Patents

Literature

30results about How to "Guaranteed compression ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

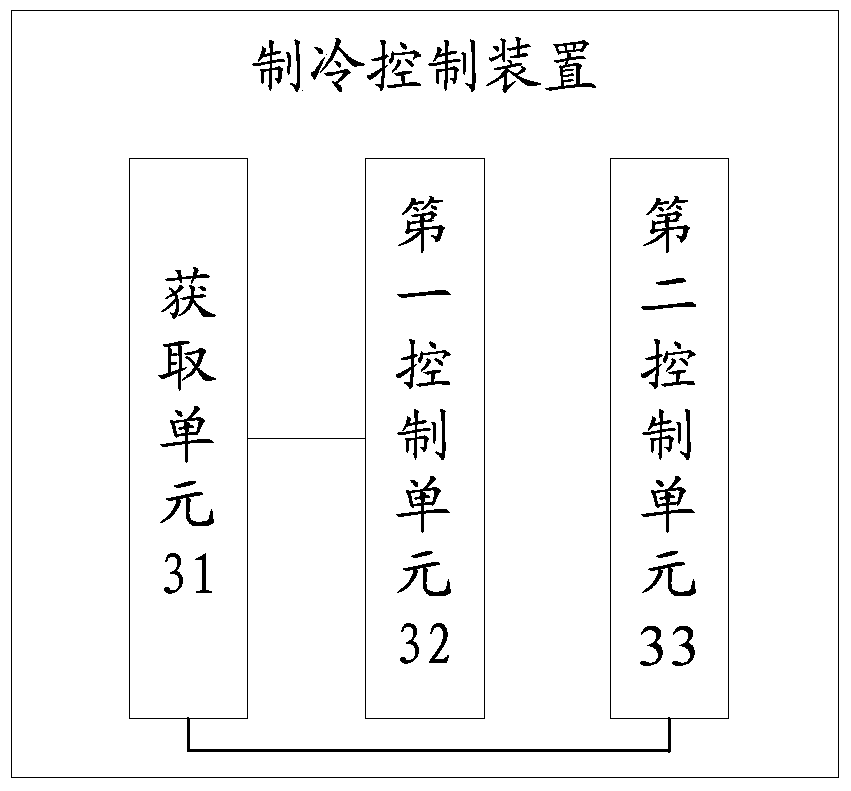

Refrigeration control method and device and air conditioner

ActiveCN105333563AIncreased likelihood of normal workGuaranteed compression ratioSpace heating and ventilation safety systemsLighting and heating apparatusFrequency intervalLower limit

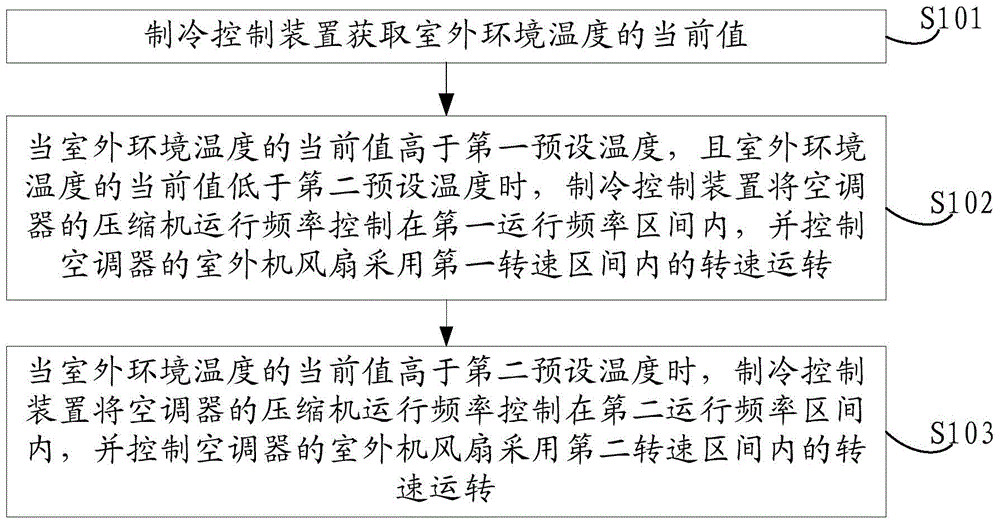

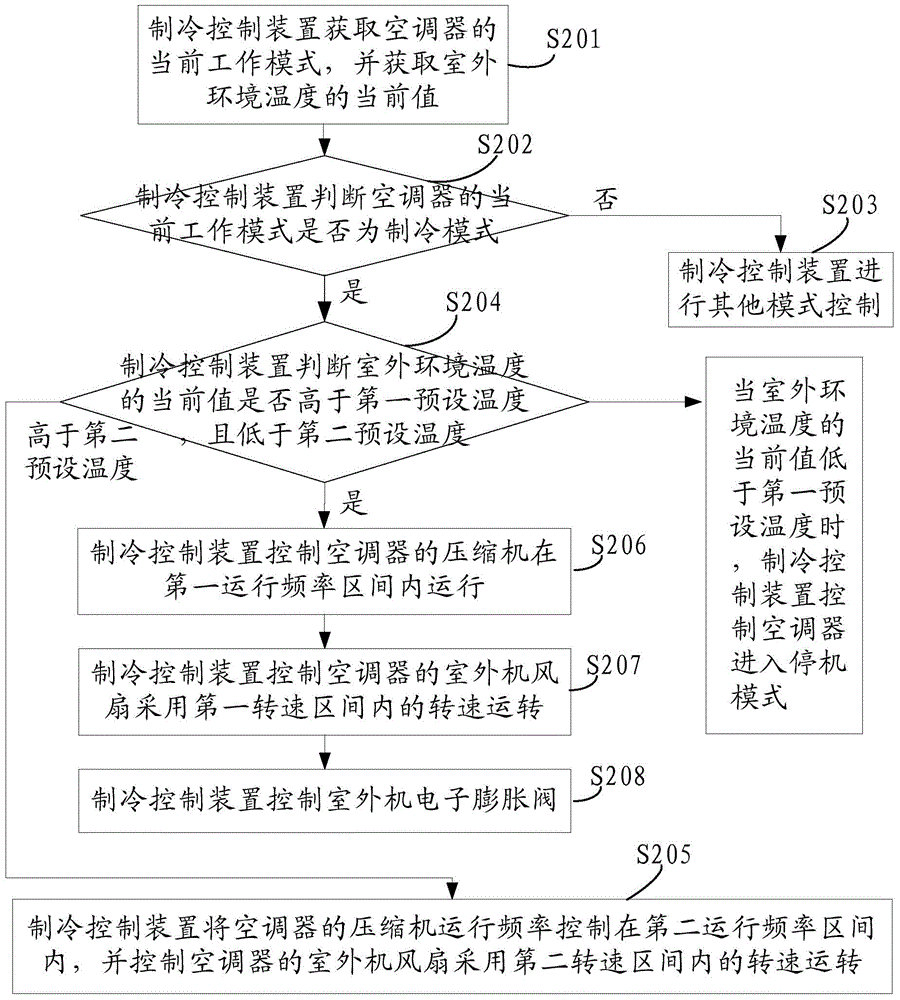

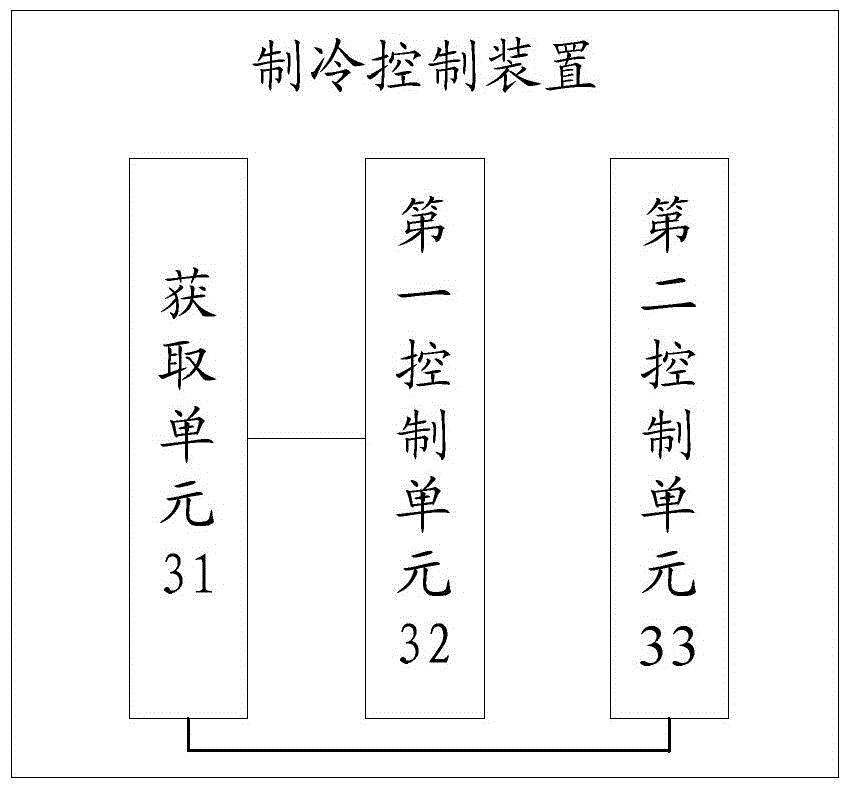

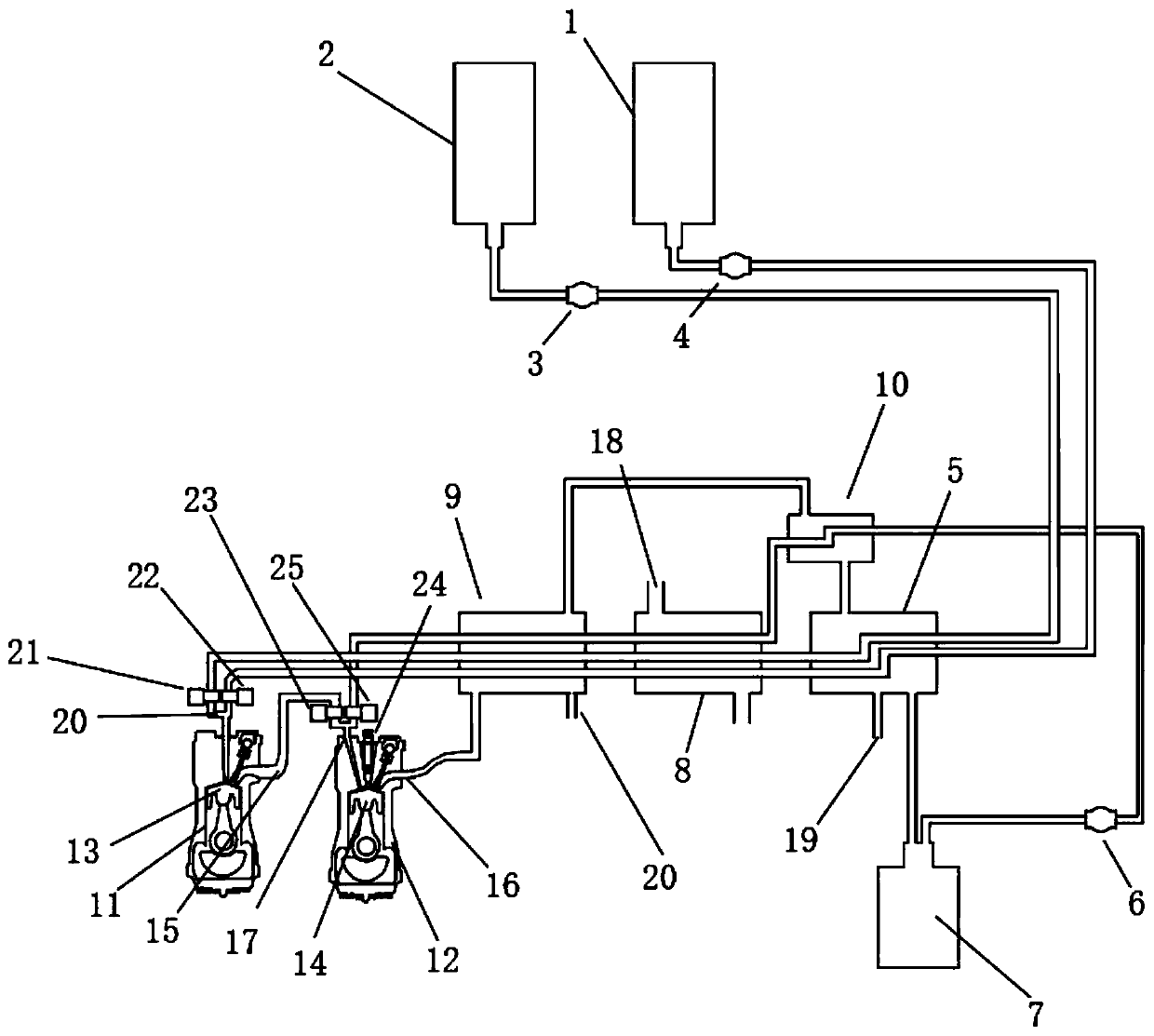

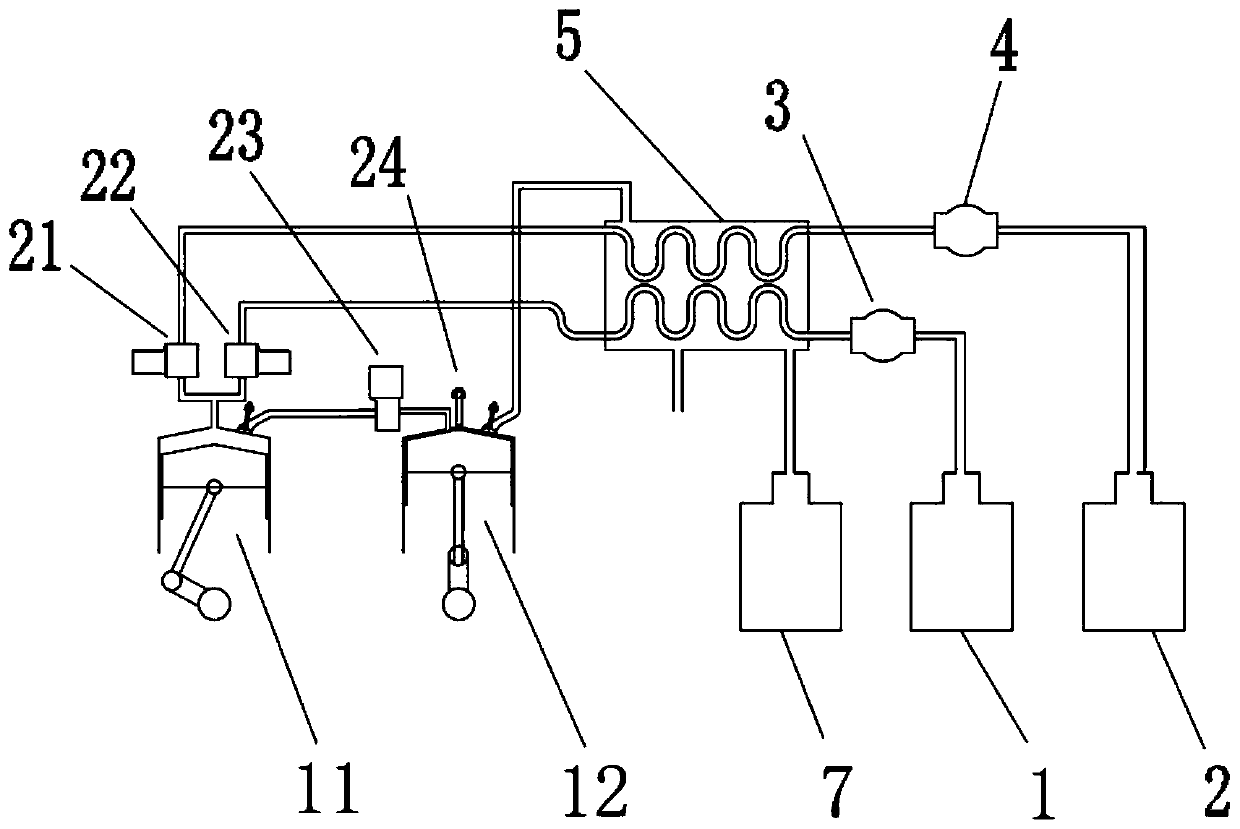

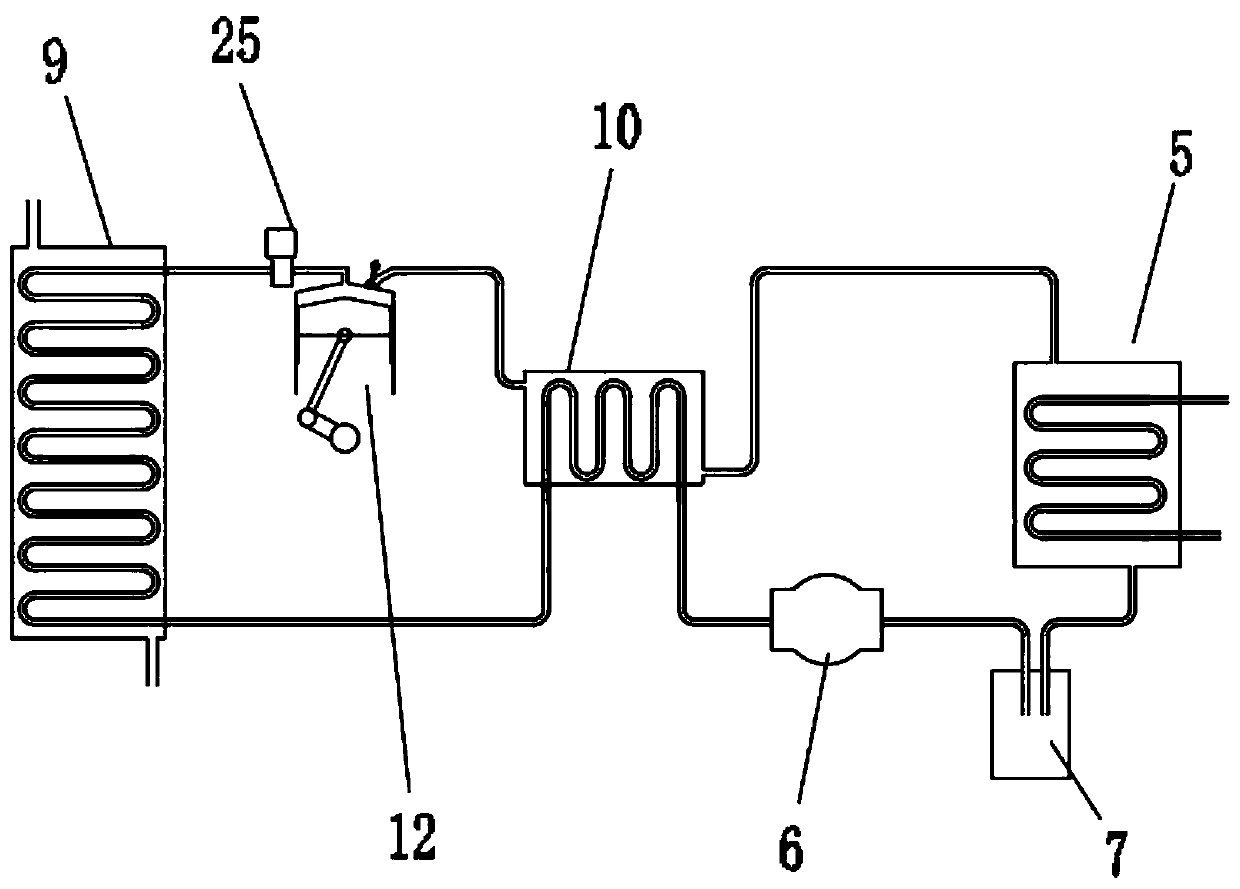

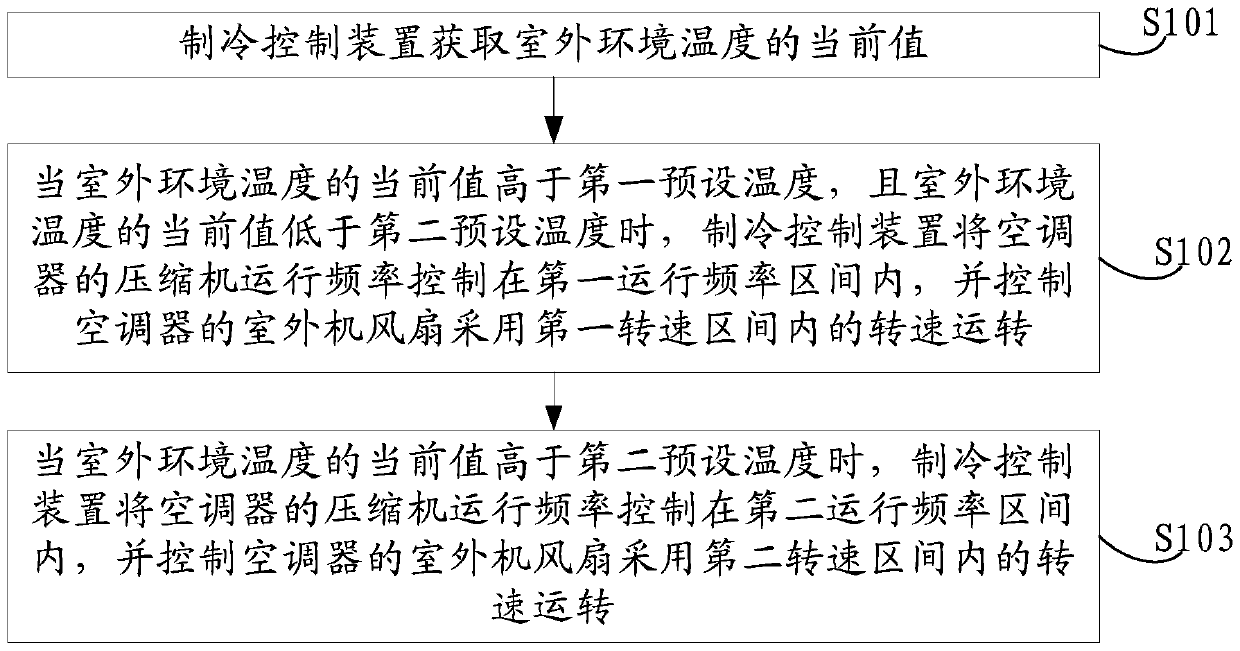

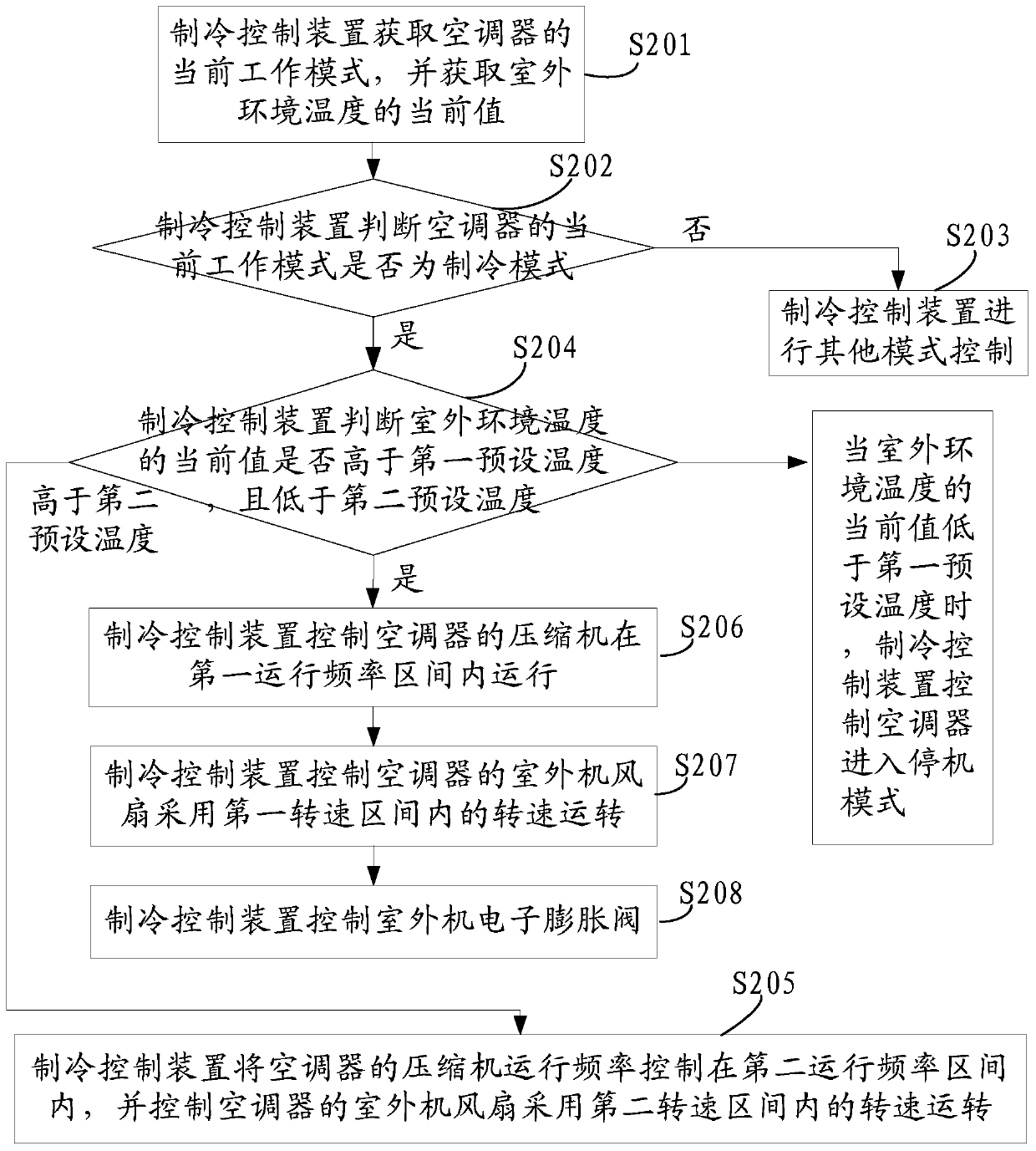

The embodiment of the invention discloses a refrigeration control method and device and an air conditioner and relates to the technical field of temperature control. It can be guaranteed that on the basis of reliability of the air conditioner, low-temperature refrigeration of the air conditioner is achieved. According to the specific scheme, the current value of the outdoor environment temperature is acquired, when the current value of the outdoor environment temperature is higher than a first preset temperature and lower than a second preset temperature, a compressor of the air conditioner is controlled to run under the frequency within a first running frequency interval, and an outdoor unit fan of the air conditioner is controlled to run at a rotating speed within a first rotating speed interval; and the frequency lower limit value of the first running frequency interval and the rotating speed upper limit value of the first rotating speed interval are running frequency of the compressor and the rotating speed of the outdoor unit fan respectively when the air conditioner performs refrigeration at the first preset temperature and the compression ratio of the compressor is at least the recommended compression ratio. The refrigeration control method and device are used in the temperature adjusting process of the air conditioner.

