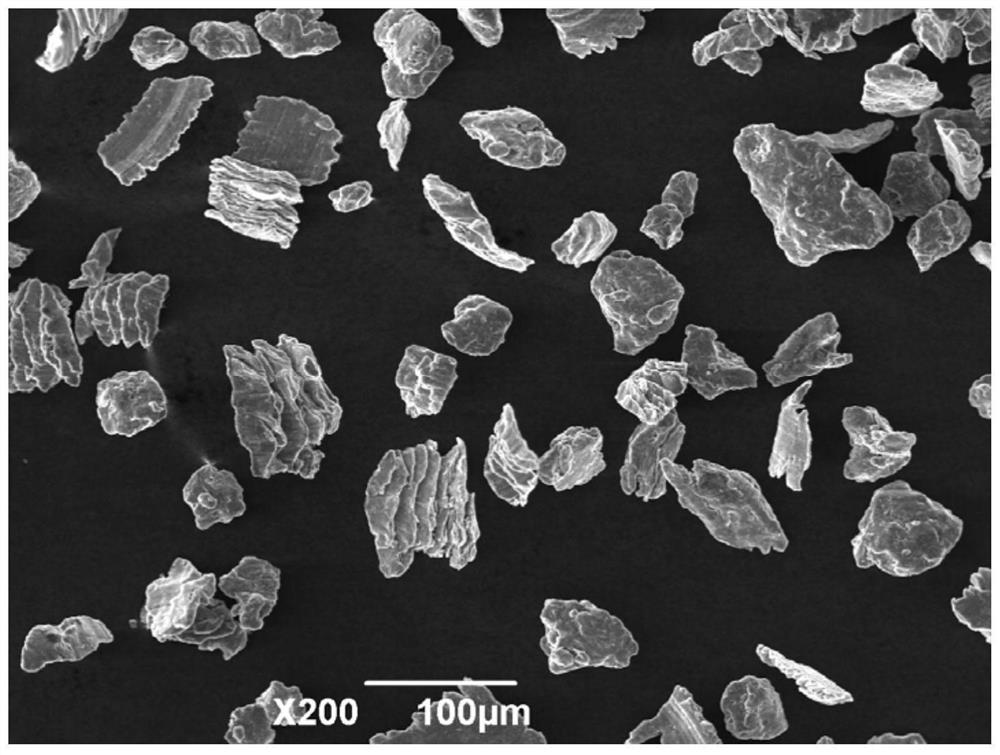

[0016] The preparation method of the above 3D printed rare earth magnesium alloy powder uses primary pure magnesium ingot, pure zinc, Mg-30wt% Y master alloy, Mg-30wt% Sm master alloy, Mg-30wt% Zr master alloy as raw materials, first With a well-type crucible resistance furnace, in CO 2 and SF 6 In a mixed protective atmosphere, the alloy rod body was obtained by melting and casting; then the alloy rod body was removed from the surface layer, polished with sandpaper for 20 minutes, and then the surface of the rod body was wiped with absolute ethanol to remove surface impurities; the processed alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com