Owner:广东科龙嘉科电子有限公司

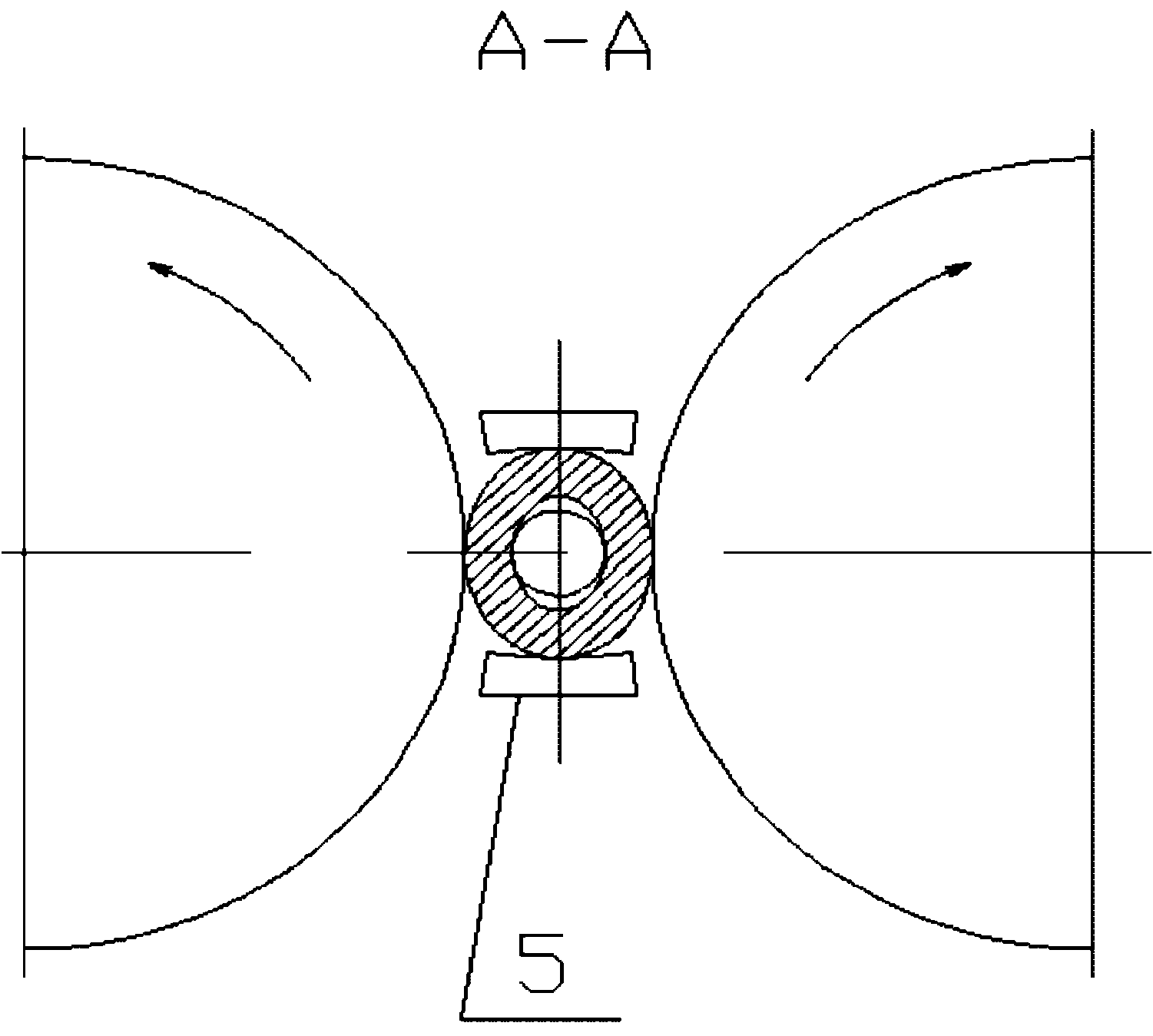

Pipe mold manufacturing process adopting continuous-casting blank to forge and roll rough blank periodically

InactiveCN102179681AHigh yieldLow costMetal rolling arrangementsStructure propertyEnergy consumption

The invention relates to a pipe mold manufacturing process adopting a continuous-casting blank to forge and roll a rough blank periodically, belonging to the technical field of pipe mold manufacture. The manufacturing process comprises the process steps of: smelting of the continuous casting blank in a blast furnace, reinspecting, blanking, heating in a ring-shaped furnace, mannesmann piercing, periodically rolling a pipe, straightening, detecting flaws with magnetic powder, cutting the head and the tail, roughly processing, boring, carrying out ultrasonic flaw detection, thermally treating, sampling and reinspecting, finish processing, carrying out surface strengthening treatment, inspecting, spraying and printing, weighing and warehousing. The pipe mold manufacturing process has the advantages that the continuous casting blank replaces the mold casting blank adopted by the existing process, the characteristics that the yield is high, the cost is low, the energy consumption is less, the structure property is stable and the like are fully exerted, and the cost is reduced in the two aspects of the process and raw materials; in addition, the forging and rolling of a Pilger type rolling machine and the structure characteristics of a classic T-shaped pipe mold are effectively combined, the condition that the pipe mold blank forged and rolled by the process periodically has the performance close to the forged blank of the traditional pipe mold is guaranteed, and the Pilger head which needs to be cut in rolling is fully utilized simultaneously, so that the production efficiency is improved greatly.

Owner:邯郸市鑫泽天然气科技有限公司

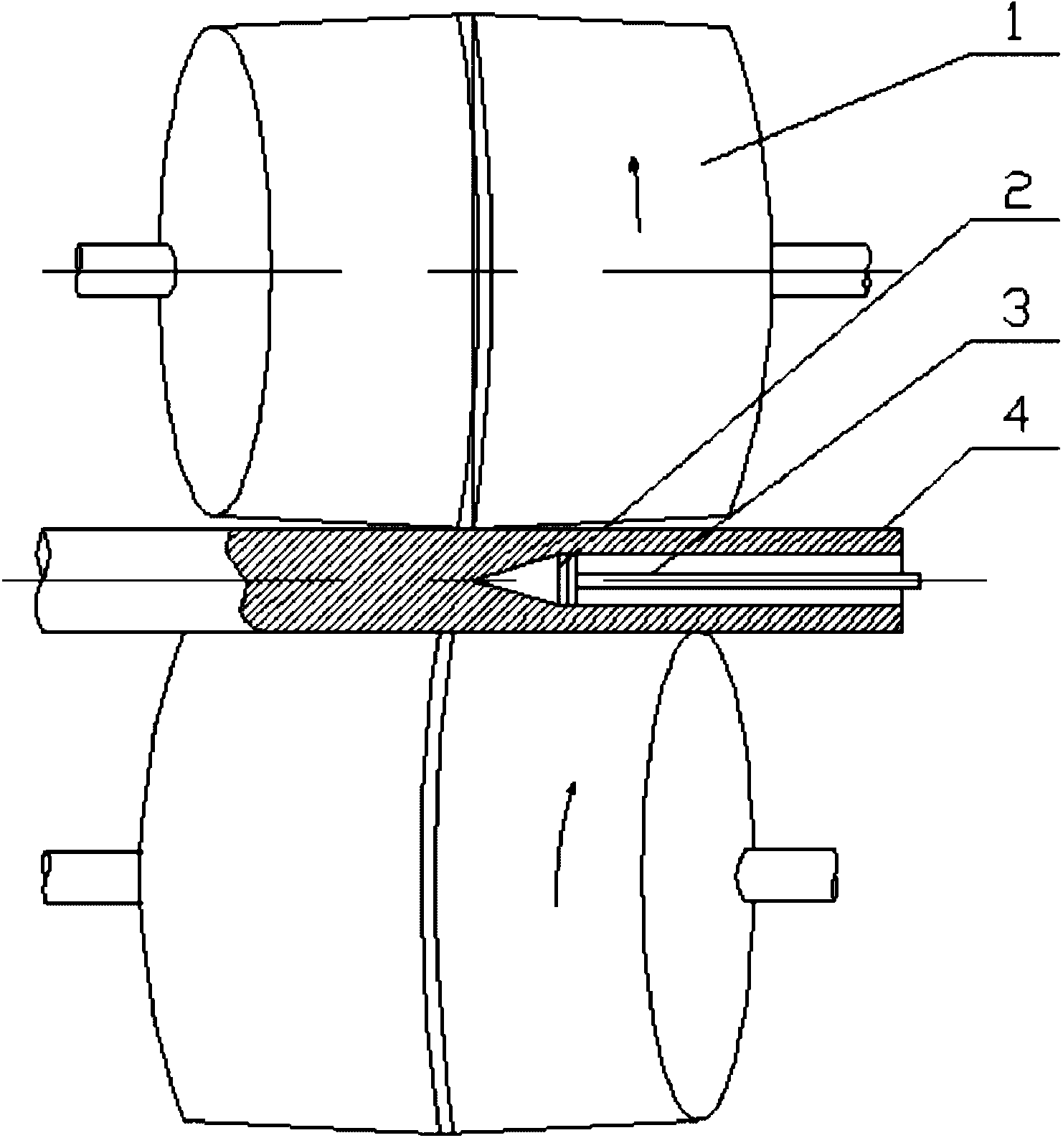

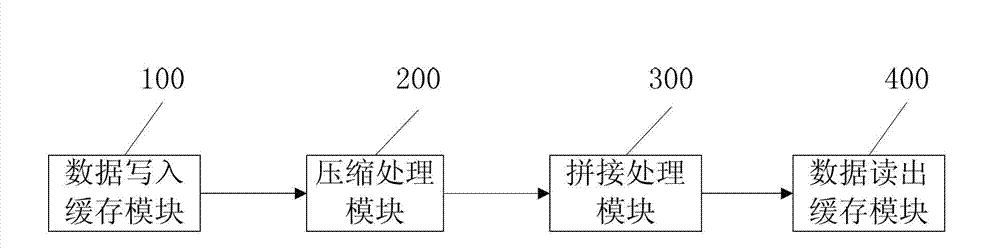

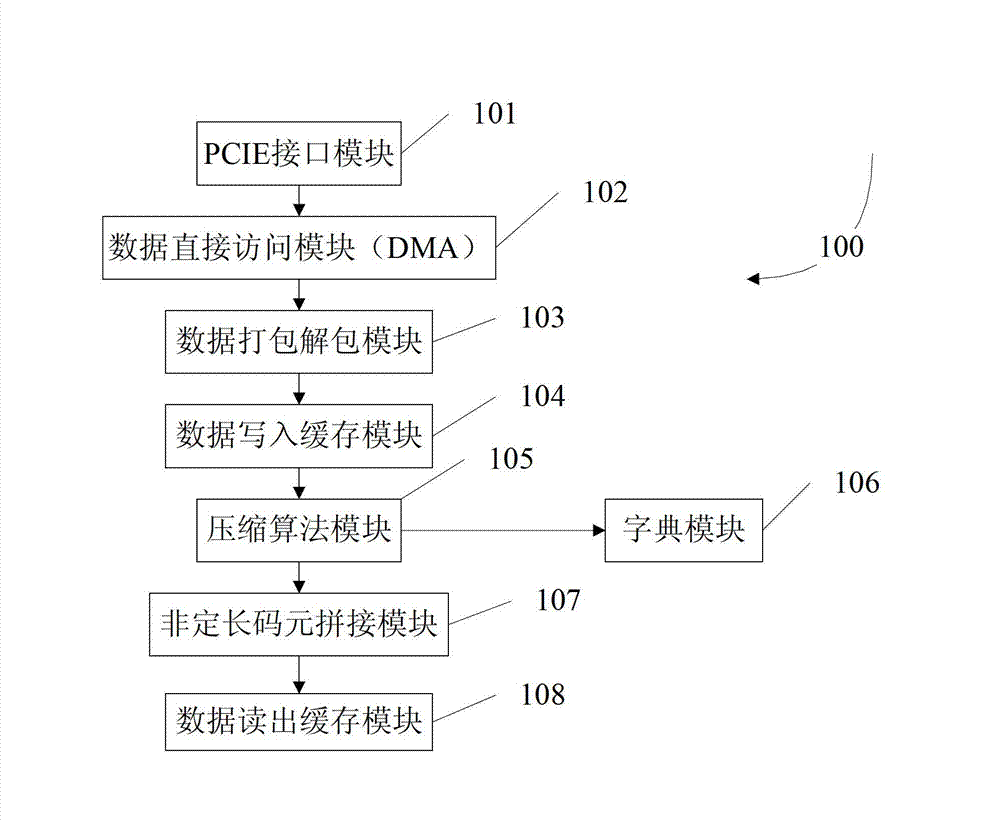

System and method for hardware LZ77 compression implementation

InactiveCN103095305AImprove compression efficiencyGuaranteed compression ratioCode conversionProcess efficiencyHash table

The invention provides a system and a method for hardware LZ77 compression implementation. The method comprises the following steps: step 1 caching data to be compressed, step 2 extracting the data to be compressed by means of ping pong operation, and alternately using a Hash table and a dictionary chain table for compressed encoding, step 3 splicing-processing non-fixed-length data after compressed encoding, and step 4 caching the compressed data and the spliced-processed data. According to the system and the method, Field Programmable Gata Array (FPGA) is adopted to realize the LZ77 compression function. By means of a data writing caching module and a data written-out caching module, the ping pong writing and ping pong reading function of data is realized. By means of a dictionary module, alternate update and use of the dictionary are realized so that an LZ77 compression algorithm module reaches the highest efficiency. Besides, by means of the parallel operation of the compression algorithm module and a non-fixed-length splicing-processing module, processing efficiency of the existing LZ77 compression algorithm is improved.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

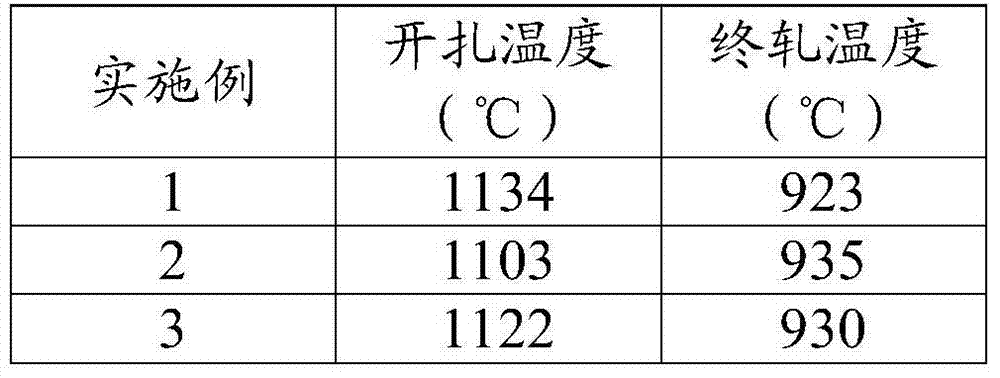

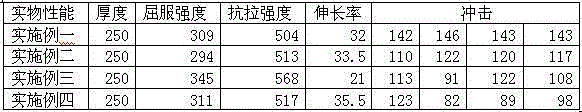

Extra thick quenched and tempered steel plate for ocean platform tooth bar and production method thereof

The invention which belongs to the technical field of steel concretely discloses an extra thick quenched and tempered steel plate for an ocean platform tooth bar and a production method thereof. The extra thick quenched and tempered steel plate for the ocean platform tooth bar comprises the following components, by weight, 0.14-0.18% of C, 0.15-0.35% of Si, 0.95-1.30% of Mn, equal to or less than0.015% of P, equal to or less than 0.005% of S, 2.35-2.55% of Ni, 0.35-0.55% of Cr, 0.40-0.60% of Mo, 0.020-0.050% of Nb, 0.010-0.030% of Ti, 0.020-0.045% of total Al, and the balance Fe and inevitable impurities, and the thickness of the steel plate reaches 177.8mm. The extra thick quenched and tempered steel plate for the ocean platform tooth bar, which is prepared through carrying out steps ofsmelting by an electric furnace, steel ingot casting by a die, TMCP rolling, fully enclosed quenching and tempering by a well type heating furnace, and the like, has the advantages of high yield strength, good elongation, excellent Z-directional performance, good low temperature impact toughness, good layered tearing resistance, and low production cost.

Owner:WUYANG IRON & STEEL +1

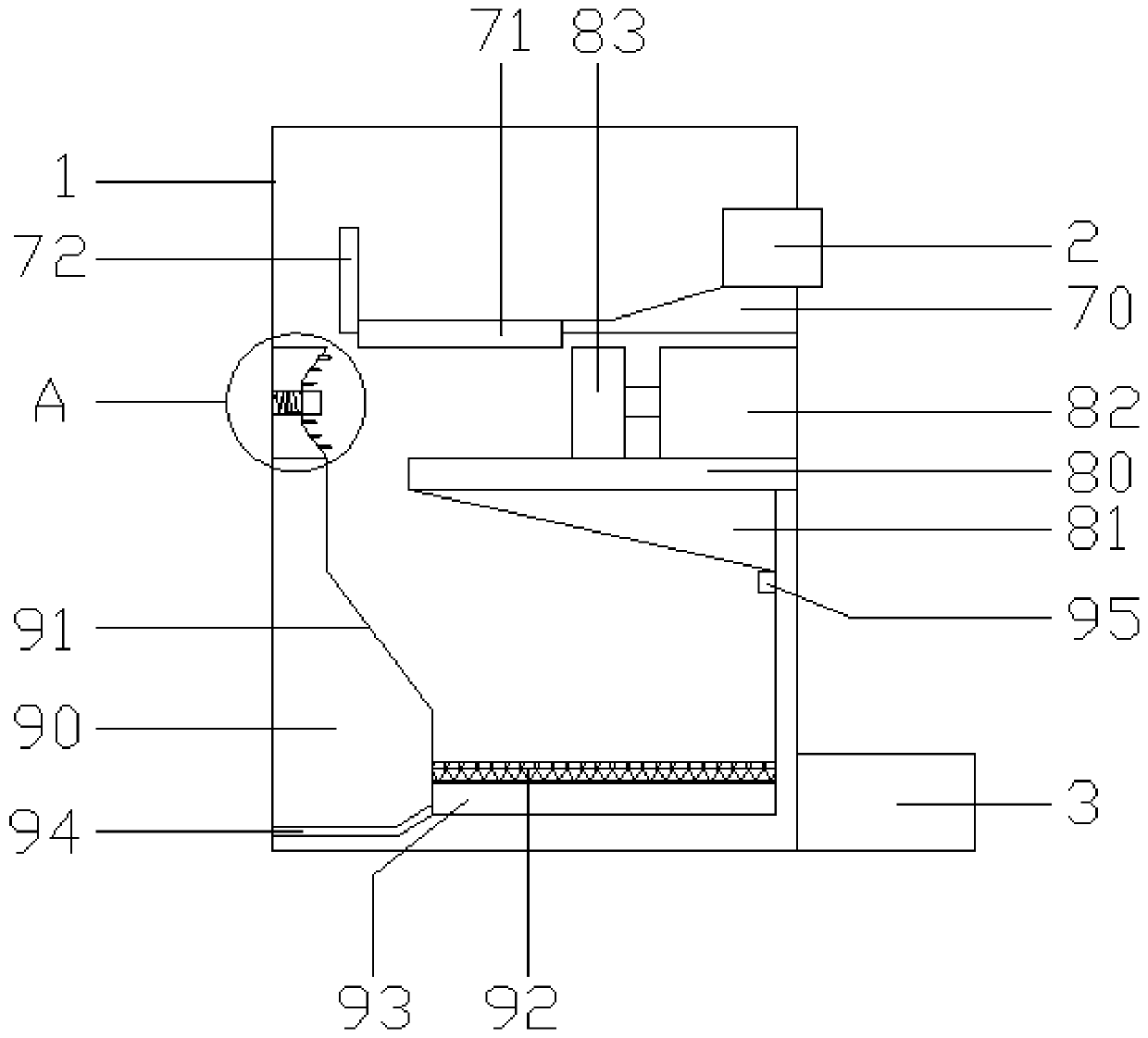

Beverage bottle recycling device

The invention discloses a beverage bottle recycling device. The beverage bottle recycling device comprises a device body, a bottle inlet, a gasket plate, a repairing door, a recycling bin door, locking heads, a material conveying mechanism, a compressing mechanism and a storing mechanism. The bottle inlet is formed in the right side of the device body, the gasket plate is arranged on the lower part of the bottle inlet, the repairing door is arranged on the outer side wall of the device body, the recycling bin door is arranged on the lower part of the repairing door, the locking heads are arranged on the repairing door and the recycling bin door, and the device body is internally and successively provided with the material conveying mechanism, the compressing mechanism and the storing mechanism from top to bottom. Compared with the prior art, the beverage bottle recycling device has the advantages that the structure is simple, design is reasonable, fast recycling, compressing and storing of plastic beverage bottles can be realized, the collecting efficiency is improved, and the collecting cost is reduced.

Owner:海盐明盛塑业有限公司

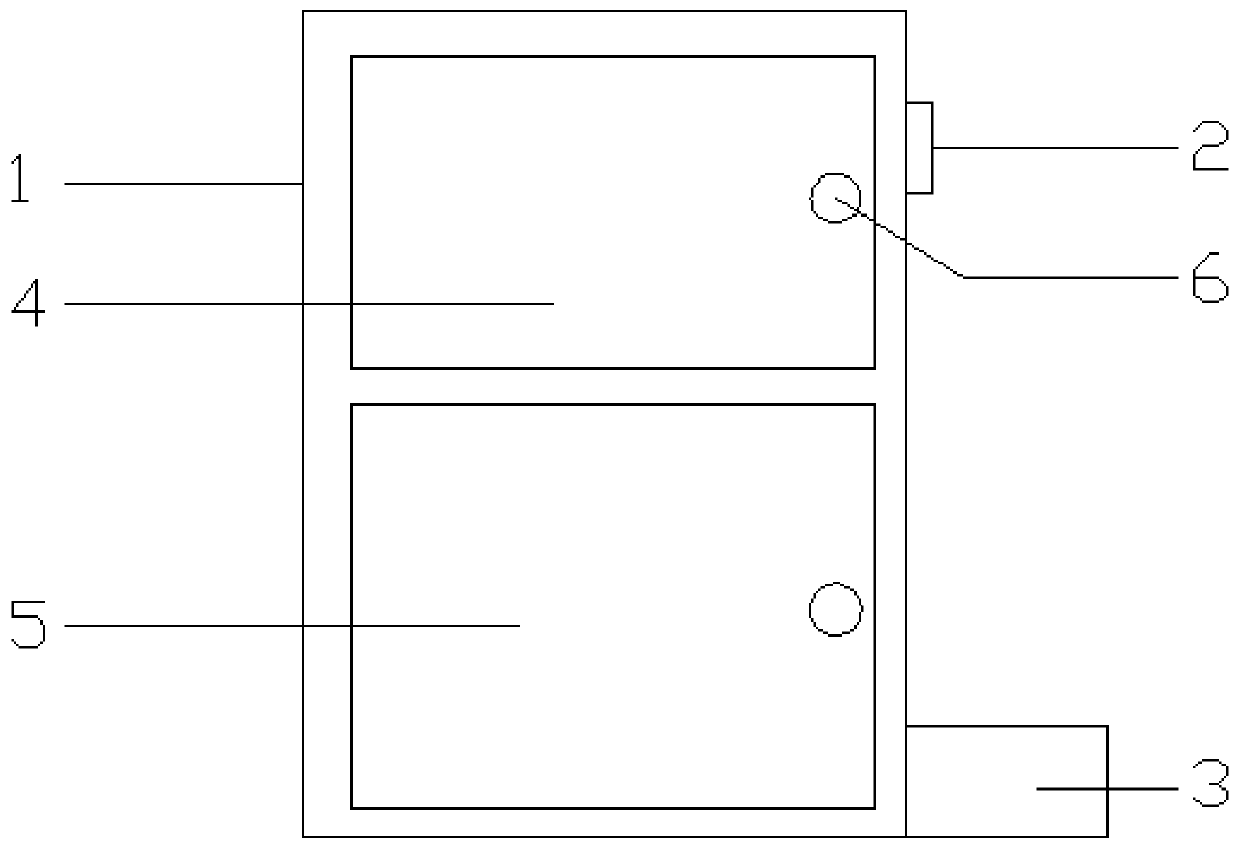

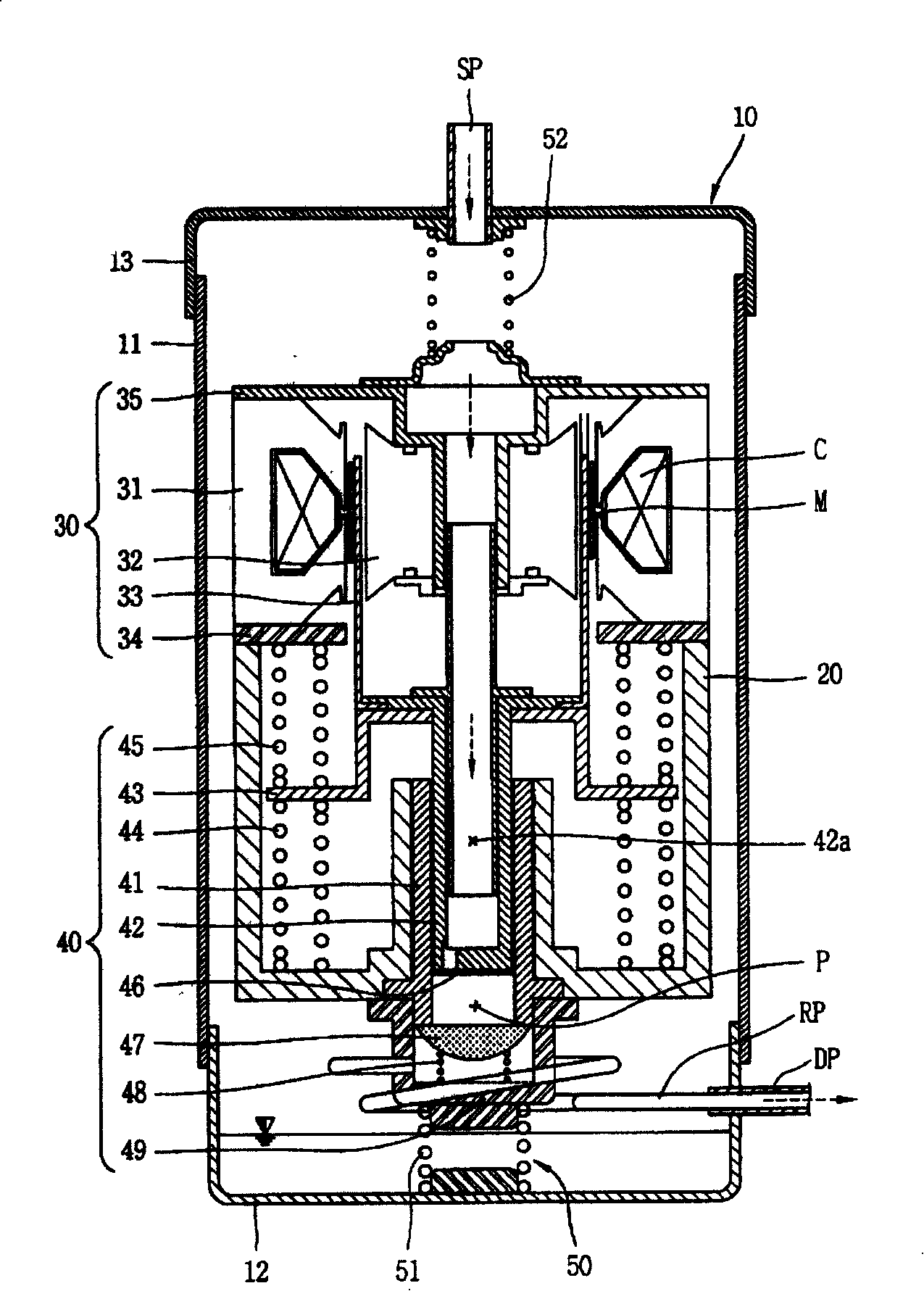

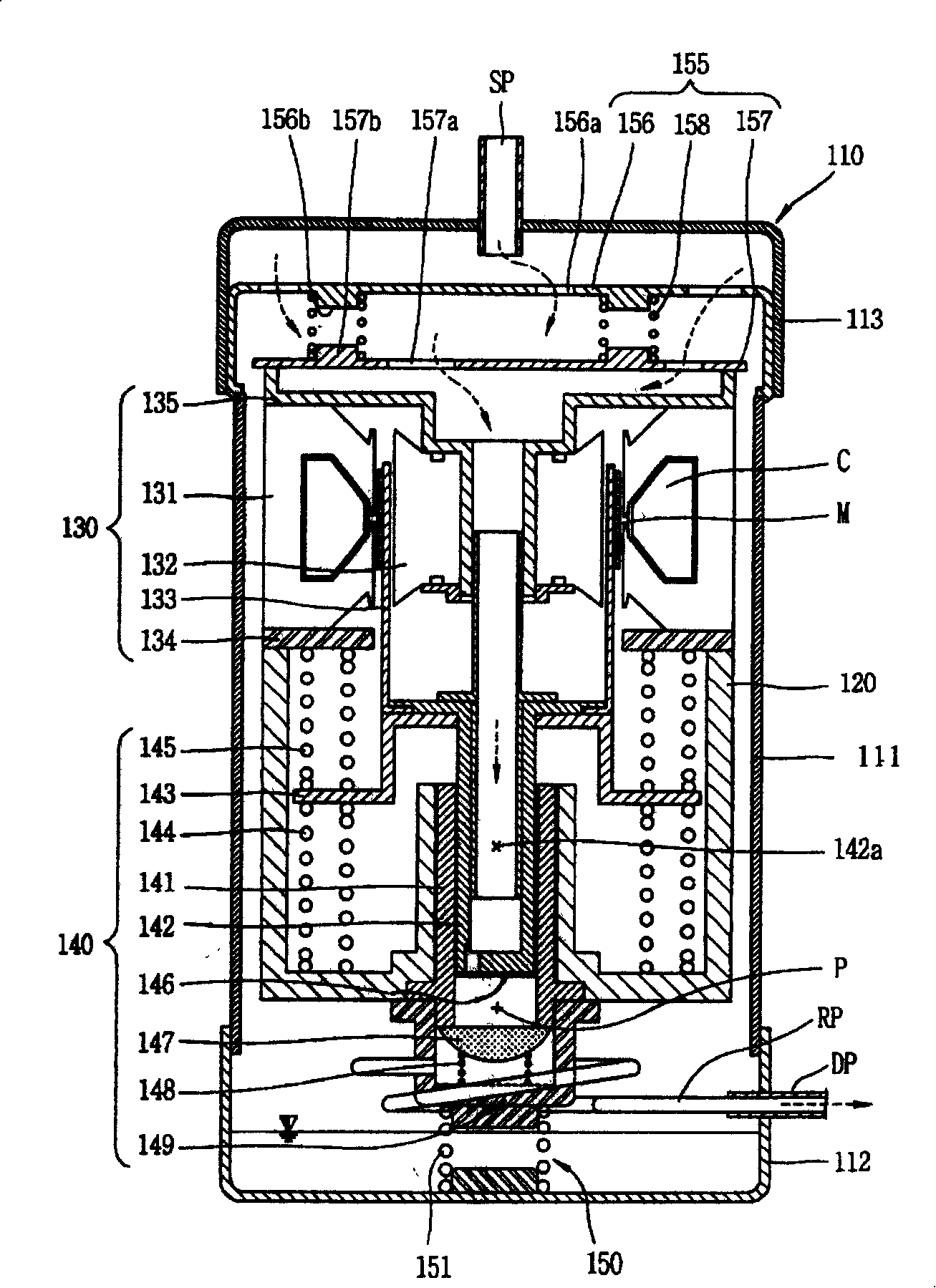

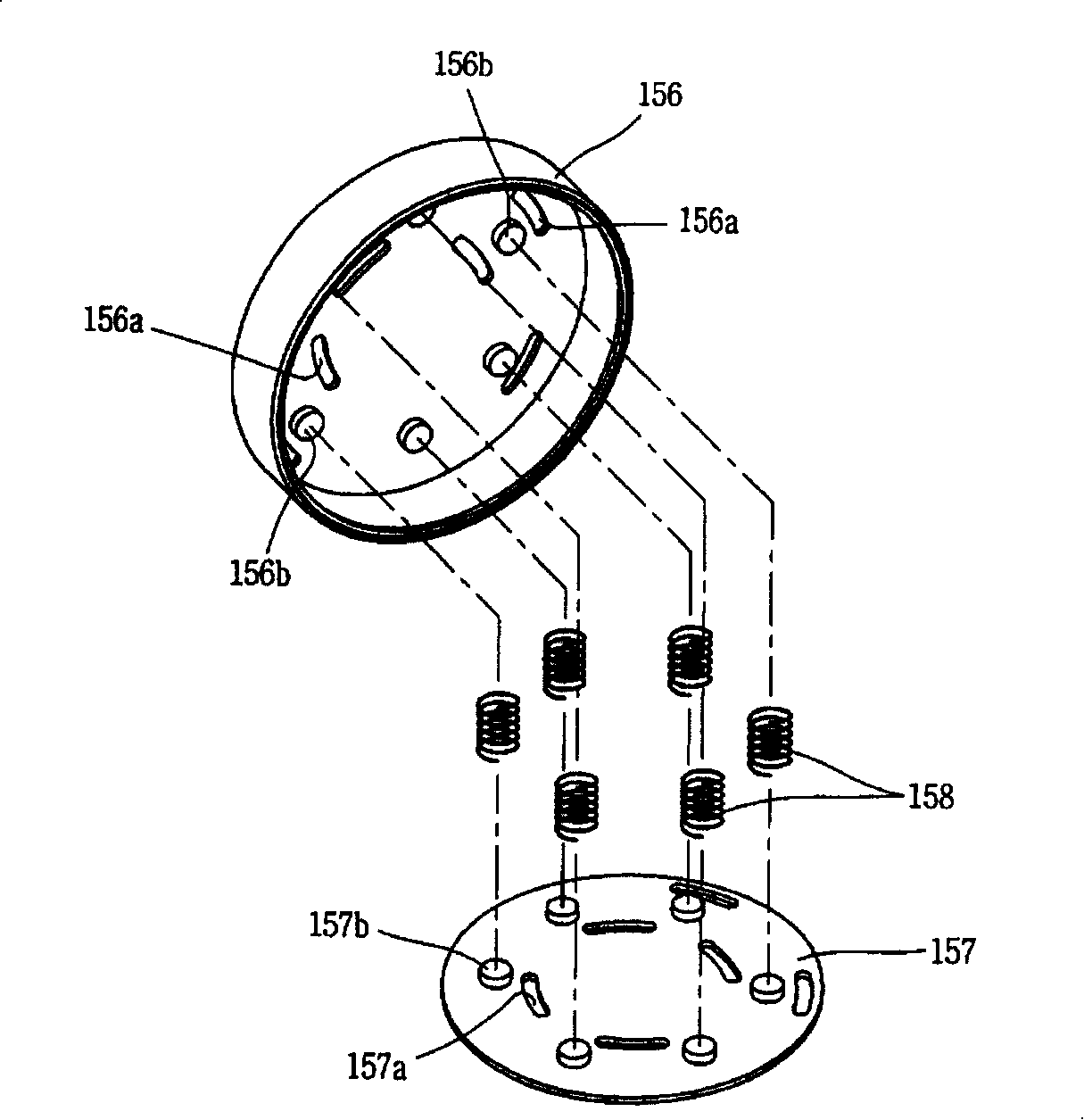

Supporting apparatus for reciprocating compressor

InactiveCN101205888AStable supportImprove reliabilityPositive displacement pump componentsPiston pumpsReciprocating motionEngineering

The invention provides a support device for a reciprocating compressor, comprising an outer shell, a compressor body, a fixed side support plate which is fixed on and combined with the outer shell, a movable side support plate which corresponds to the fixed side support plate, is combined with the compressor body and vibrates together with the compressor body, and an elastic member which is arranged between the fixed side support plate and the movable side support plate and can absorb the vibration of the compressor body, wherein, the compressor body comprises a reciprocating movement motor which is arranged inside the outer shell and of which a rotor can make the straight line reciprocating movement, and a piston which is combined with the reciprocating movement motor and can make the straight line reciprocating movement in a cylinder and simultaneously compress refrigerants. The support device of the invention can stably support the compressor body and prevent the bumping between the compressor body and the outer shell, thereby improving the reliability of the compressor; moreover, refrigerant through holes arranged on the support plates are distributed in different lines, thereby increasing the intake of the refrigerants, keeping a certain compression ratio and enhancing the performance of the compressor.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

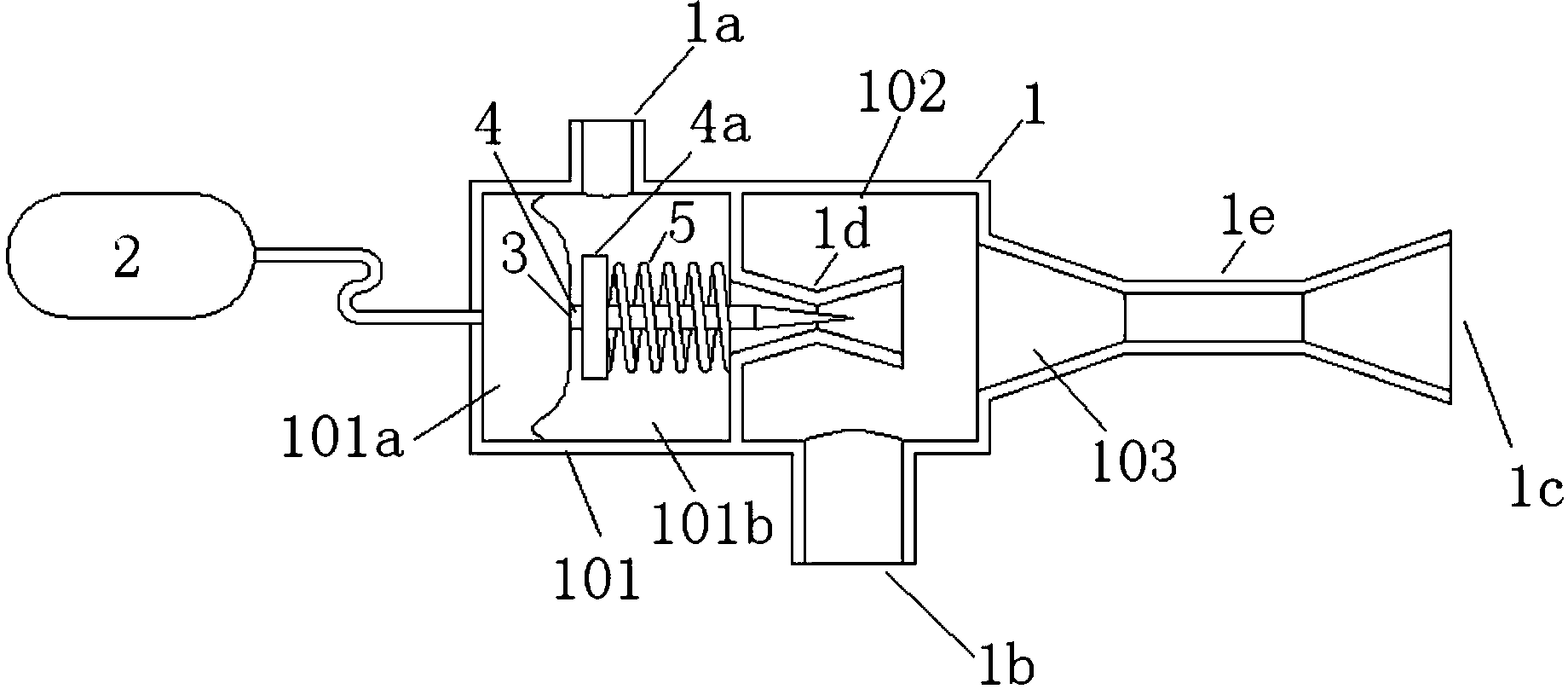

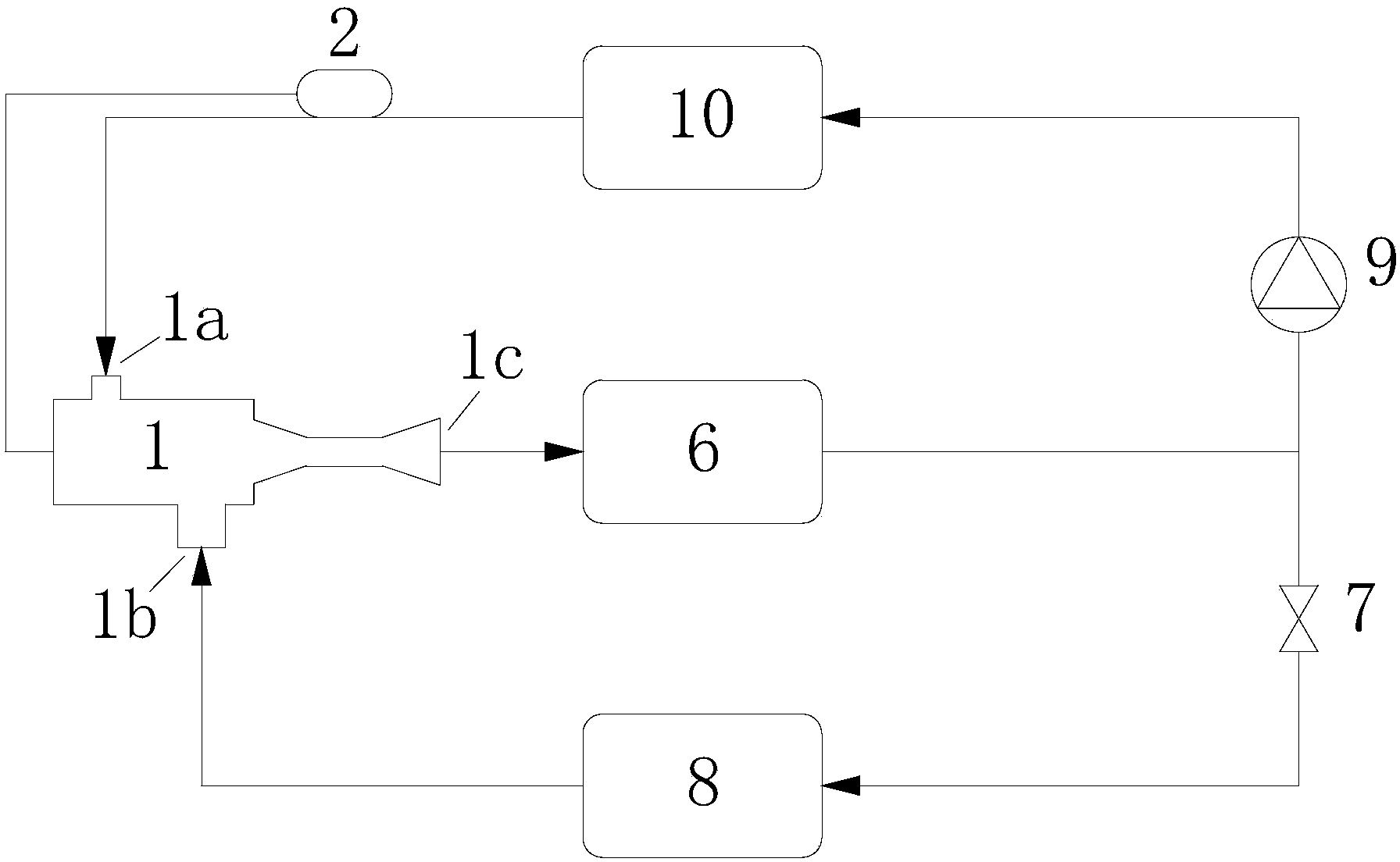

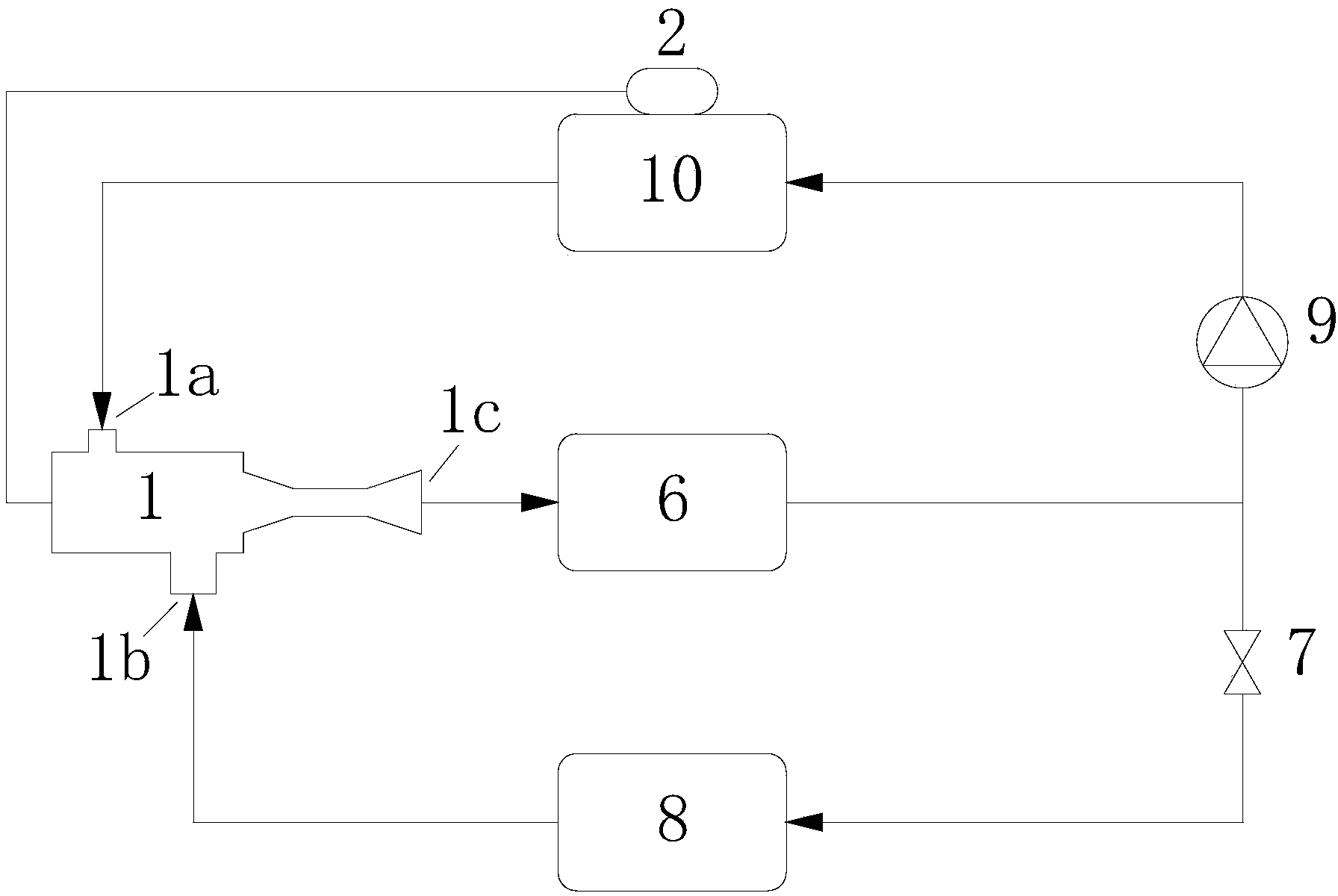

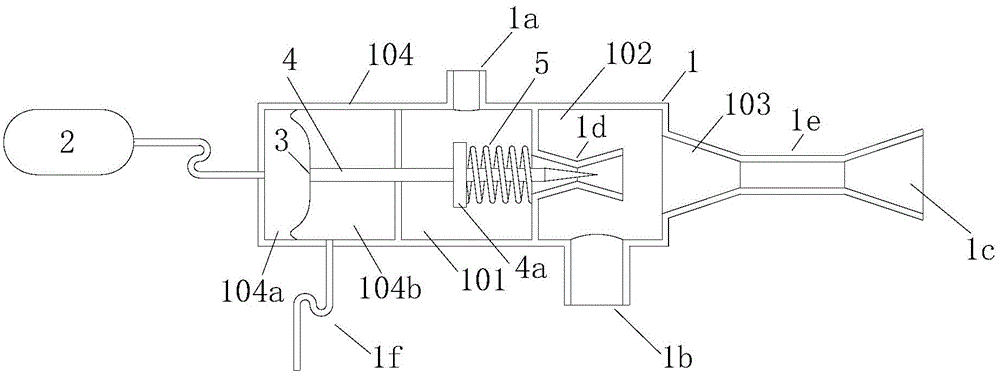

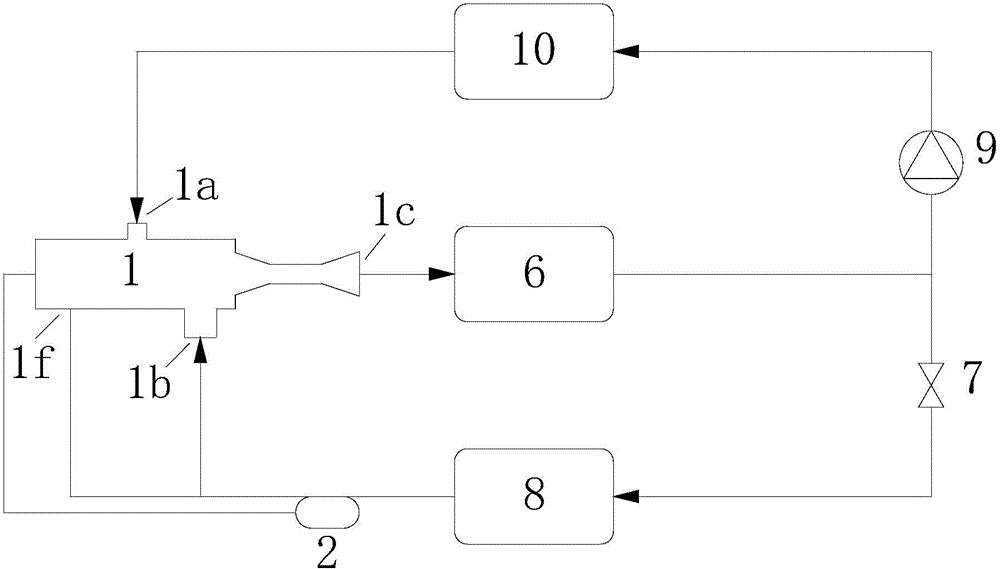

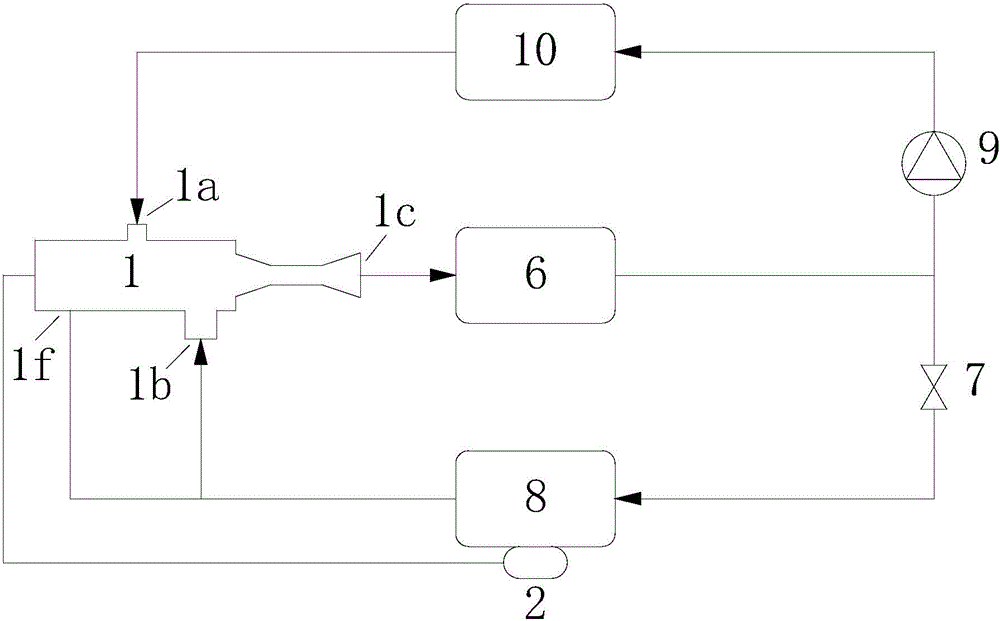

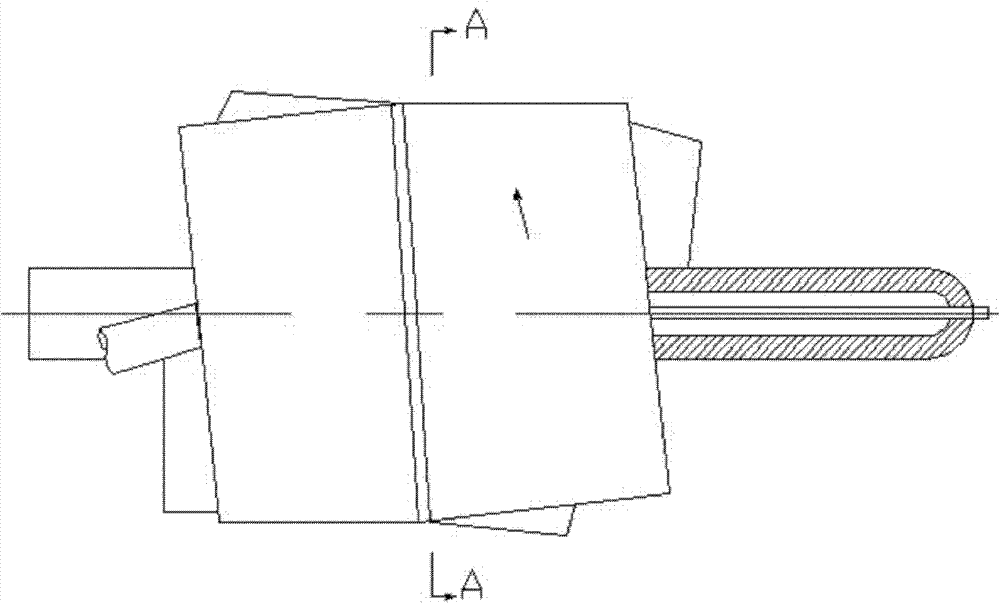

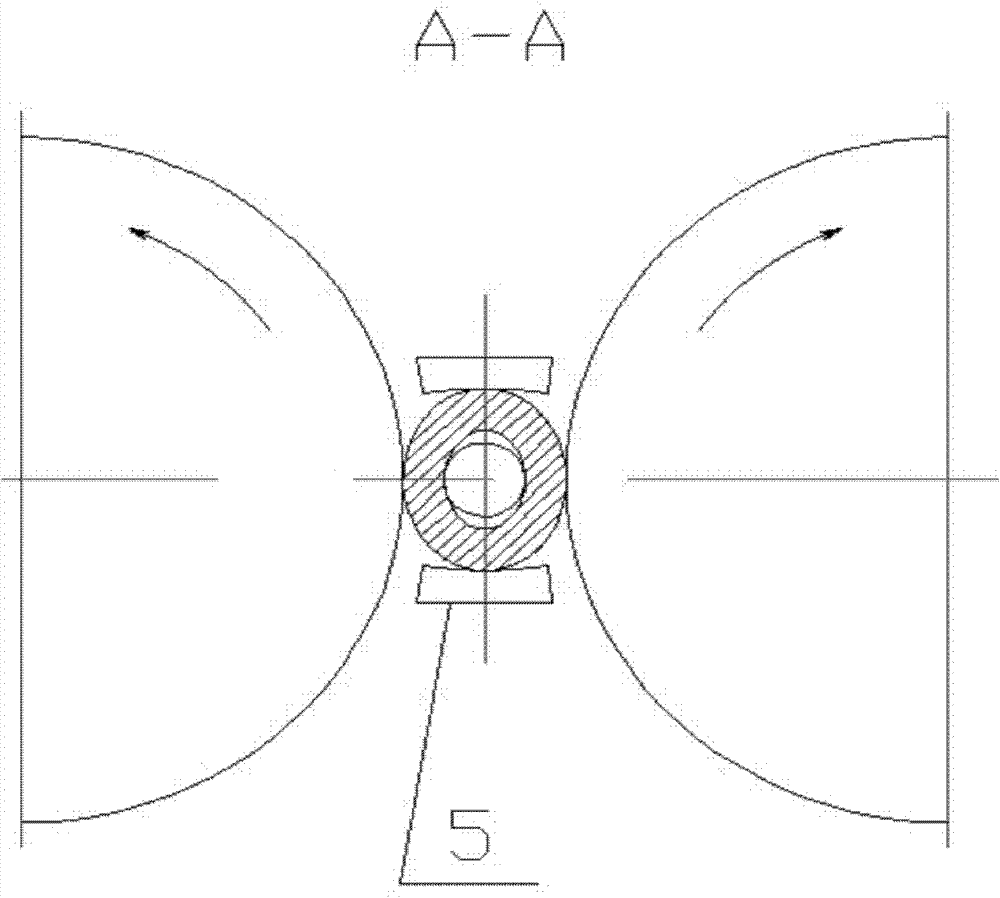

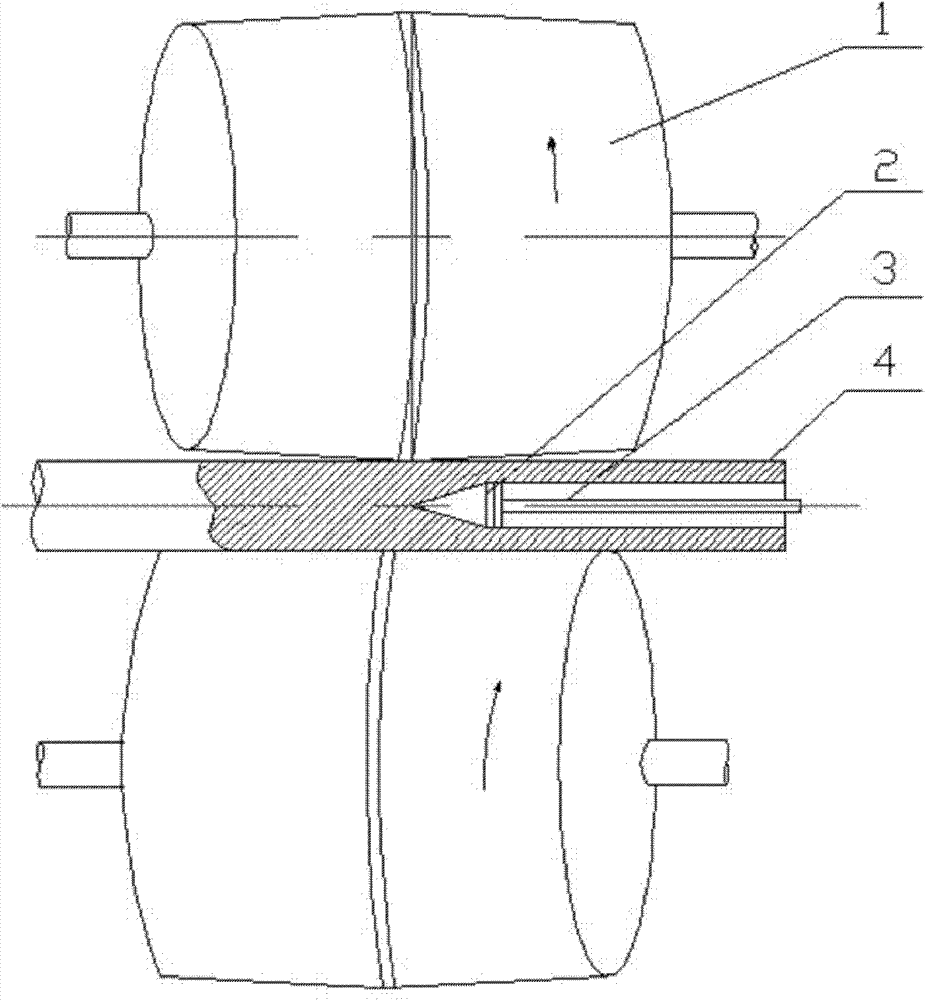

Ejector capable of automatically regulating area ratio along with generating temperature and jet type refrigerating machine

InactiveCN104075509AChange the area ratioGuaranteed compression ratioMechanical apparatusFluid circulation arrangementAuto regulationWorking fluid

The invention discloses an ejector capable of automatically regulating an area ratio along with generating temperature and a jet type refrigerating machine with the same. The ejector capable of automatically regulating the area ratio along with the generating temperature comprises an ejector cavity and a thermometer bulb communicated with a drive chamber, wherein the ejector cavity comprises a steam chamber with a working fluid nozzle, and a regulating cone coaxial with the working fluid nozzle is arranged therein; a regulating piece for dividing the steam chamber into the drive chamber and a driven chamber independent from each other is arranged therein; the regulating piece regulates the axial movement of the regulating cone in real time according to pressure signals of the thermometer bulb so as to regulate the fluid nozzle flow area. The ejector capable of automatically regulating the area ratio along with the generating temperature breaks through the restraints of traditional ideas, the working fluid nozzle flow area is changed through the position change of the regulating cone in the axial direction of the working fluid nozzle due to the deformation or move caused by the regulating piece change along the generating temperature, the pressure at a working fluid inlet, the pressure of the thermometer bulb and a spring, and then the ejector area ratio is changed, and the ejector can work under the best size.

Owner:ZHEJIANG UNIV

Ejector with area ratio automatically adjusted along with evaporation temperature and ejection type refrigerating machine

InactiveCN104089439AArea ratio changeGuaranteed compression ratioMechanical apparatusCompression machinesWorking fluidEngineering

The invention discloses an ejector with the area ratio automatically adjusted along with evaporation temperature. The ejector comprises a vapor chamber, an adjustment chamber and a thermal bulb, wherein a working fluid nozzle is arranged on a gas outlet of the vapor chamber, and a coaxially arranged adjusting cone is arranged in the working fluid nozzle; an adjusting piece is arranged in the adjustment chamber; an inner cavity of the thermal bulb is communicated with a driving chamber, and the thermal bulb is used for sensing the temperature of ejected fluid, converting the temperature into a pressure signal and outputting the pressure signal; according to the pressure signal of the thermal bulb, the adjusting cone is adjusted by the adjusting piece in real time to axially move, and thus the flow area of the working fluid nozzle can be adjusted. The invention further discloses a refrigerating machine with the ejector. The ejector breaks through constraints of a traditional thought, through changes of the position of the adjusting cone in the axial direction of the working fluid nozzle caused by deformation of a membrane along the evaporation temperature under the combined action of the pressure of an outlet of an evaporator, the pressure of the thermal bulb and a spring, the flow area of the working fluid nozzle is changed, the area ratio of the ejector is changed, and thus the ejector can work with the optimum size.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

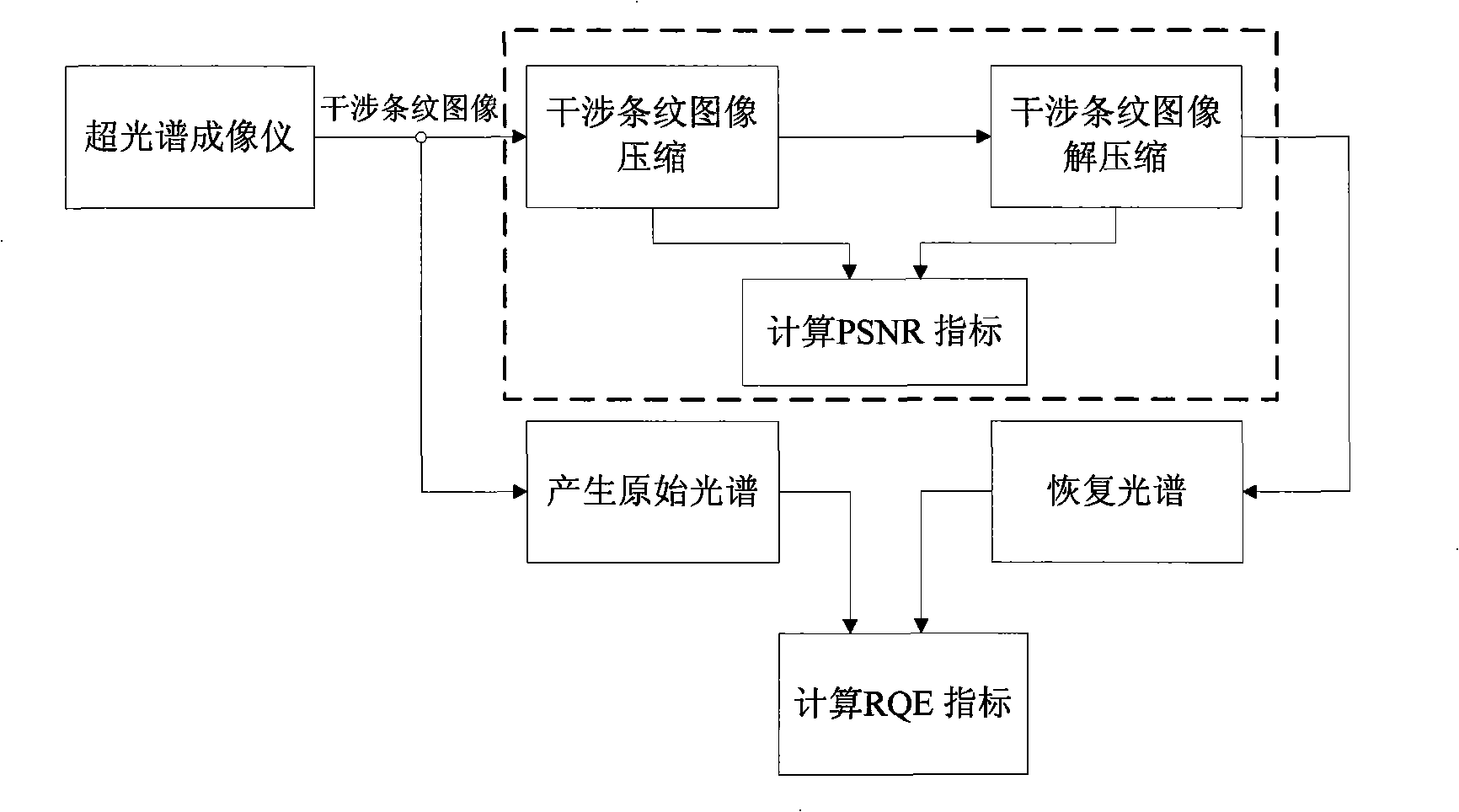

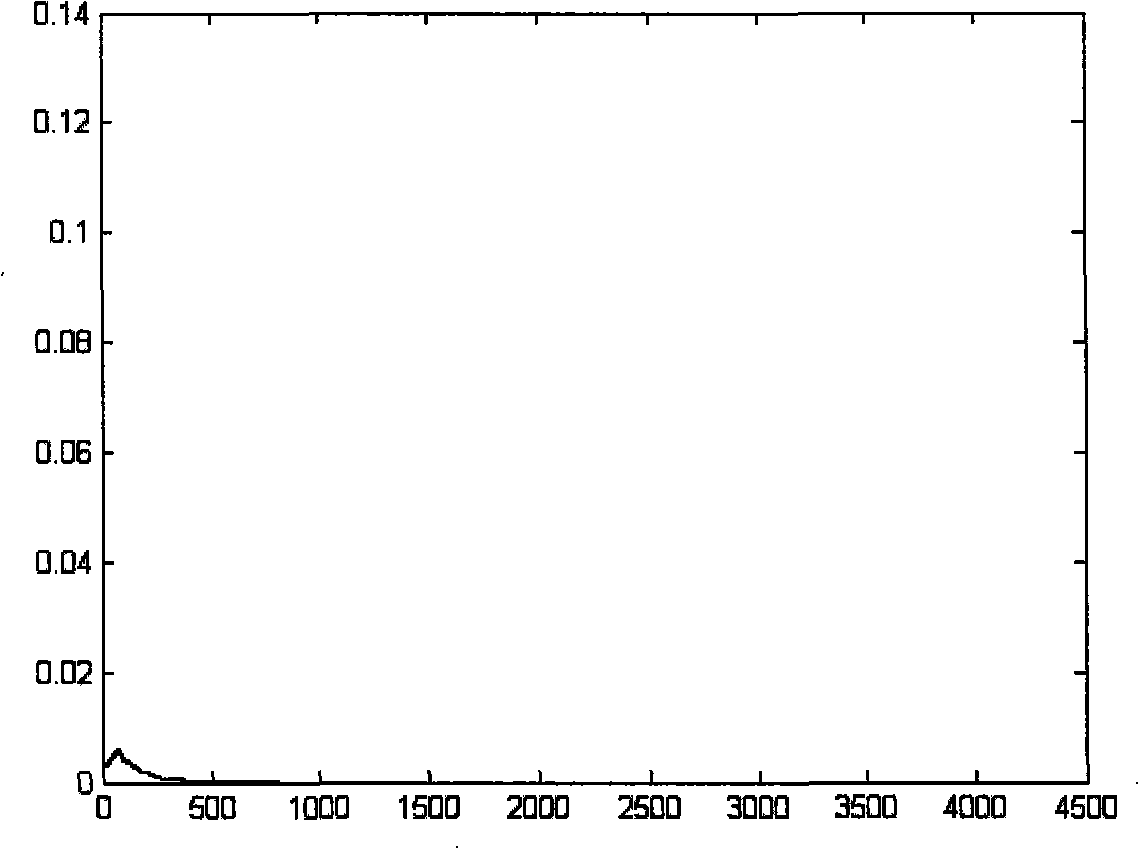

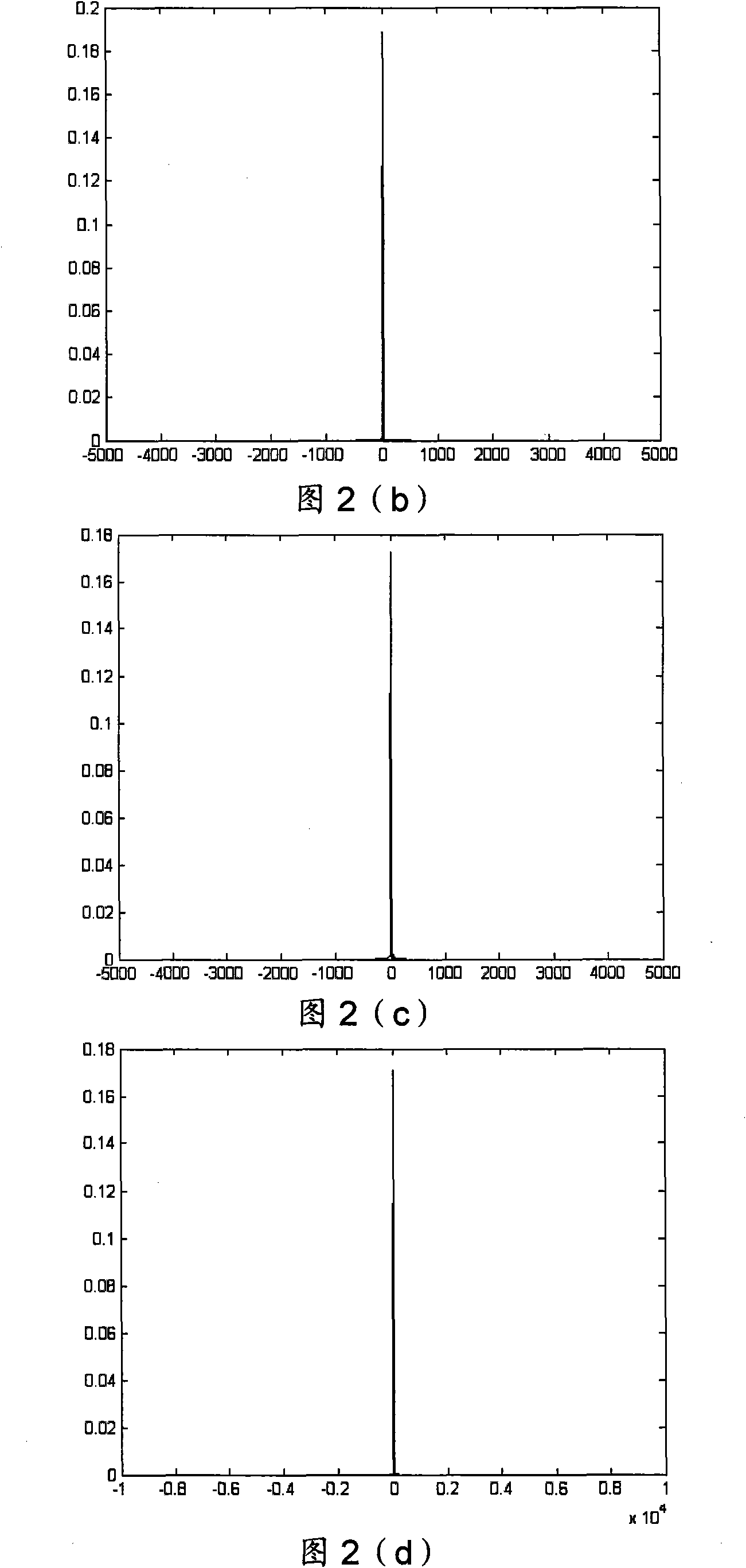

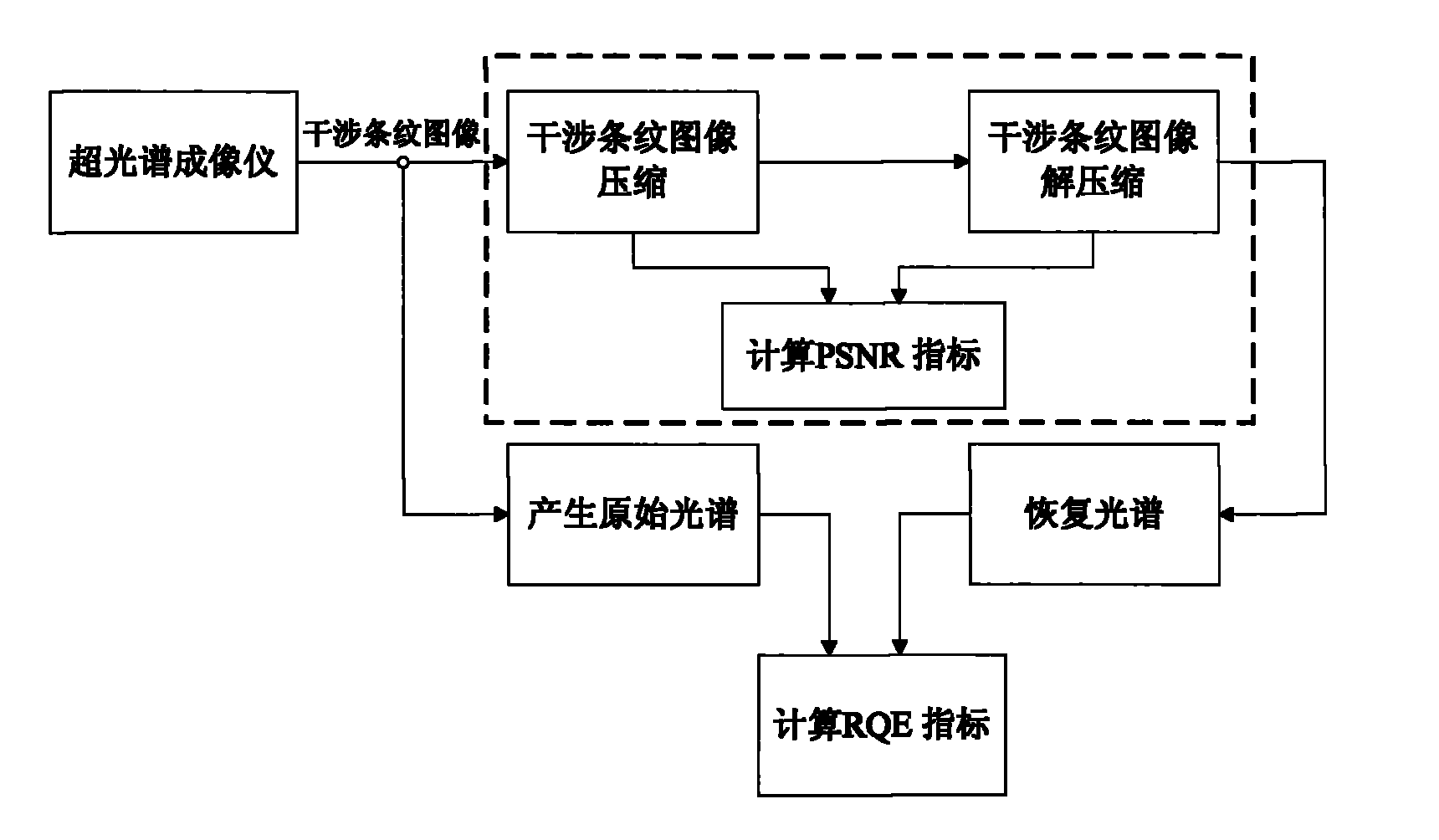

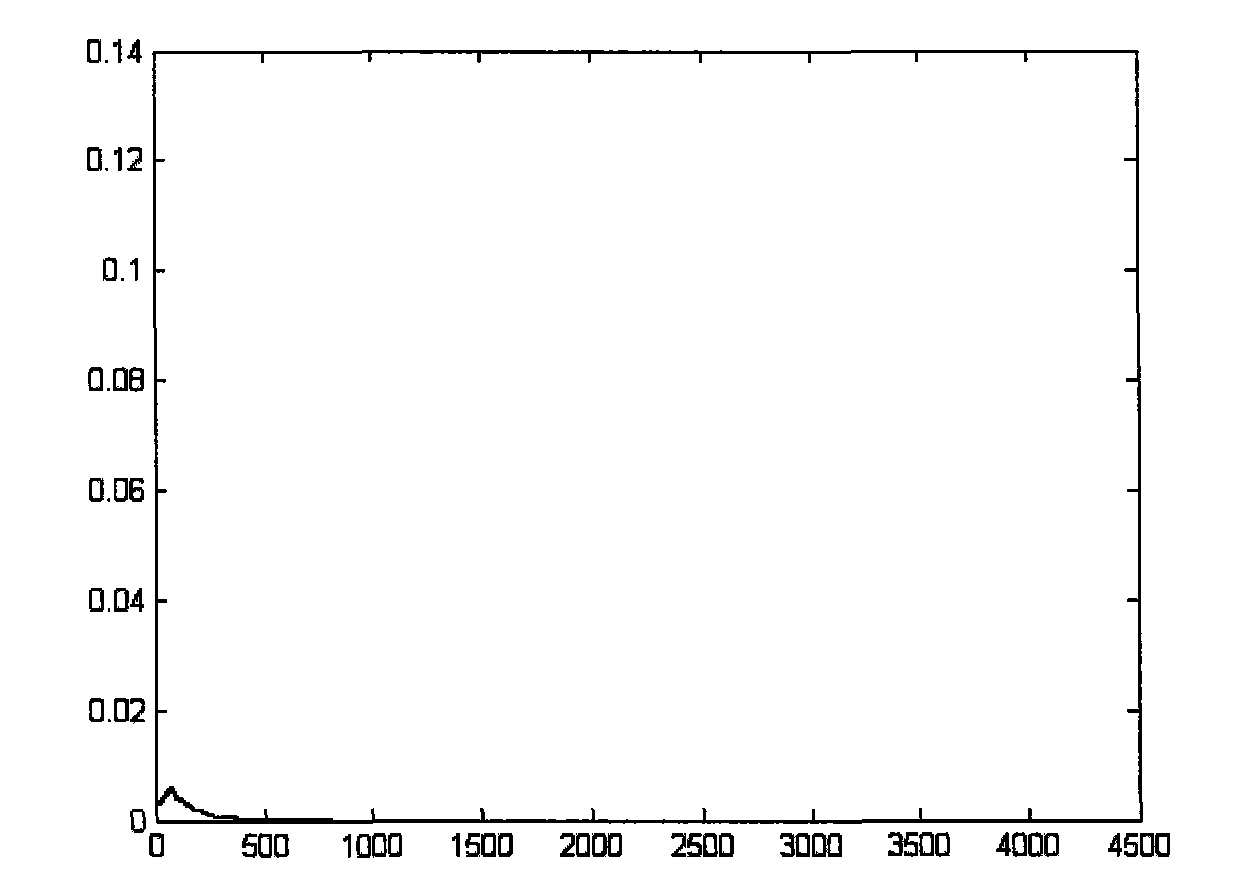

Near-lossless real-time compression method for satellite-borne hyper-spectral interference fringe image

ActiveCN101576412AHigh speedLarge distortion rateInterferometric spectrometryImage codingTreatment differenceTime compression

The invention provides a near-lossless real-time compression method for a satellite-borne hyper-spectral interference fringe image. The method obtains the correlative characteristic of the interference fringe image by a spectral decorrelation and entropy coding method; according to the correlative characteristic of the image, the spectral decorrelation treatment is carried out on the interference fringe with a large optical path difference so as to obtain the spectral decorrelation treatment difference image; subsequently, according to the data distribution probability of the difference image, a quantization coding list suitable for the image is designed so as to carry out the lossless quantization on the value with the appearance probability more than or equal to 60% and carry out loss non-uniform quantization on the value with the appearance probability less than 60%; and finally a DPCM compression with a low compression ratio is adopted. The method has the advantages that the compressed and decompressed interference fringe image has small distortion, the compression and decompression treatment speed is quick and the real-time performance is good.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

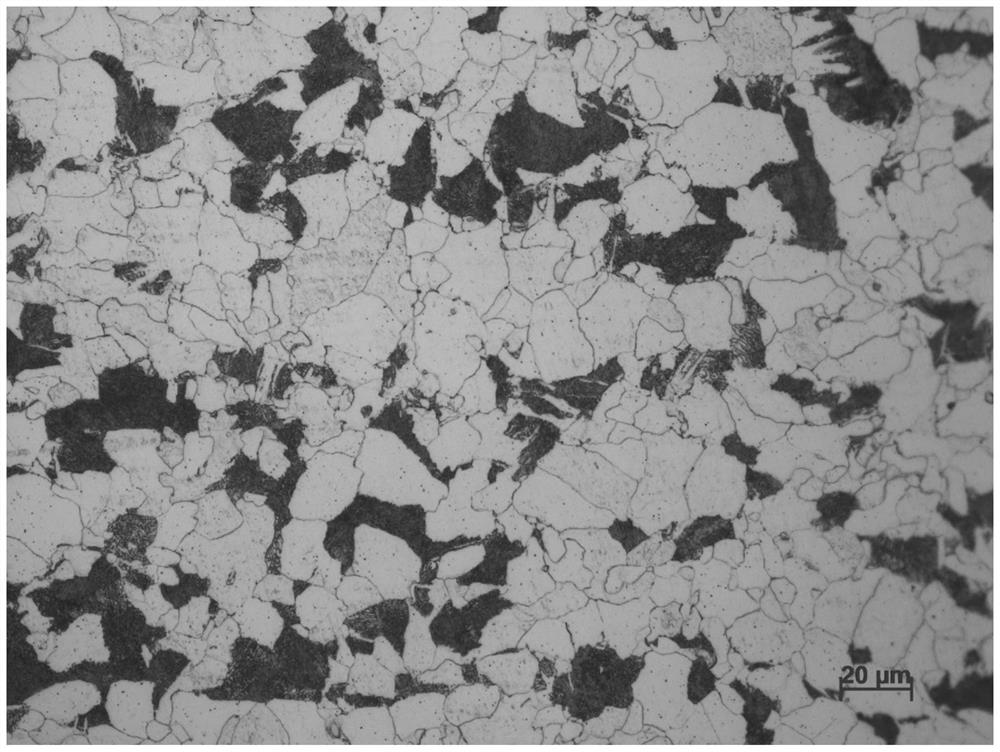

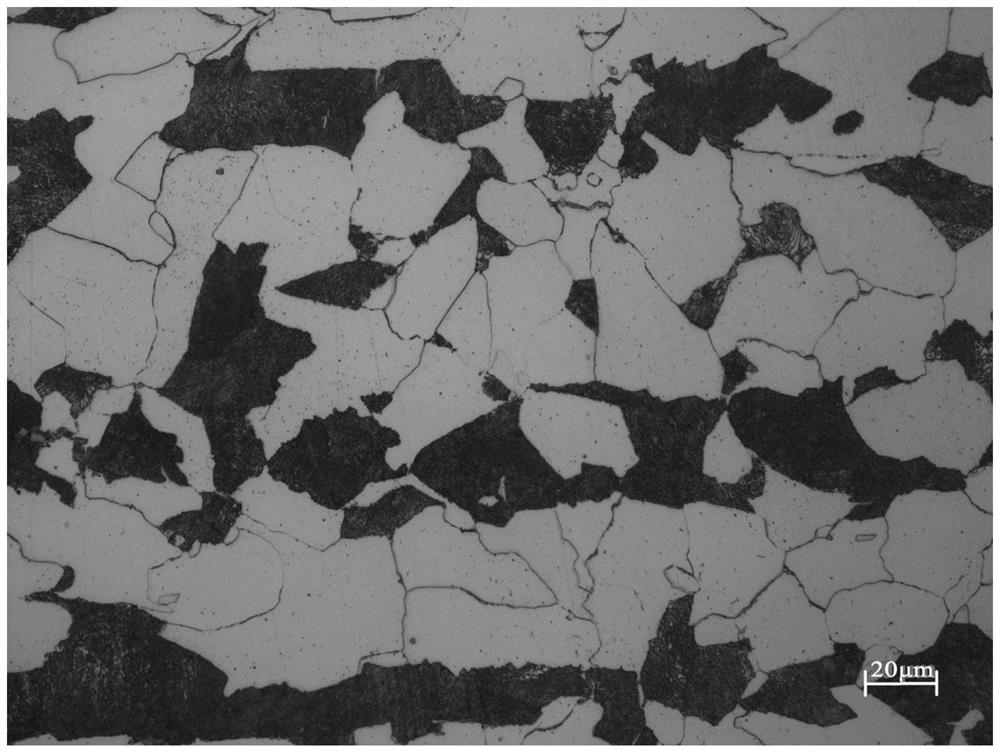

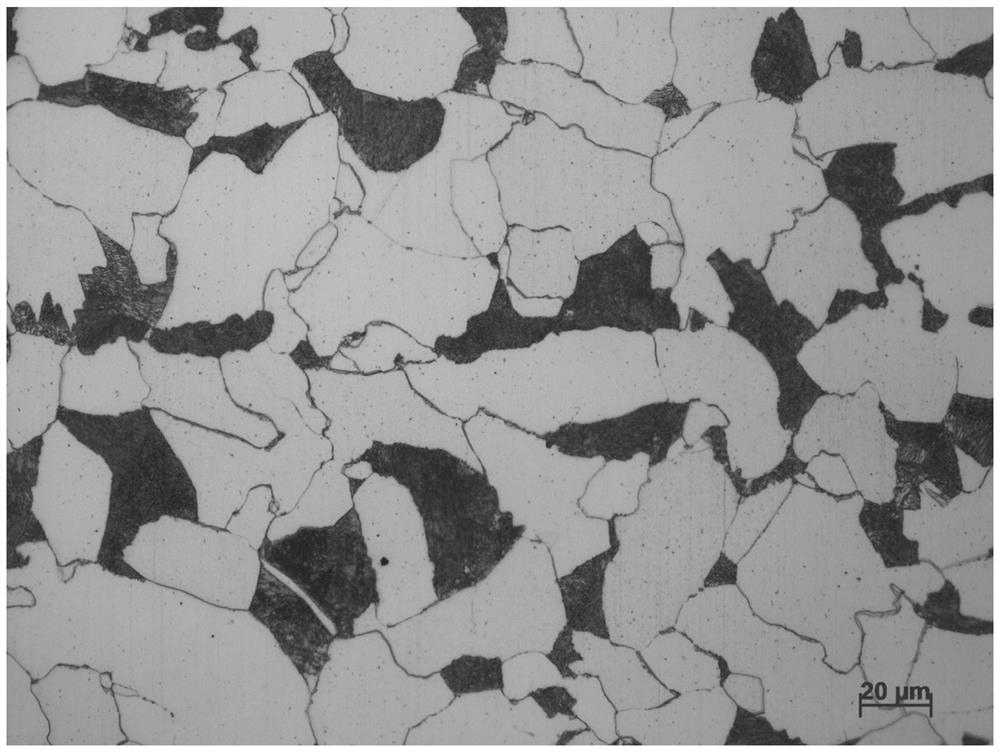

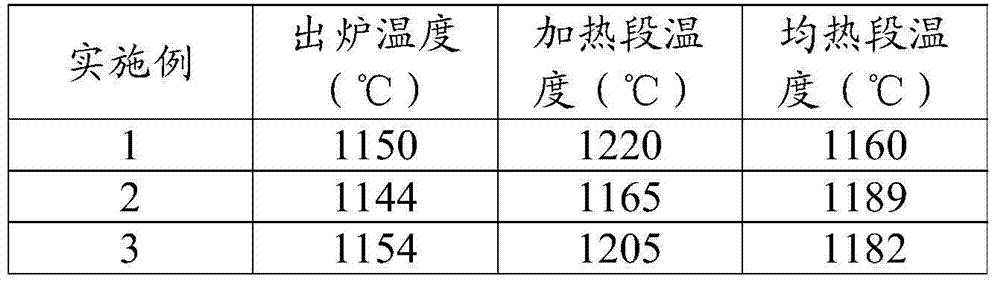

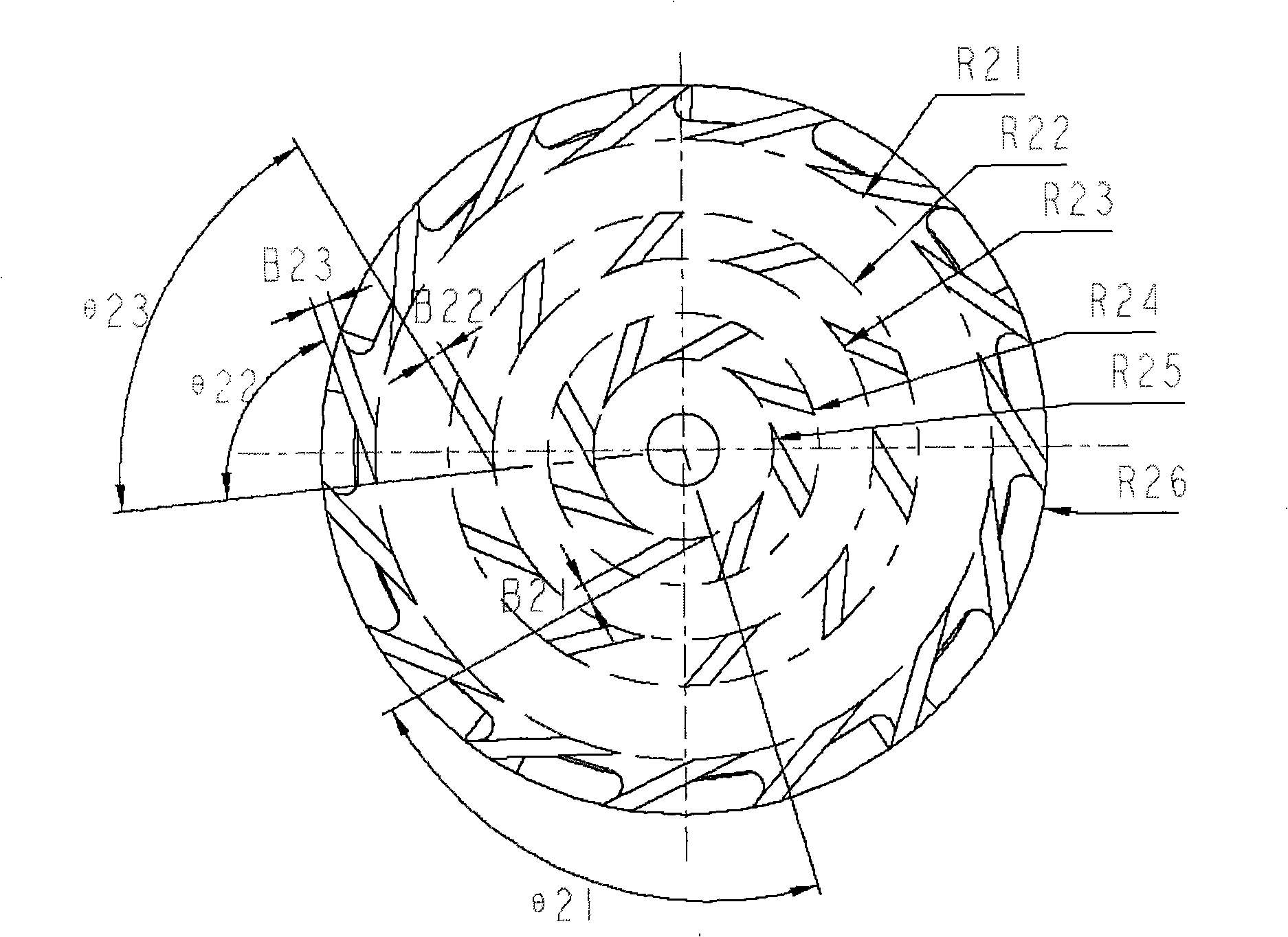

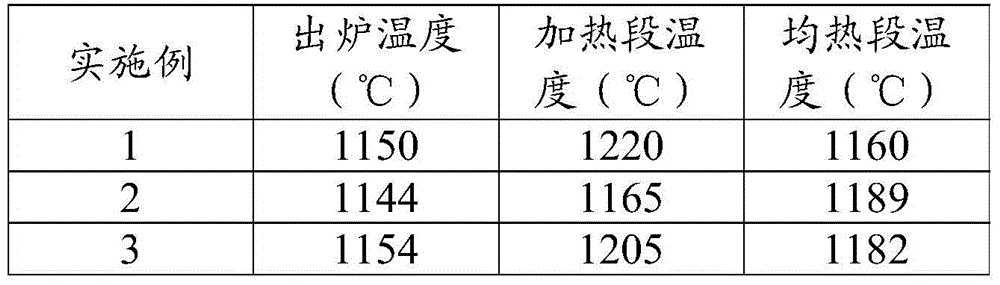

Micro-titanium alloying Q355B medium-thickness steel plate and low-cost production method therefor

ActiveCN112322982AImprove rolling efficiency and control performance uniformityRefined organizationProcess efficiency improvementSteel platesFerrous metallurgy

The invention discloses a micro-titanium alloying Q355B medium-thickness steel plate and a low-cost production method therefor, and belongs to the technical field of ferrous metallurgy. The steel plate comprises the following chemical components in percentage by mass: 0.15-0.18% of C, less than or equal to 0.24% of Si, less than or equal to 1.60% of Mn, 0.020-0.045% of Al, 0.020-0.040% of Ti, lessthan or equal to 0.10% of Cr, less than or equal to 0.025% of P, less than or equal to 0.008% of S, less than or equal to 0.080% of N, and the balance of iron and inevitable impurity elements. In order to solve the technical problem that in the prior art, the continuous production rhythm can be affected due to the fact that a blank needs to be kept warm in the rolling process of a 30-40 mm medium-thickness Q355B steel plate, the micro-titanium alloying Q355B medium-thickness steel plate has the advantages that precious elements such as V, Nb and Cu are not added, controlled rolling is not needed, and the production rhythm can be greatly improved.

Owner:SHAGANG GROUP +1

Steel for saw blades and production method of steel

ActiveCN104498840AReasonable ingredient controlImprove performanceChemical compositionSmelting process

The invention discloses steel for saw blades. The steel comprises the following chemical components in percentage by mass: 0.69-0.75% of C, 0.30-0.60% of Si, 1.10-1.40% of Mn, less than or equal to 0.15% of Cr, less than or equal to 0.10% of Ni, less than or equal to 0.15% of Cu, less than or equal to 0.08% of Mo, less than or equal to 0.04% of Sn, less than or equal to 0.02% of Sb, less than or equal to 0.025% of Ti, less than or equal to 0.040% of P, less than or equal to 0.040% of S, and the balance of Fe. The invention also discloses a production method of the steel for the saw blades. The steel for saw blades is reasonable in composition control to ensure the compression ratio of steel products, is good in performance, and does not have crackles on the surface. The production method of the steel for saw blades is simple, and a specific smelting process and narrow composition control of carbon are adopted to produce the steel for saw blades, which meets a requirement on narrow composition control during subsequent steel rolling heat treatment.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Extra thick quenched and tempered steel plate for ocean platform tooth bar and production method thereof

Owner:WUYANG IRON & STEEL +1

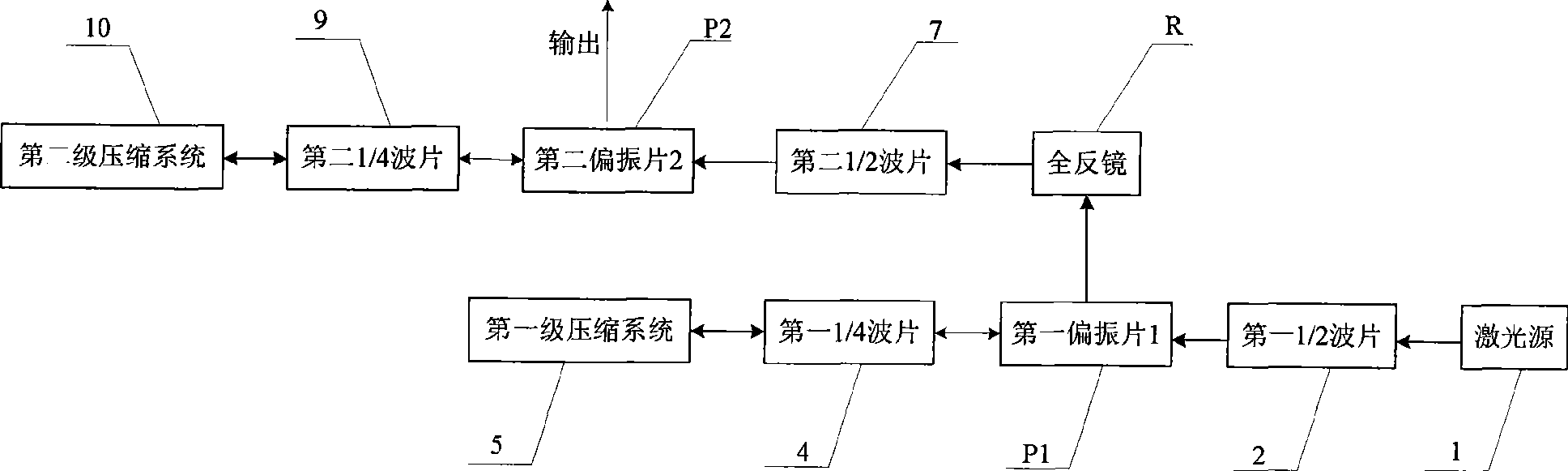

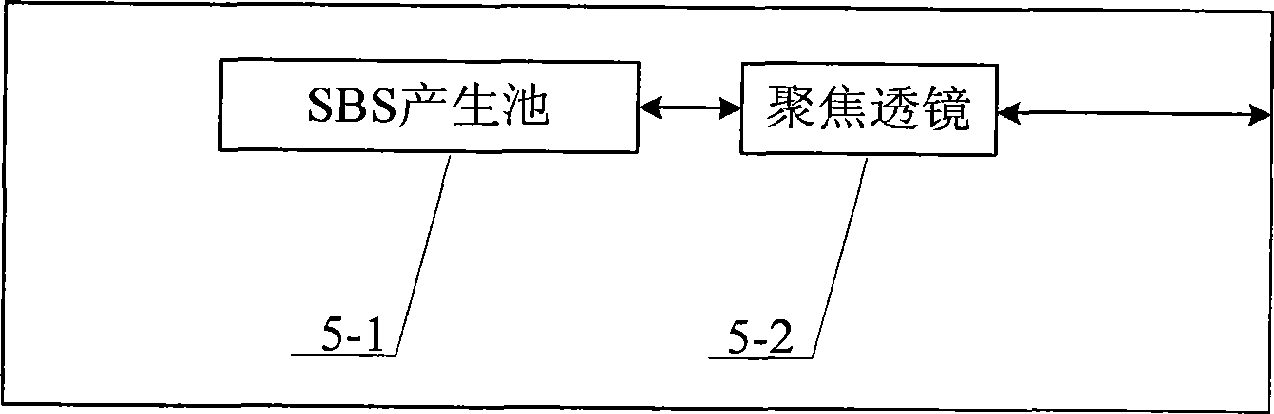

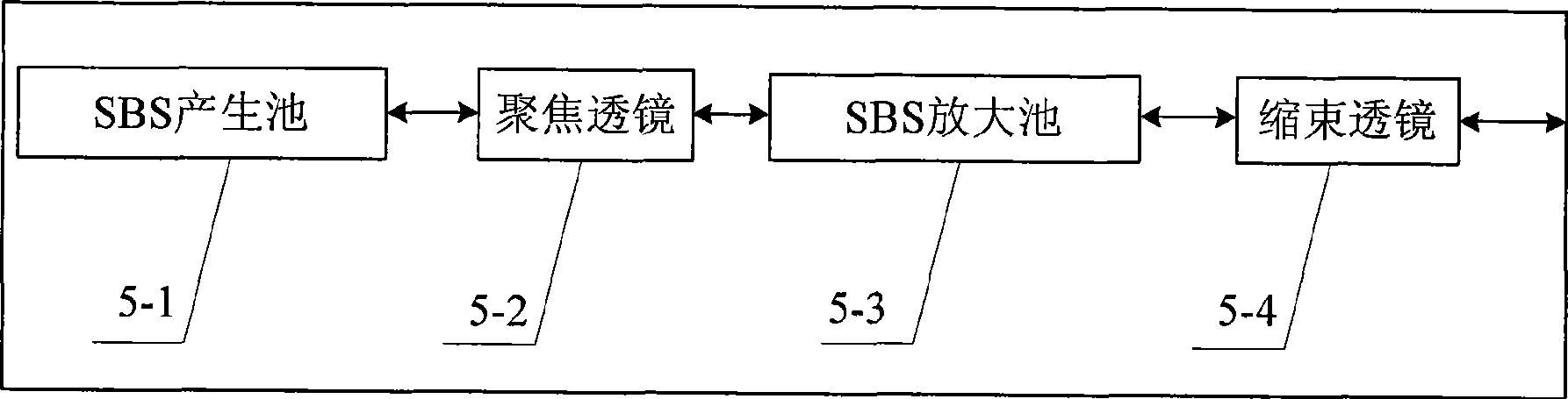

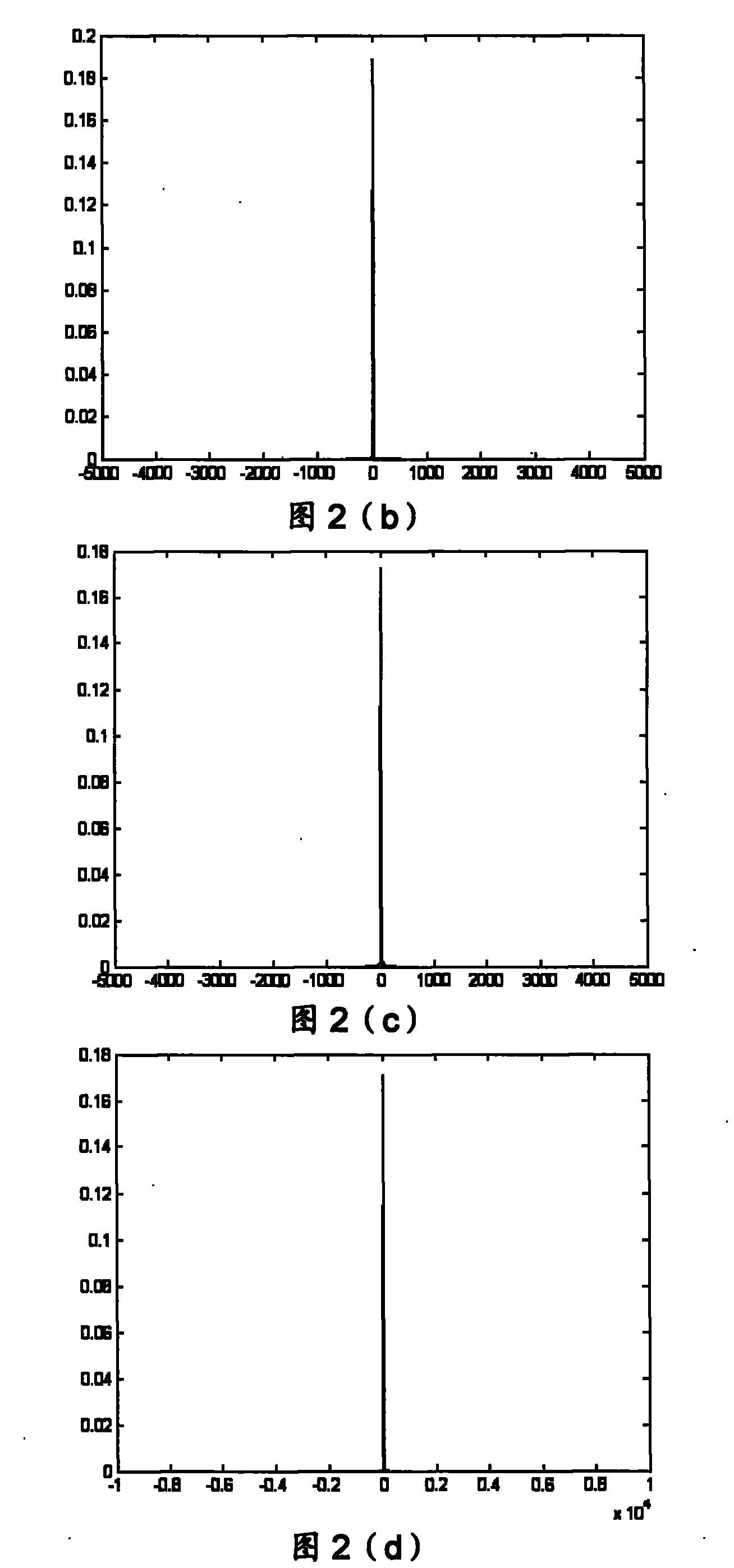

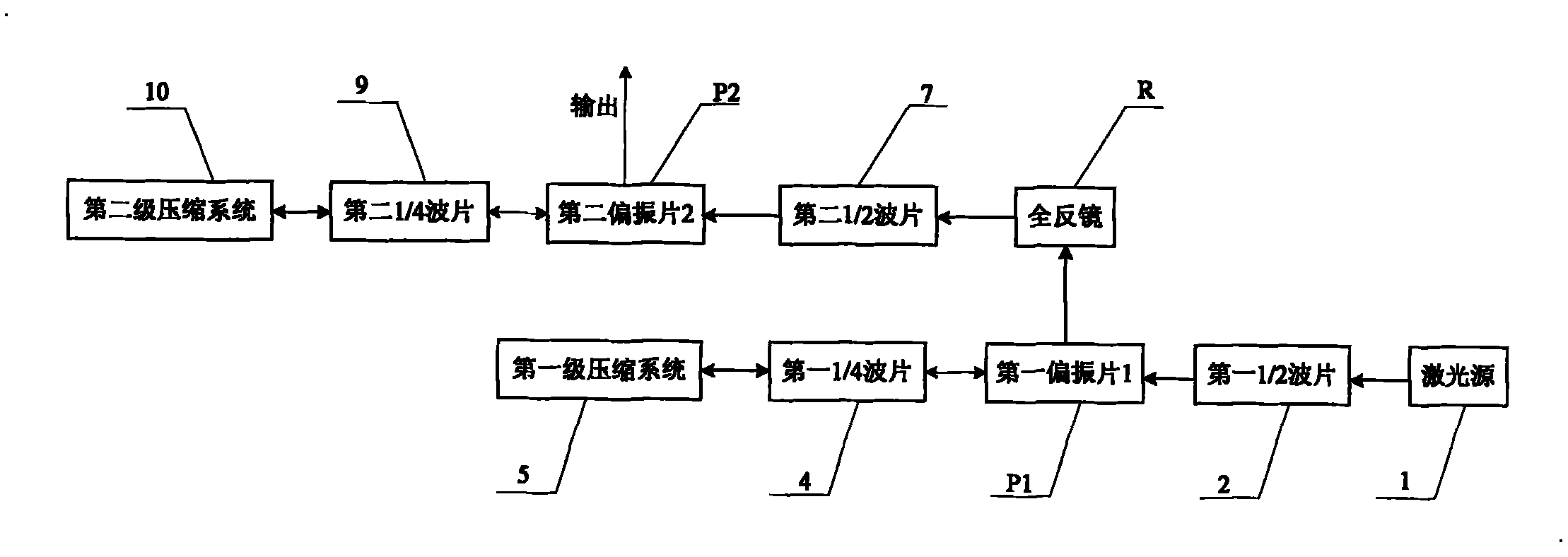

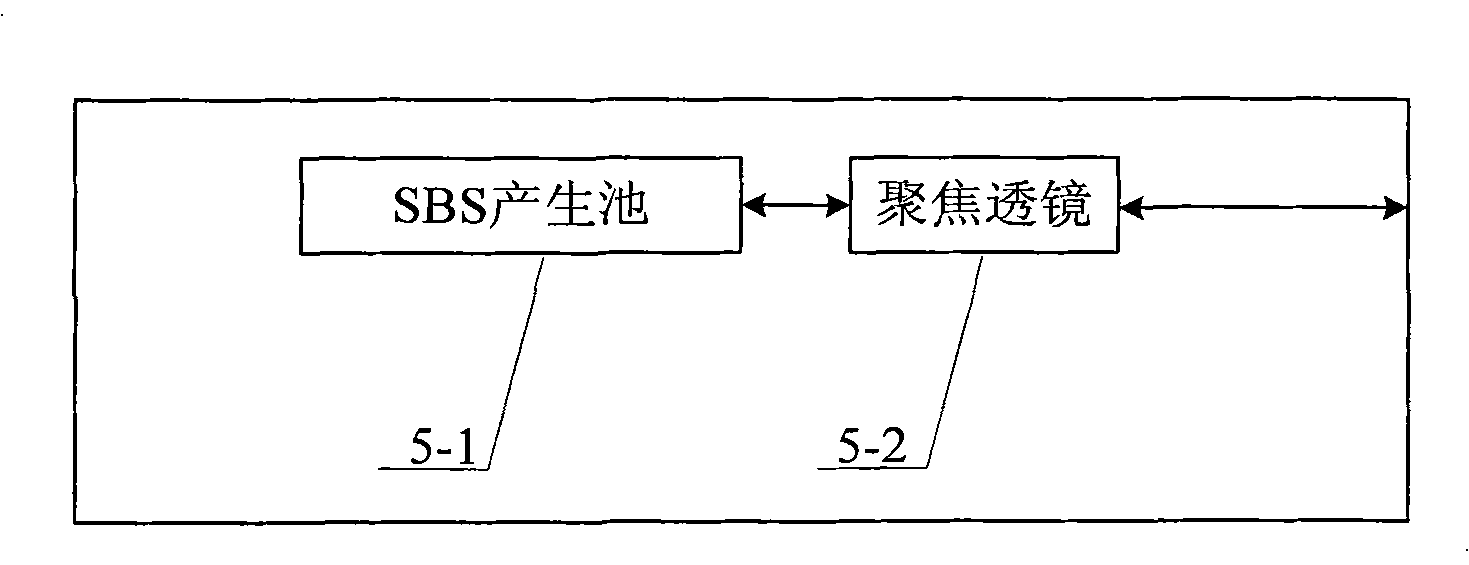

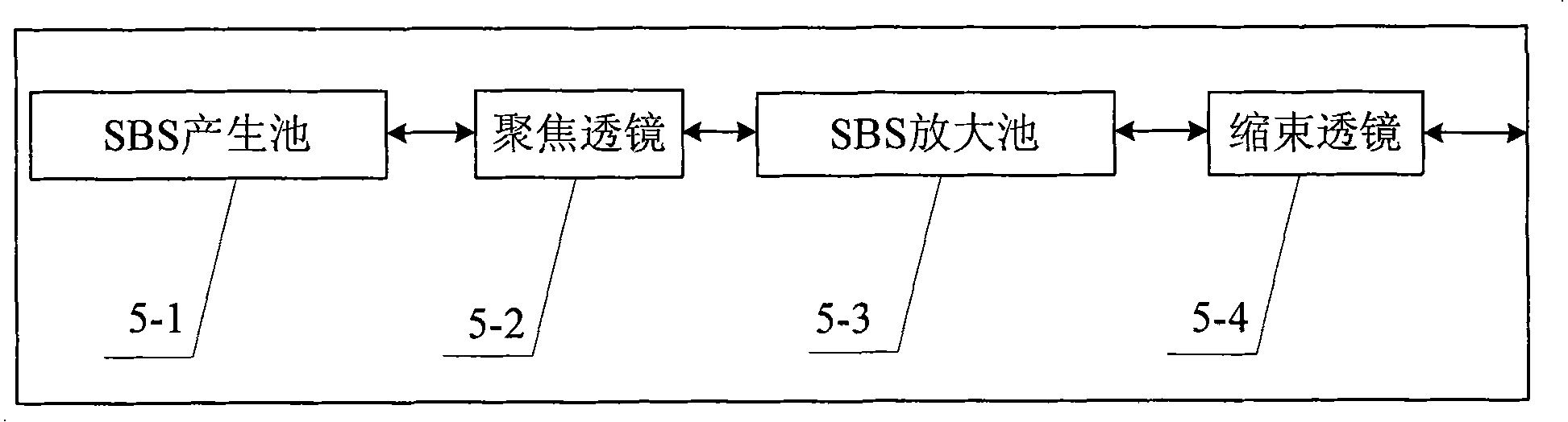

Modulation-eliminating stimulated Brillouin scattering laser pulse compression apparatus

InactiveCN101504505AGuaranteed compression ratioImprove waveform qualityNon-linear opticsEnergy regulationIsolated system

The invention provides a modulation-eliminating stimulated Brillouin scattering (SBS) laser impulse compression device, which relates to a device for obtaining modulation-free narrow impulse waveforms, and overcomes the defects that the output waveforms of an SBS impulse compression system in the prior art have poor quality, are unstable and are accompanied with modulation phenomenon. A Pump laser impulse is emitted by a laser light source and enters a first-stage compression system after passing through a first half-wave plate, a first polaroid and a first quarter-wave plate, wherein the first Polaroid and the first half-wave plate form an energy regulating system, and the first polaroid and the first quarter-wave plate form an isolated system; and the Pump laser impulse returns to the first polaroid along the same path and is driven into a reflecting mirror by the first polaroid, and the connections of the light paths of the reflecting mirror reflects the light to a second half-wave plate, wherein the second half-wave plate, a second polaroid, a second quarter-wave plate and a second-stage compression system are same as those of the light paths of the first half-wave plate, the first polaroid, the first quarter-wave plate and the first-stage compression system, and the output end of the second polaroid is a pulsed light output end. The modulation-eliminating stimulated Brillouin scattering laser impulse compression device is mainly applied to the energy level transition of a medium material of an optical pump research in spectroscopy.

Owner:HARBIN INST OF TECH

Production method of ultra-thick low-alloy steel plate

InactiveCN105256218AImprove cleanlinessGreat Physical Quality PerformanceChemical compositionSheet steel

The invention discloses a production method of an ultra-thick low-alloy steel plate. The process route adopted in the production method comprises smelting with a converter, LF refining, vacuum refining, mold casting, heating, rolling, slow cooling, heat treatment and shape correction. The ultra-thick low-alloy steel plate comprises the following chemical components in percentage by weight: 0.12-0.18% of C, 0.20-0.50% of Si, 1.30-1.60% of Mn, P of which the percentage is smaller than or equal to 0.015%, S of which the percentage is smaller than or equal to 0.005%, Als of which the percentage is smaller than or equal to 0.020-0.050%, 0.02-0.04% of Nb, 0.02-0.05% of V, 0.01-0.02% of Ti, and the balance being Fe and residual elements. According to the production method disclosed by the invention, a large-section cast ingot is adopted; in the aspect of component selection, a low-cost chemical component design only employing alloys of Nb, V and Ti is adopted; through an LF technology and a VD technology, the cleanliness of the steel plate is guaranteed; through controlled rolling and normalizing treatment, the grain size of steel can reach above 7.0 grade. The produced ultra-thick low-alloy steel plate has the characteristics that the thickness is 250mm; the crack detection property, the mechanical property and the plate shape can be guaranteed; the yield strength margin is 20-40Mpa; the tensile strength margin is 20-30Mpa; the elongation rate margin is 6%-9%; the impact resistance is uniform; the produced steel plate is particularly suitable for bases of wind driven generators.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

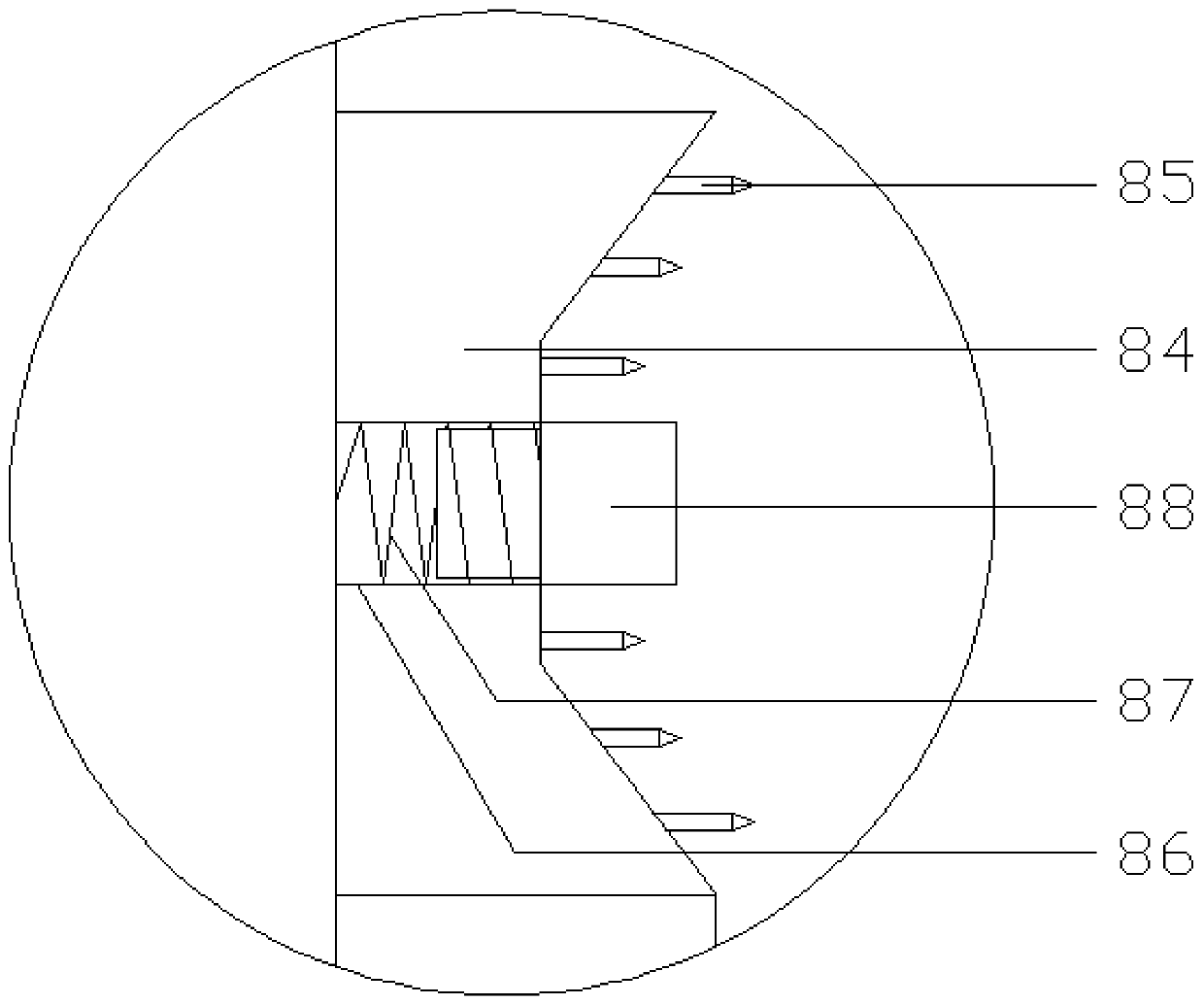

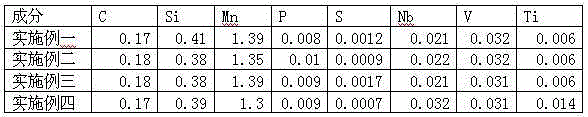

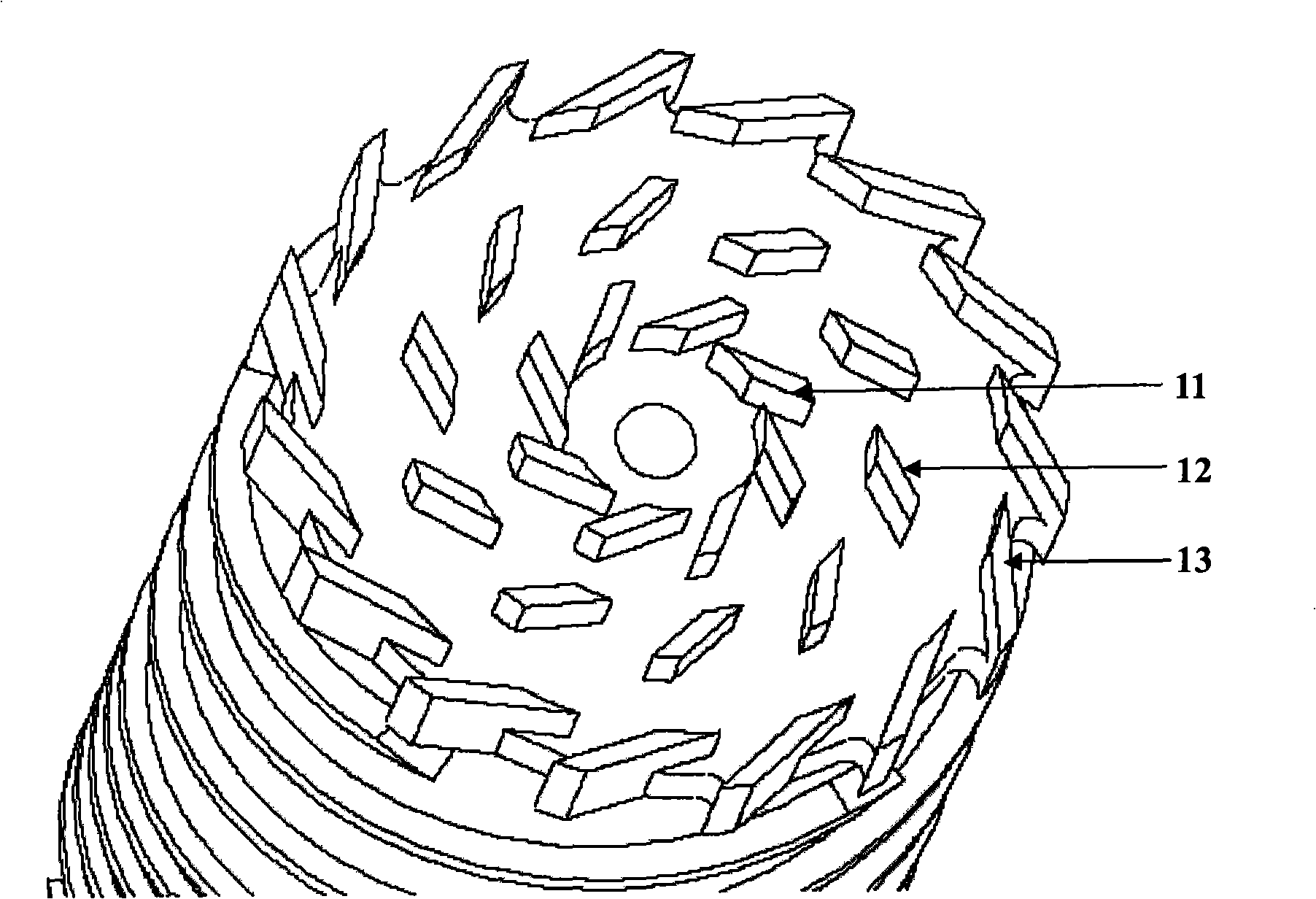

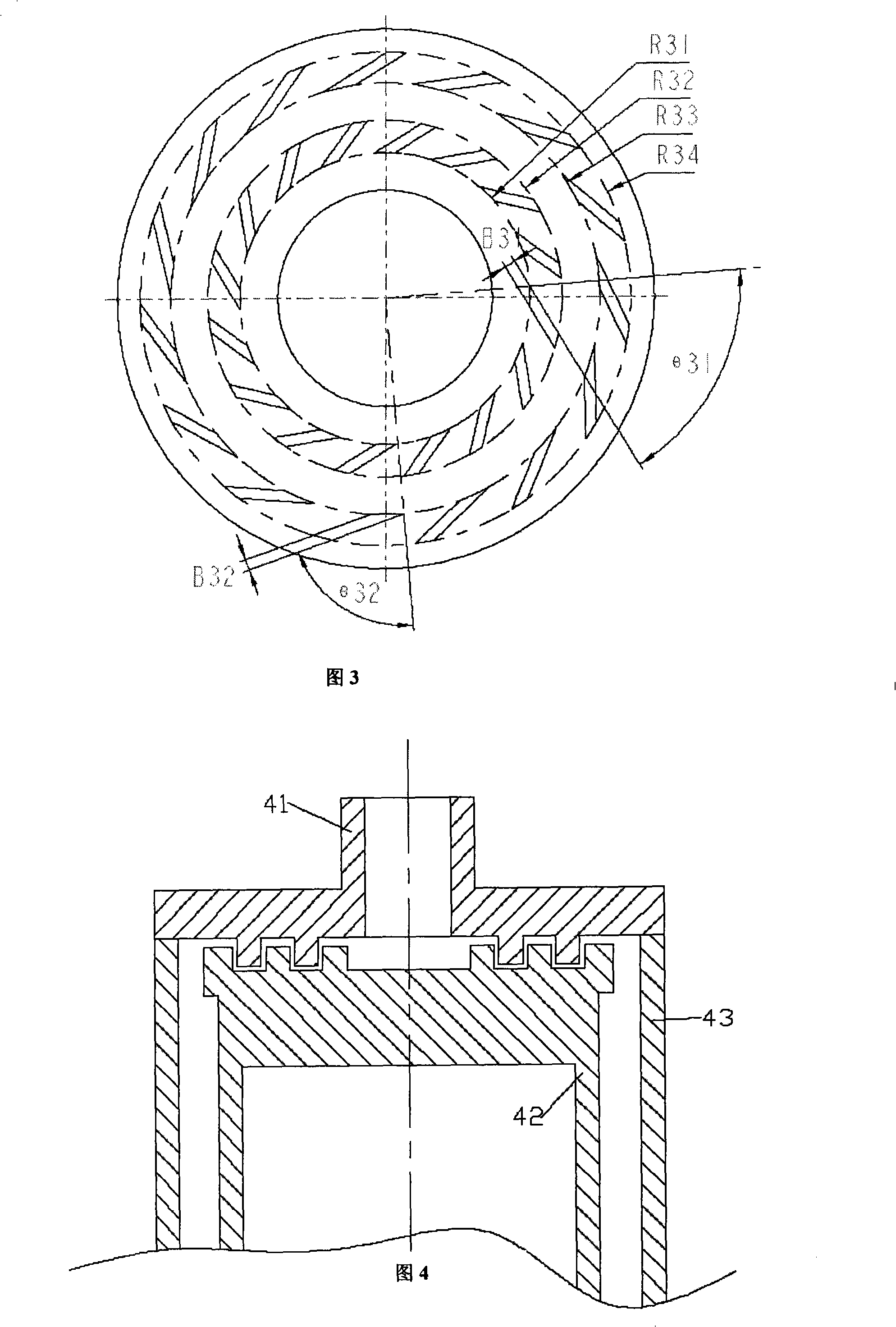

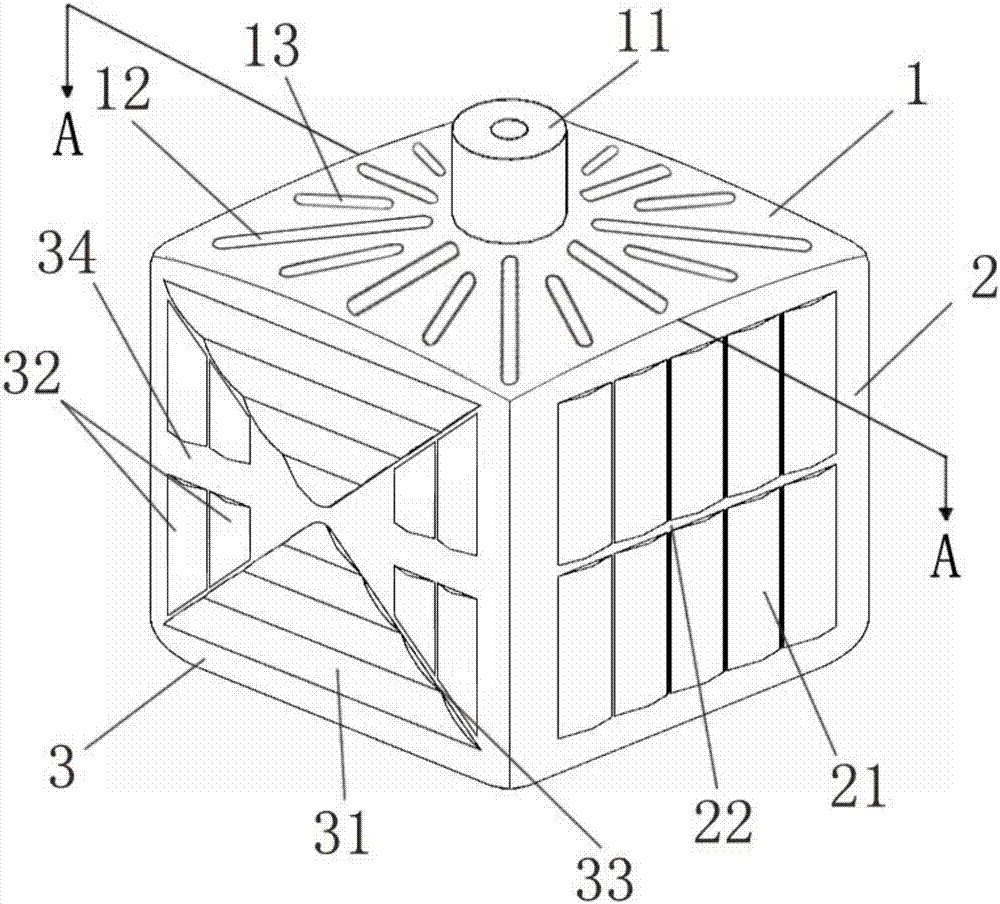

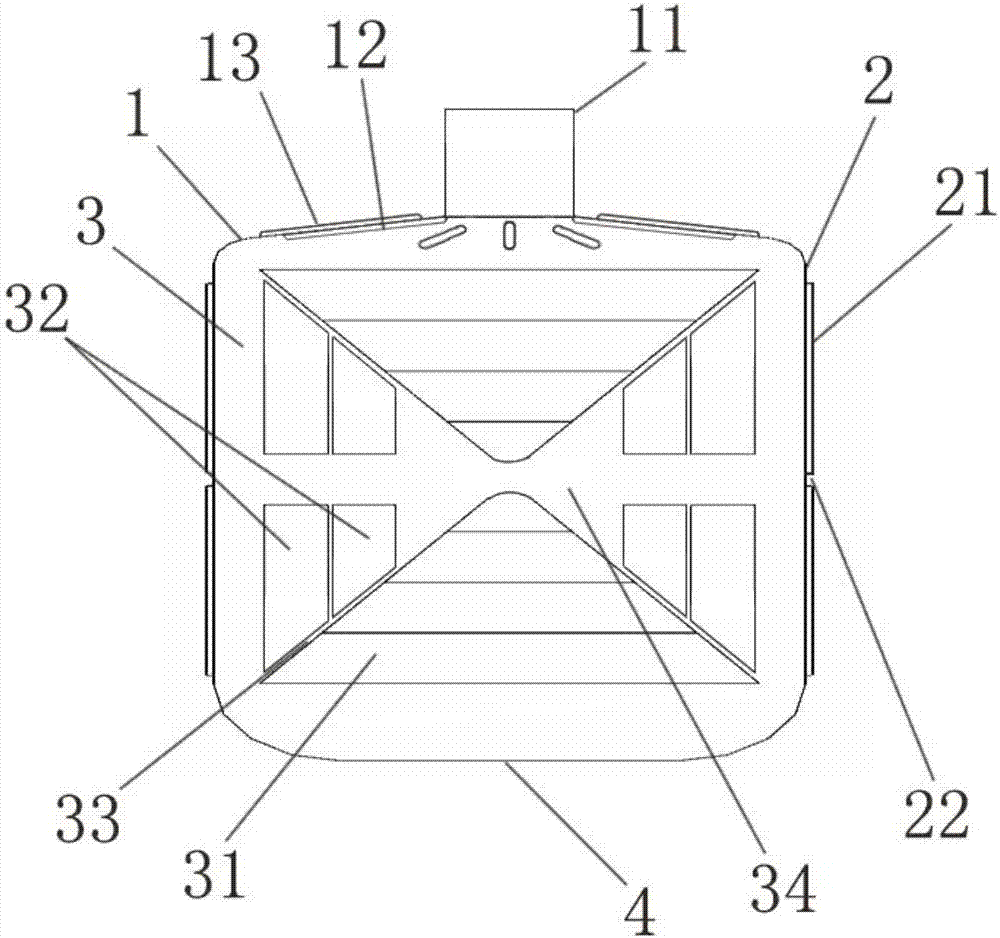

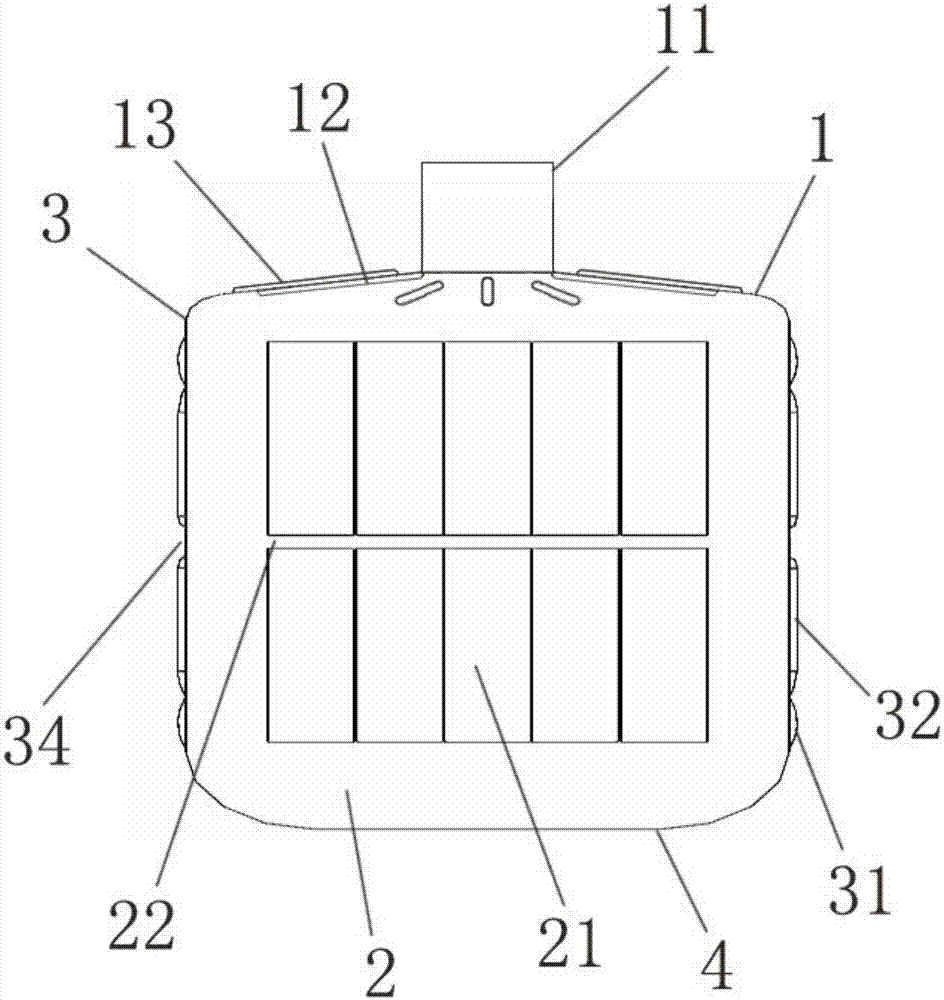

Miniature molecular pump utilizing leaf disc rotor

InactiveCN101403388AIncrease pumping speedEnhanced pre-stage pressure resistancePump componentsAxial flow pumpsEngineeringCantilever

The invention relates to the improvement of the rotor structure of a small molecular pump and enables the top face of a rotor to increase layers of moving blades (usually 1-3 layers) from the inside to the outside, which take the shape of radial upwards and being vertical to top surfaces and is shown as the following graph structure: the part provided with a spiral groove is a Holweck rotor which rotates at a high speed; on the top of the Holweck rotor, a first stage moving blade has the smallest radius, a third stage moving blade has the largest radius, and a second stage moving blade is in the middle. Part of the third stage moving blade is vertical to the top surface in the internal part thereof; part of the third stage moving blade extends out of the top surface and is a cantilever structure. The part of the moving blade which extends outside extends downwards, with the extending height larger than the moving blade in the internal part of the top surface; the blade on a tectum static blade disc is a second stage static blade and is turned over for being inserted among the rotor blades, thereby forming a fifth stage pumping structure so as to improve the pumping speed of molecular pumps.

Owner:KYKY TECH

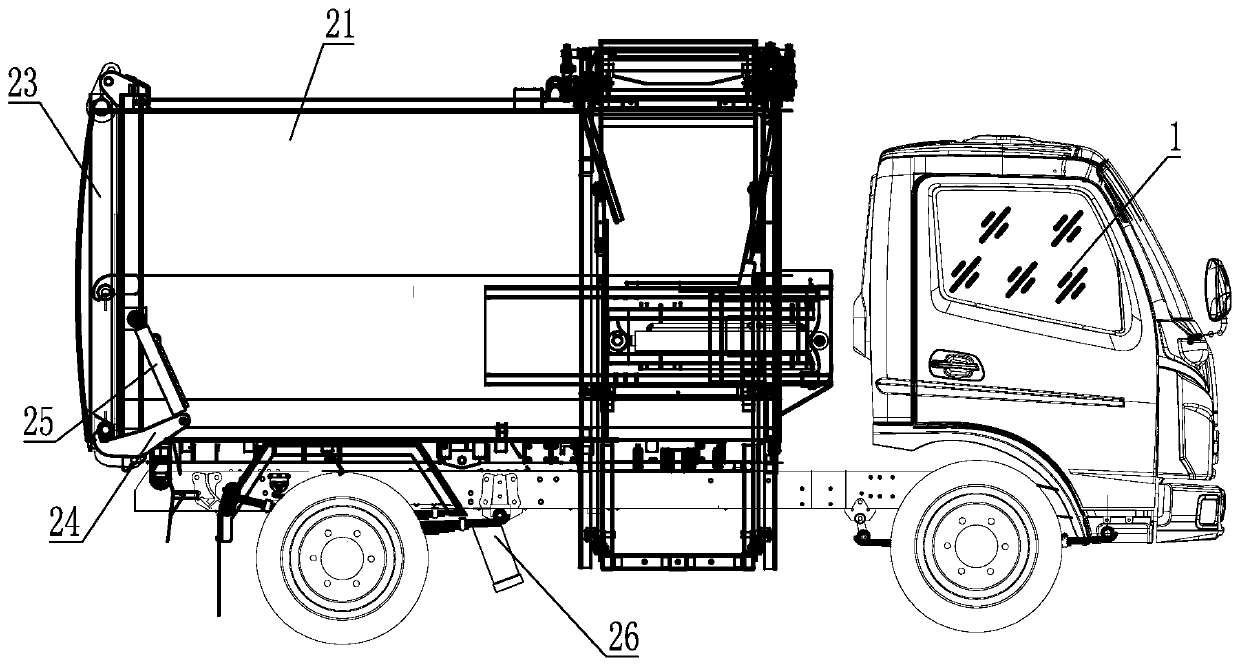

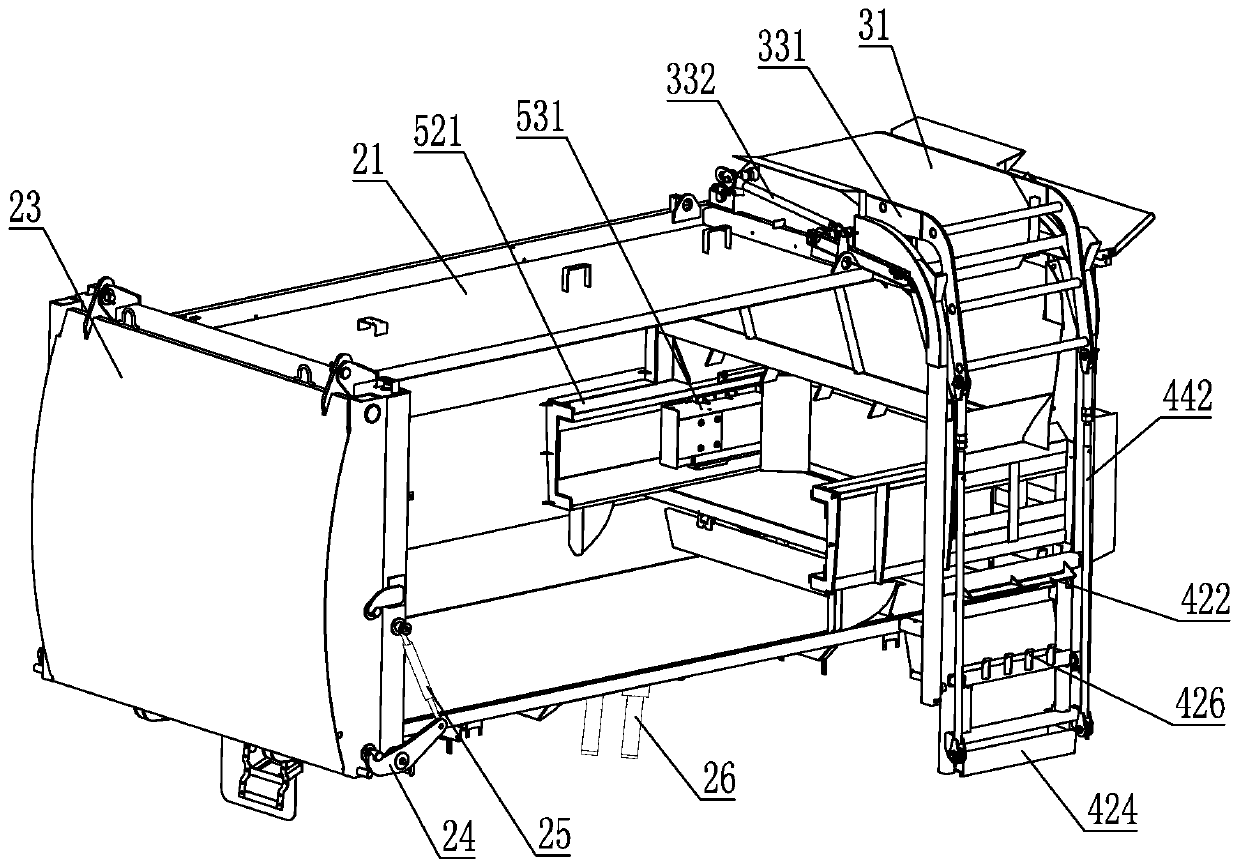

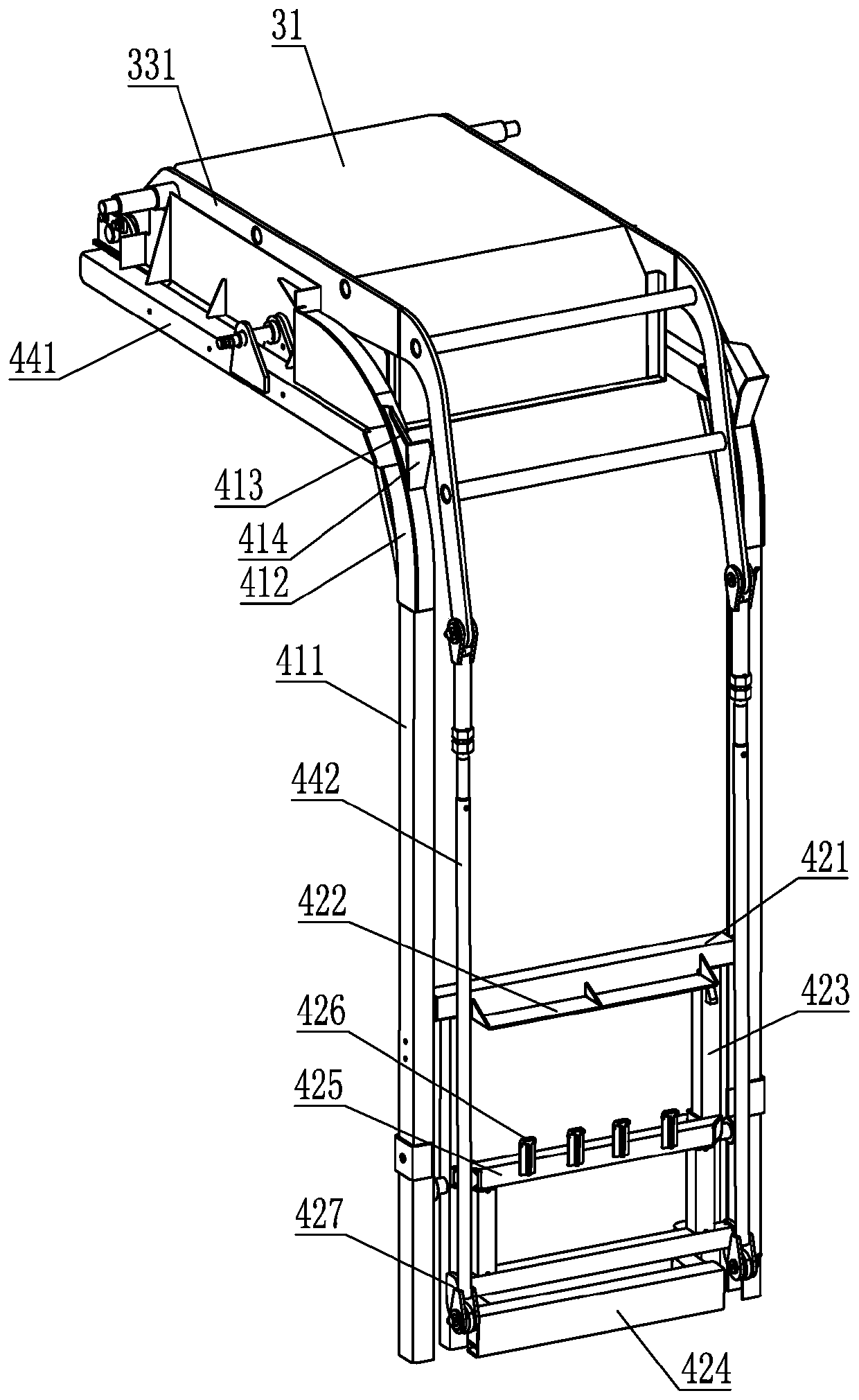

Novel side-mounted pressing vehicle

PendingCN110697299AGuaranteed processing efficiencyReduce manufacturing costRefuse vehiclesPressesEngineeringTruck

The invention discloses a novel side-mounted pressing vehicle. The novel side-mounted pressing vehicle comprises a second-class chassis and a transfer box. A garbage feeding port is arranged at the top end of the transfer box. A cover plate used for sealing the garbage feeding port is rotatably arranged on the transfer box. A garbage dividing device is mounted on one side, facing the interior of the transfer box, of the cover plate. A barrel lifting device is mounted on the outer side wall of the transfer box and on one side of the garbage feeding port. A rotating driving device used for driving the cover plate to be opened and closed is mounted on the transfer box and also serves as a barrel lifting power device of the barrel lifting device. A garbage pressing mechanism is mounted in thetransfer box and below the garbage feeding port. Compared with a traditional rear-mounted pressing vehicle, the side-mounted pressing vehicle is characterized in that the bucket lifting device is located on one side of a vehicle body while the pressing ratio and the garbage truck processing efficiency are guaranteed, the right side is preferred when driving on the right side is mentioned in a traffic rule, parking on the right side is okay during collection work, the convenience is improved, the operation efficiency is higher, and the production cost of the whole vehicle is relatively lower.

Owner:山东五征环保科技股份有限公司

Water dispenser bucket

InactiveCN106976621AGuaranteed Compression RatioAnti-bending effectRigid containersStructural engineeringEngineering

Owner:田谊

Steel for saw blade and its production method

ActiveCN104498840BReasonable ingredient controlImprove performanceChemical compositionSmelting process

Owner:INNER MONGOLIA BAOTOU STEEL UNION

12Cr2Mo1R steel plate for ultra-thick hydrogen-contacting equipment and production method thereof

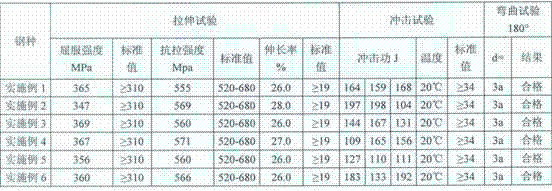

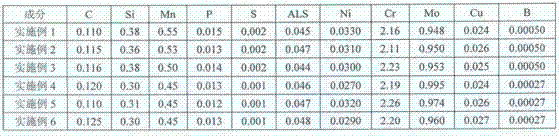

The invention discloses a 12Cr2Mo1R steel plate for ultra-thick hydrogen-contacting equipment and a production method thereof. The 12Cr2Mo1R steel plate comprises the following chemical components, by mass, 0.08-0.15% of C, 0.20-0.50% of Si, 0.30-0.60% of Mn, equal to or less than 0.018% of P, equal to or less than 0.005% of S, equal to or less than 0.020-0.050% of AlS, 2.0-2.5% of Cr, 0.90-1.10% of Mo, and the balance Fe and residual elements. The production method comprises steps of converter smelting, LF refining, vacuum refining, casting, heating, rolling, controlled cooling, slow cooling, and heat processing. A whole production process from molten iron pretreatment to steel plate heat treatment is executed in strict accordance with above technology, so the object quality performance margin of products is large, wherein the yield margin is 40-80Mpa, the tensile margin is 55-70Mpa, and the elongation margin is 6-9%, thereby the impact performance is uniform and the margin is large.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

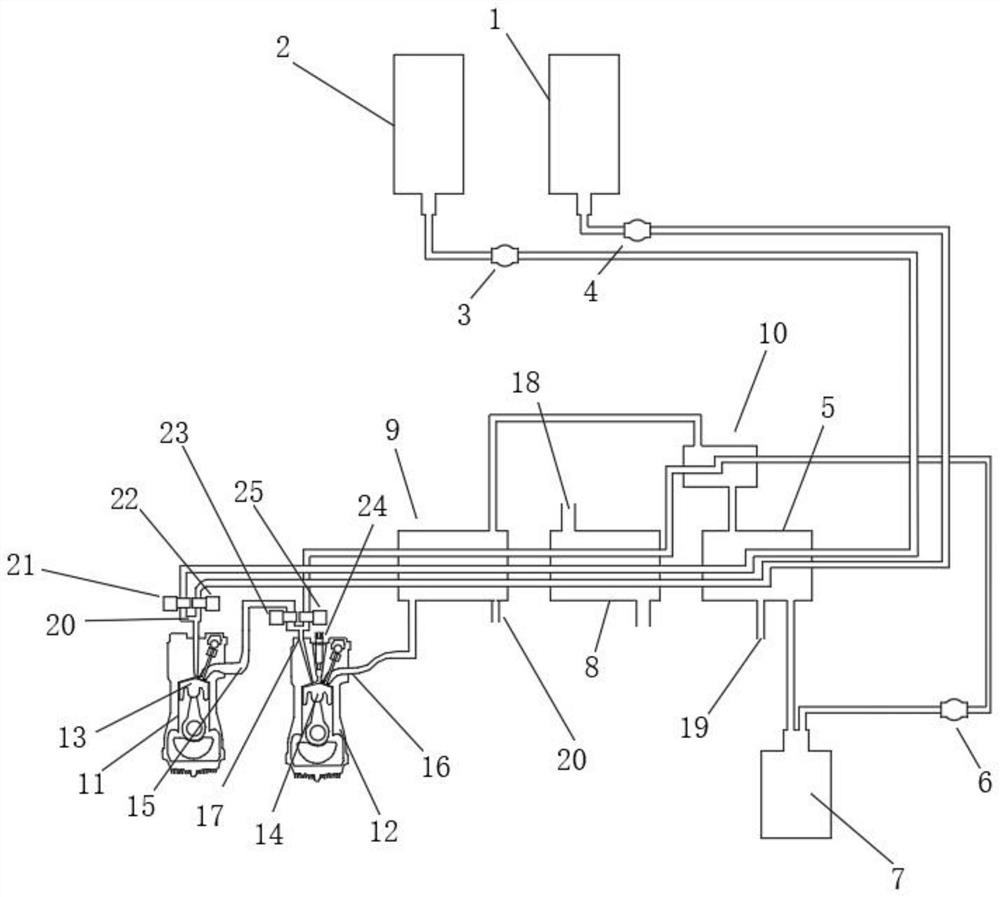

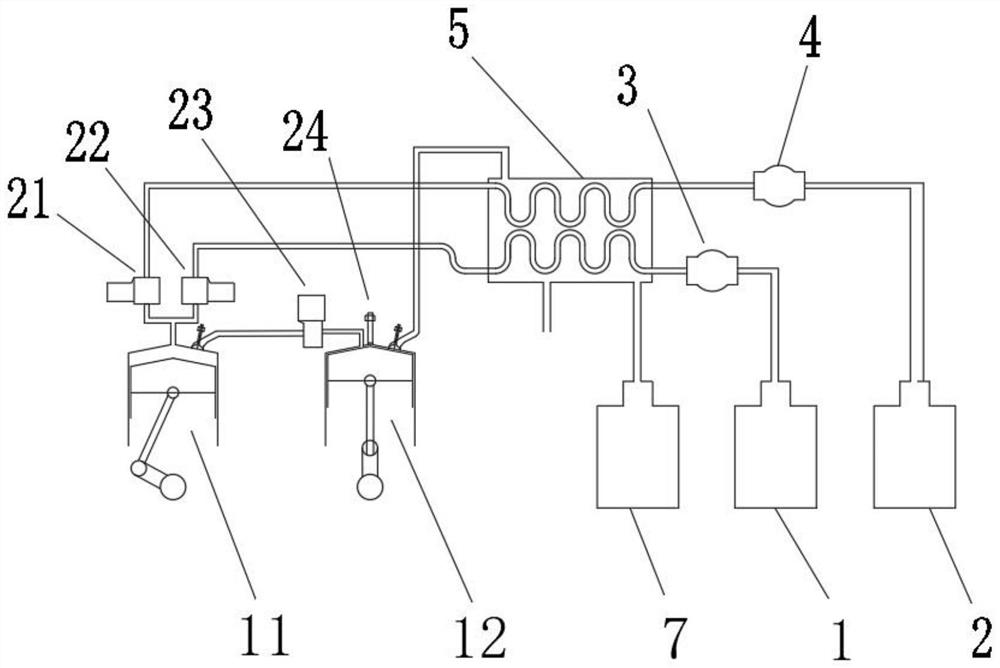

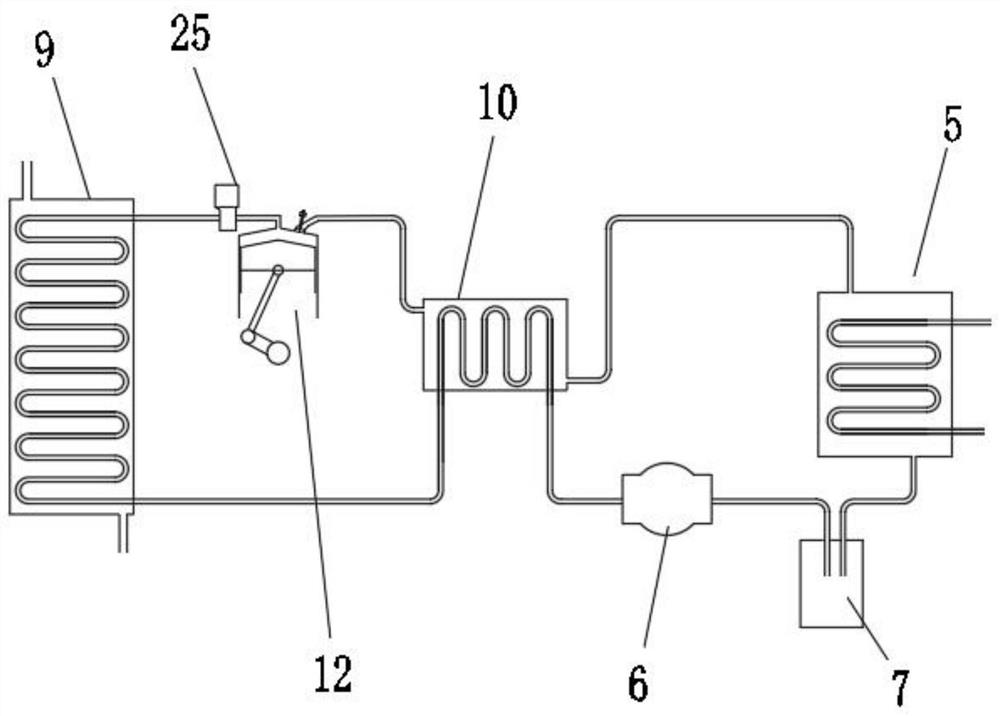

High and low temperature combined cycle engine

ActiveCN110645051ACombustion component is singleBurn fullyReciprocating combination enginesInternal combustion piston enginesAutomotive engineeringZero emission

The invention discloses a high and low temperature combined cycle engine comprising a fuel tank, an oxidant tank, a first heat exchanger, a liquid carbon dioxide tank, a second heat exchanger, a thirdheat exchanger, a first cylinder and a second cylinder. A first piston is installed in the first cylinder. A second piston and a sparking plug are installed in the second cylinder. A gas inlet is fixedly connected to the top end of the first cylinder. A second gas inlet is fixedly connected to the top end of the second cylinder. A second cryogenic pump and a first cryogenic pump are connected tothe output ends of the fuel tank and the oxidant tank correspondingly. According to the high and low temperature combined cycle engine, liquid oxygen is adopted as an oxidant to replace air, burning components are simple, burning is more sufficient, zero emission can be achieved, the high and low temperature combined cycle engine can work in an environment without air, higher pressure and temperature are generated after burning, and engine efficiency is improved. Meanwhile, emission of nitrogen oxide, carbon monoxide and other harmful gases is reduced.

Owner:施爱龙

Refrigeration control method, device and air conditioner

ActiveCN105333563BIncreased likelihood of normal workGuaranteed compression ratioMechanical apparatusSpace heating and ventilation safety systemsTemperature controlLower limit

The embodiment of the invention discloses a refrigeration control method and device and an air conditioner and relates to the technical field of temperature control. It can be guaranteed that on the basis of reliability of the air conditioner, low-temperature refrigeration of the air conditioner is achieved. According to the specific scheme, the current value of the outdoor environment temperature is acquired, when the current value of the outdoor environment temperature is higher than a first preset temperature and lower than a second preset temperature, a compressor of the air conditioner is controlled to run under the frequency within a first running frequency interval, and an outdoor unit fan of the air conditioner is controlled to run at a rotating speed within a first rotating speed interval; and the frequency lower limit value of the first running frequency interval and the rotating speed upper limit value of the first rotating speed interval are running frequency of the compressor and the rotating speed of the outdoor unit fan respectively when the air conditioner performs refrigeration at the first preset temperature and the compression ratio of the compressor is at least the recommended compression ratio. The refrigeration control method and device are used in the temperature adjusting process of the air conditioner.

Owner:广东科龙嘉科电子有限公司

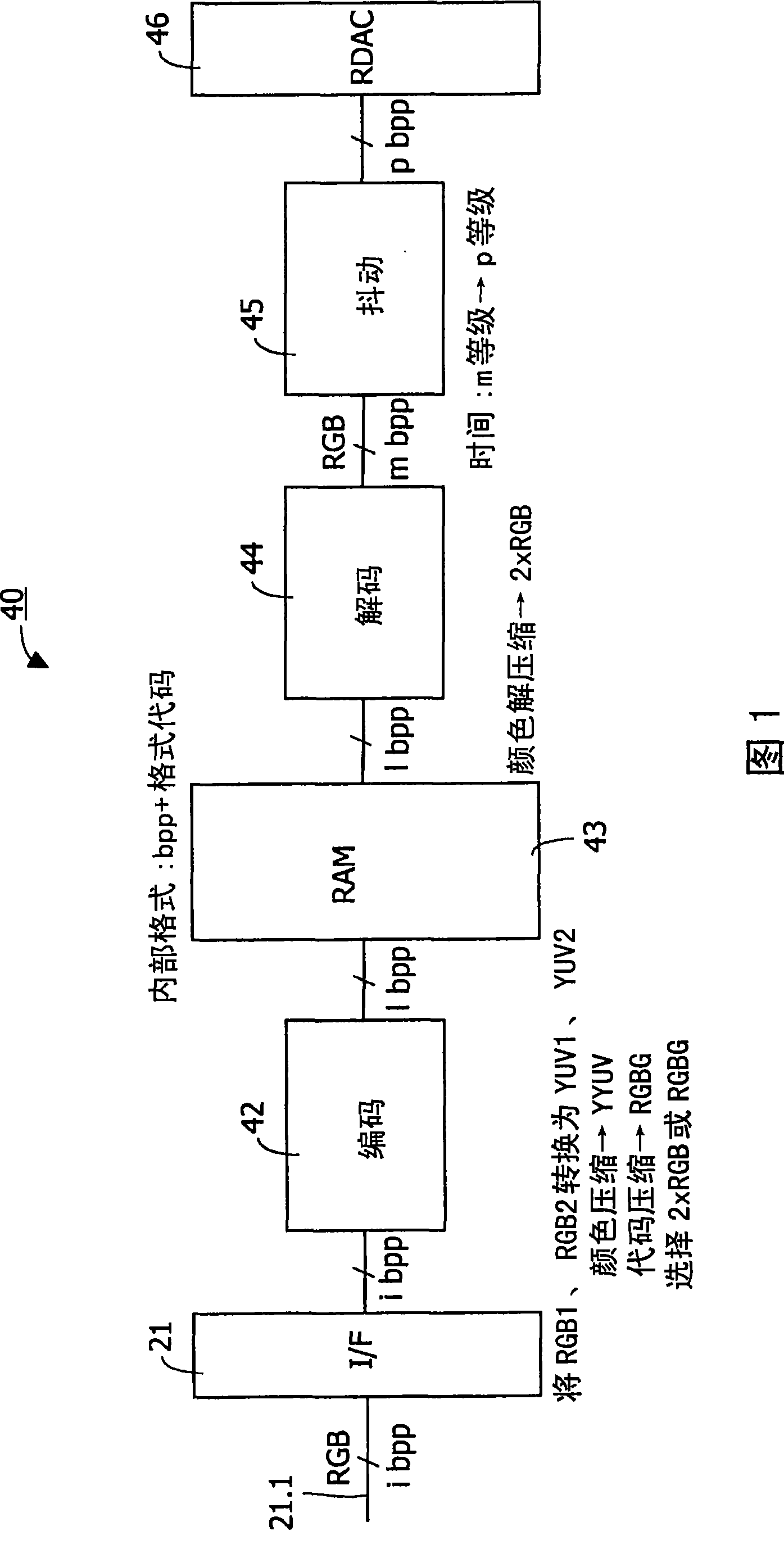

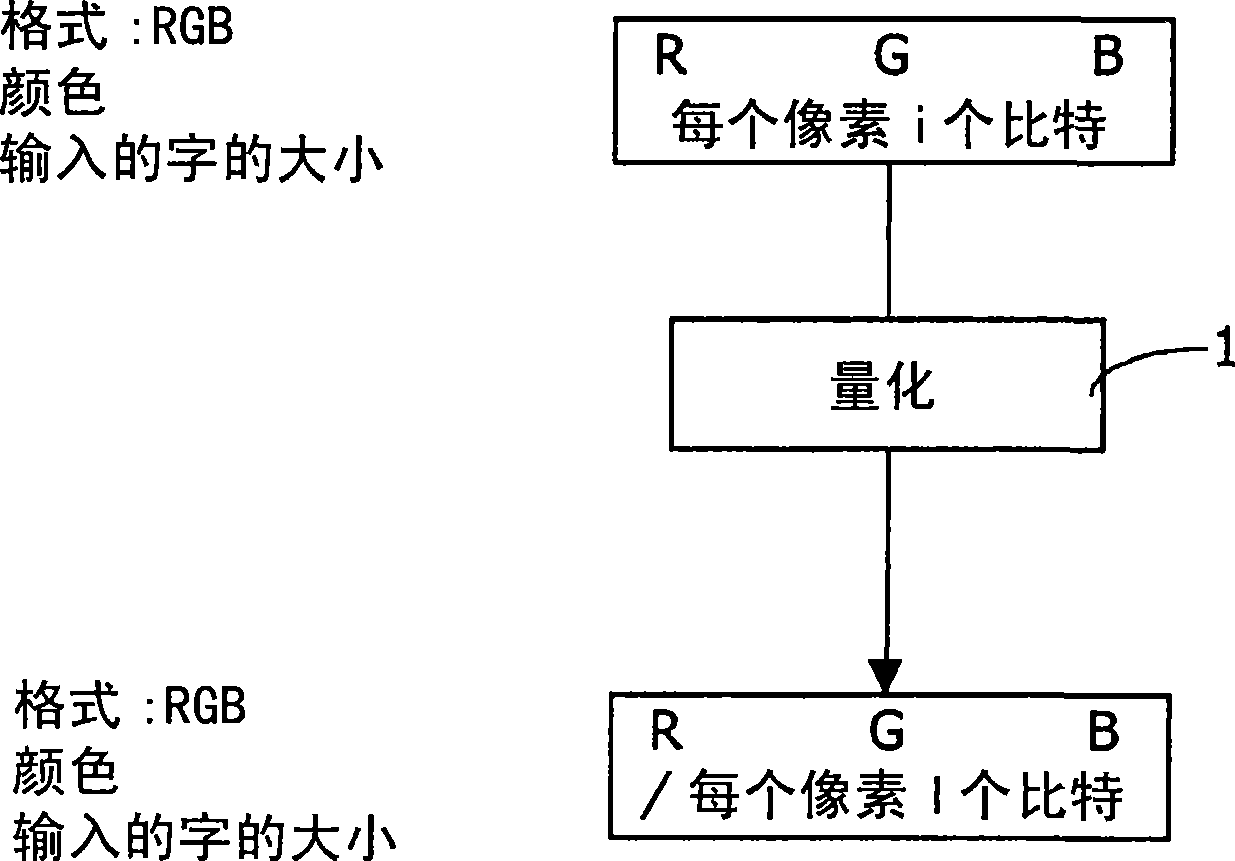

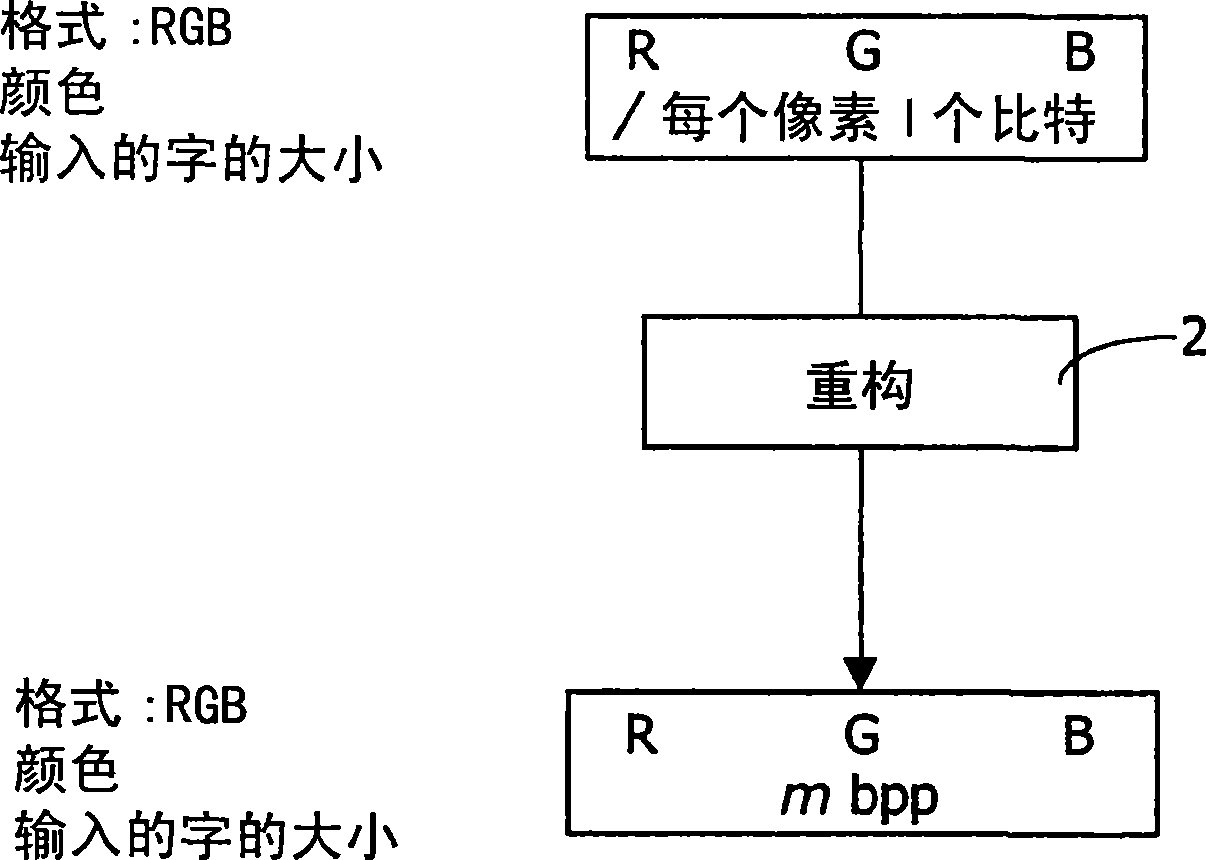

New compression format and apparatus using the new compression format for temporarily storing image data in a frame memory

InactiveCN101142821BIncrease the number ofImprove performanceImage codingCathode-ray tube indicatorsColor imageImaging data

Owner:NXP BV

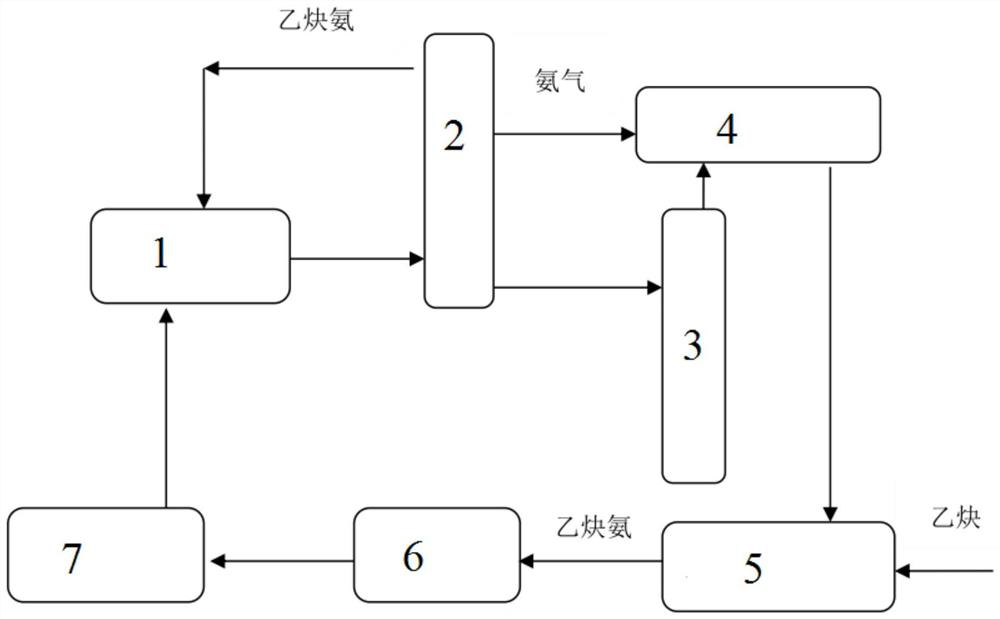

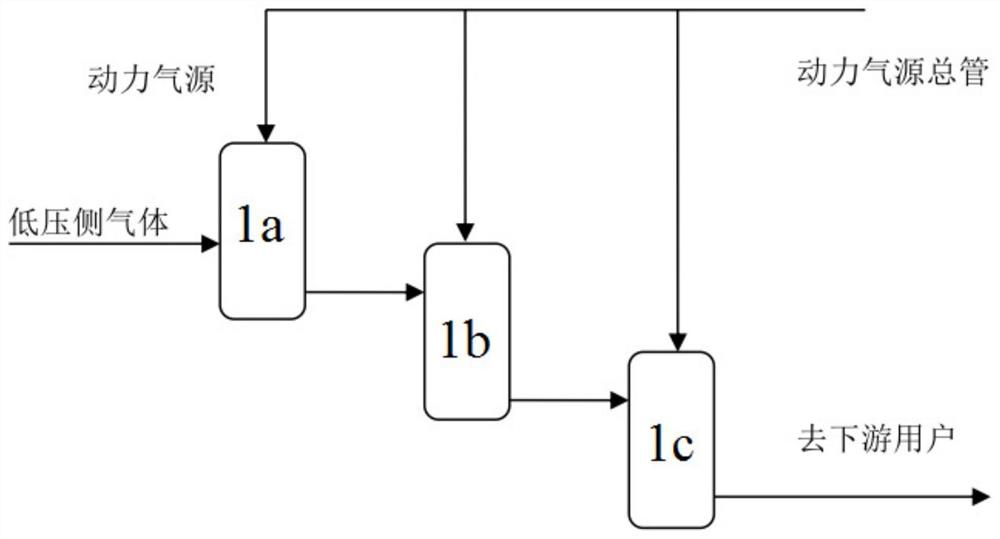

Energy-saving process for acetylenic ketone reaction device

PendingCN113248348AAnti-channelingIncrease intake pressureOrganic compound preparationChemical industryKetoneProcess engineering

The invention provides an energy-saving process for an acetylenic ketone reaction device. Pressurized rectification and normal-pressure rectification are sequentially carried out on an output material flow of an acetylenic ketone reactor so as to remove acetylene and ammonia in a reaction product, and low-pressure ammonia gas (100-2000 Pa) generated by a normal-pressure rectifying tower is drained by utilizing high-pressure ammonia gas (1.2-1.5 MPaG) extracted from a side line of a pressurized rectifying tower, so after ammonia gas generated by rectification of the normal-pressure rectifying tower is input into the first-stage pressure raiser, the gas pressure is increased; and then mixed ammonia gas output by the first-stage pressure raiser is used for guiding low-pressure acetylene, so that the pressure of acetylene and ammonia mixed gas output by the second-stage pressure raiser is increased to a relatively high degree, the inlet pressure of the compressor is increased, and the compression ratio of the compressor is greatly reduced. Specifically, the compression ratio is reduced from 30 to 6-8, energy is saved by 55% compared with that of a pressurized rectification process, and energy is saved by more than 80% compared with that of flash evaporation.

Owner:四川丰雍科技有限公司

Near-lossless real-time compression method for satellite-borne hyper-spectral interference fringe image

ActiveCN101576412BHigh speedLarge distortion rateInterferometric spectrometryImage codingTreatment differenceUniform quantization

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Modulation-eliminating stimulated Brillouin scattering laser pulse compression apparatus

InactiveCN101504505BGuaranteed compression ratioImprove waveform qualityNon-linear opticsIsolated systemEnergy regulation

The invention provides a modulation-eliminating stimulated Brillouin scattering (SBS) laser impulse compression device, which relates to a device for obtaining modulation-free narrow impulse waveforms, and overcomes the defects that the output waveforms of an SBS impulse compression system in the prior art have poor quality, are unstable and are accompanied with modulation phenomenon. A Pump laser impulse is emitted by a laser light source and enters a first-stage compression system after passing through a first half-wave plate, a first polaroid and a first quarter-wave plate, wherein the first Polaroid and the first half-wave plate form an energy regulating system, and the first polaroid and the first quarter-wave plate form an isolated system; and the Pump laser impulse returns to the first polaroid along the same path and is driven into a reflecting mirror by the first polaroid, and the connections of the light paths of the reflecting mirror reflects the light to a second half-waveplate, wherein the second half-wave plate, a second polaroid, a second quarter-wave plate and a second-stage compression system are same as those of the light paths of the first half-wave plate, the first polaroid, the first quarter-wave plate and the first-stage compression system, and the output end of the second polaroid is a pulsed light output end. The modulation-eliminating stimulated Brillouin scattering laser impulse compression device is mainly applied to the energy level transition of a medium material of an optical pump research in spectroscopy.

Owner:HARBIN INST OF TECH

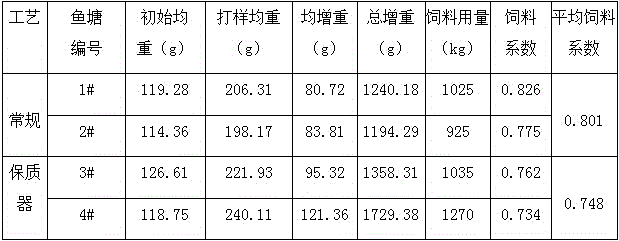

A kind of production technology of tilapia pellet feed

ActiveCN104997144BImprove palatabilityImprove conditioning environmentFeeding-stuffQuenchingOreochromis mossambicus

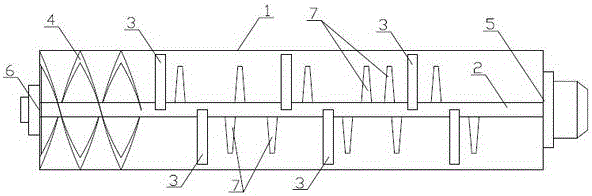

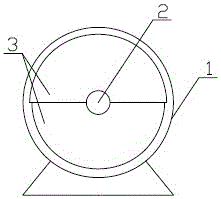

The present invention relates to production technology of oreochromis mossambicus granulated feed, and belongs to the technical field of fish feed. The production technology includes: conducting an initial quenching and high temperature tempering treatment on raw materials of oreochromis mossambicus feed with a first conditioner, continually conducting a material curing guaranteeing treatment on the raw materials for 130-150 seconds with a material curing guaranteeing device, conducting secondary quenching and high temperature tempering treatment on the raw materials with a second conditioner, and finally placing the raw materials into a granulator, thereby obtaining the oreochromis mossambicus granulated feed. The production technology can not only improve the material quenching and high temperature tempering environment, but also reduce the ring die compression ratio of the granulator in the subsequent granulating process, so that the production technology can not only guarantee product uniformity, water resistance and powder containing ratio requirements, but also improve the production efficiency and the palatability of fish feed.

Owner:JIEYANG TONGWEI FEED

High and low temperature combined cycle engine

ActiveCN110645051BGuaranteed compression ratioResize freelyReciprocating combination enginesInternal combustion piston enginesEngine efficiencyFuel tank

The invention discloses a high and low temperature combined cycle engine, comprising a fuel tank, an oxidant tank, a first heat exchanger, a liquid carbon dioxide tank, a second heat exchanger, a third heat exchanger, a first cylinder and a second cylinder, the first A first piston is installed inside a cylinder, a second piston and a spark plug are installed inside the second cylinder, an air inlet is fixedly connected to the top of the first cylinder, and a second piston is fixedly connected to the top of the second cylinder. Two air inlets, the output ends of the fuel tank and the oxidizer tank are respectively connected with the second cryopump and the first cryopump. The high-low temperature combined cycle engine uses liquid oxygen instead of air as the oxidant, the combustion component is single, the combustion is more complete, zero emissions can be achieved, and it can work in an air-free environment, and the combustion generates higher pressure and temperature, which improves the engine efficiency. At the same time, it reduces the emission of harmful gases such as nitrogen oxides and carbon monoxide.

Owner:施爱龙

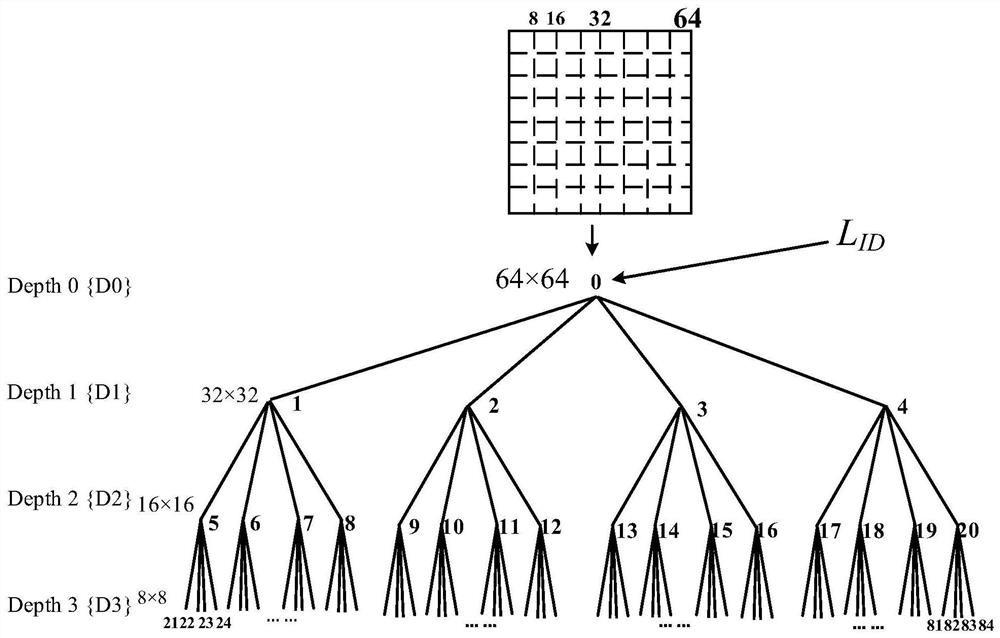

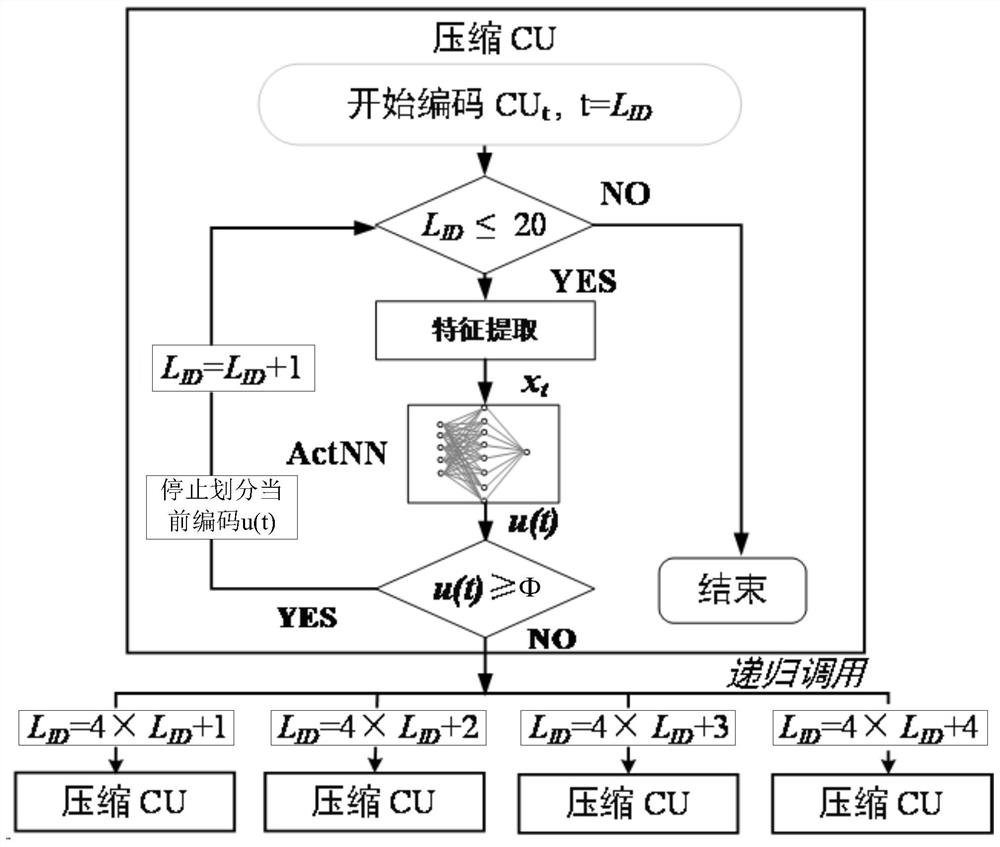

A low-complexity video signal coding and processing method

ActiveCN109769119BGuaranteed complexityReduce complexityDigital video signal modificationFeature vectorDecision maker

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

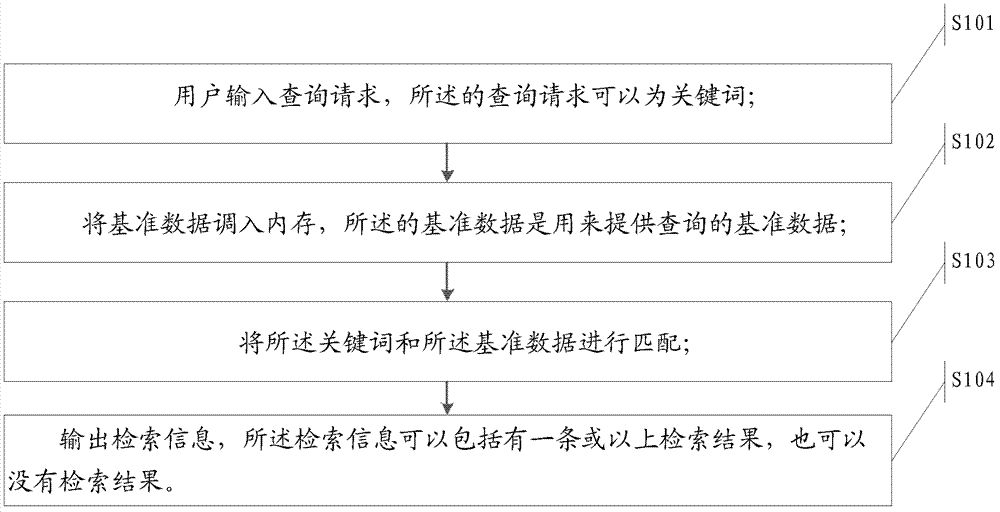

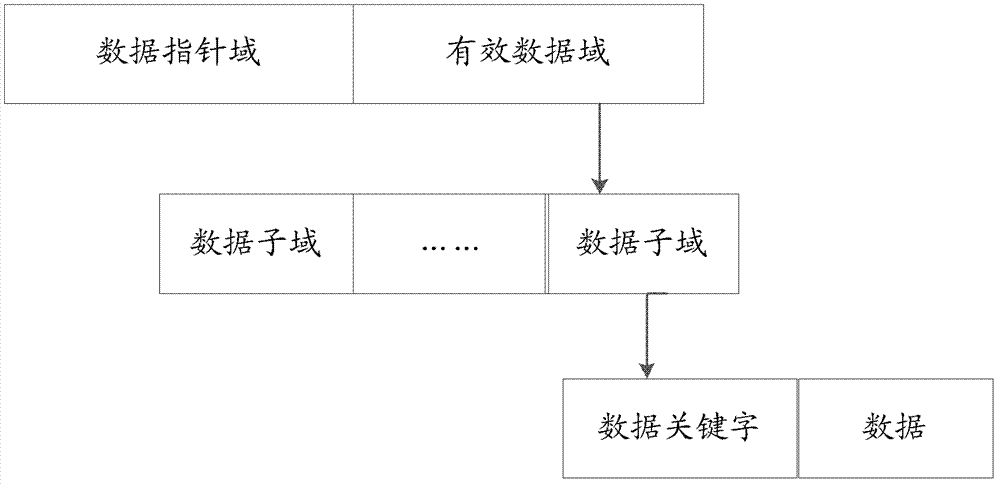

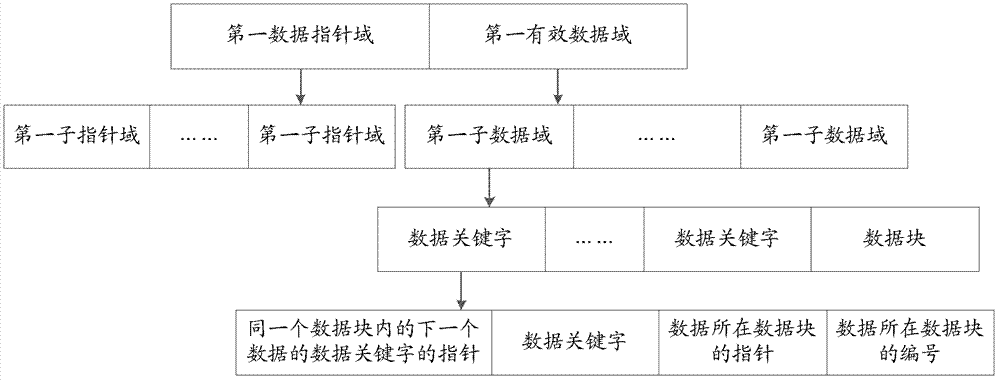

Method and system for realizing data storage and search

ActiveCN103034649BReduce memory overheadConsidering query efficiencySpecial data processing applicationsData domainData field

The invention discloses a method and a system for realizing data storage and search. The method for storing data comprises the following steps: acquiring a data block to be stored, wherein the data block comprises at least one piece of data; compressing the data block into a compressed data block; and storing the data keyword and the compressed data block of each data into a first sub-data field of a first valid data field of a first data structure, wherein the first data structure comprises the first valid data field and a first data pointer field; the first valid data field comprises a plurality of first sub-data fields; each first sub-data field is used for storing the data keyword and the compressed data block of each piece of data in one data block; and the first data pointer field is used for storing a pointer for looking up the data keyword when the data is searched.

Owner:TAOBAO CHINA SOFTWARE

Pipe mold manufacturing process adopting continuous-casting blank to forge and roll rough blank periodically

InactiveCN102179681BHigh strengthHigh hardnessMetal rolling arrangementsStructure propertyManufacturing technology

The invention relates to a pipe mold manufacturing process adopting a continuous-casting blank to forge and roll a rough blank periodically, belonging to the technical field of pipe mold manufacture. The manufacturing process comprises the process steps of: smelting of the continuous casting blank in a blast furnace, reinspecting, blanking, heating in a ring-shaped furnace, mannesmann piercing, periodically rolling a pipe, straightening, detecting flaws with magnetic powder, cutting the head and the tail, roughly processing, boring, carrying out ultrasonic flaw detection, thermally treating, sampling and reinspecting, finish processing, carrying out surface strengthening treatment, inspecting, spraying and printing, weighing and warehousing. The pipe mold manufacturing process has the advantages that the continuous casting blank replaces the mold casting blank adopted by the existing process, the characteristics that the yield is high, the cost is low, the energy consumption is less, the structure property is stable and the like are fully exerted, and the cost is reduced in the two aspects of the process and raw materials; in addition, the forging and rolling of a Pilger type rolling machine and the structure characteristics of a classic T-shaped pipe mold are effectively combined, the condition that the pipe mold blank forged and rolled by the process periodically has the performance close to the forged blank of the traditional pipe mold is guaranteed, and the Pilger head which needs to be cut in rolling is fully utilized simultaneously, so that the production efficiency is improved greatly.

Owner:邯郸市鑫泽天然气科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com