Miniature molecular pump utilizing leaf disc rotor

A molecular pump and rotor technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, which can solve the problems of low pumping speed, reduced product reliability, and lack of blade structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

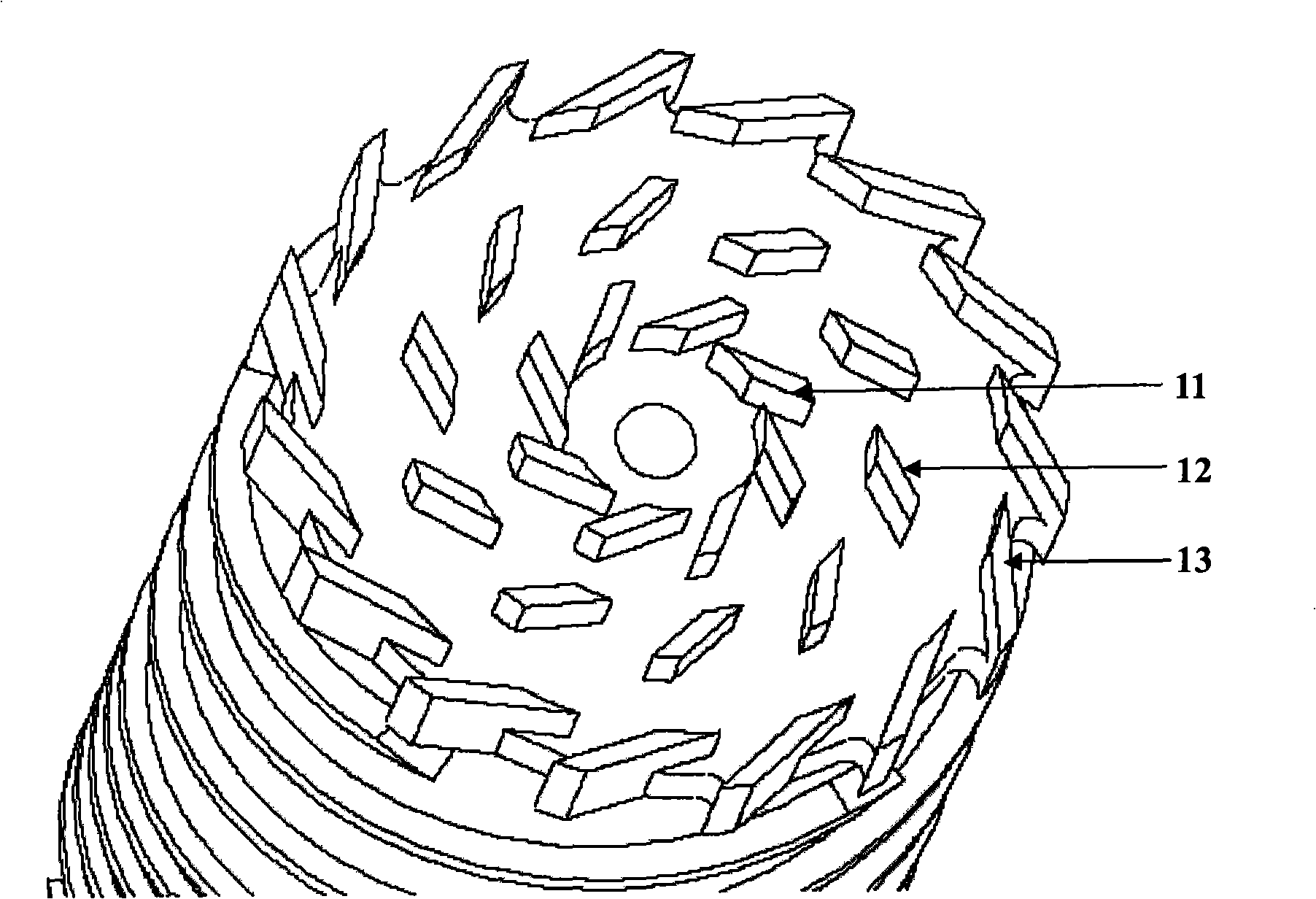

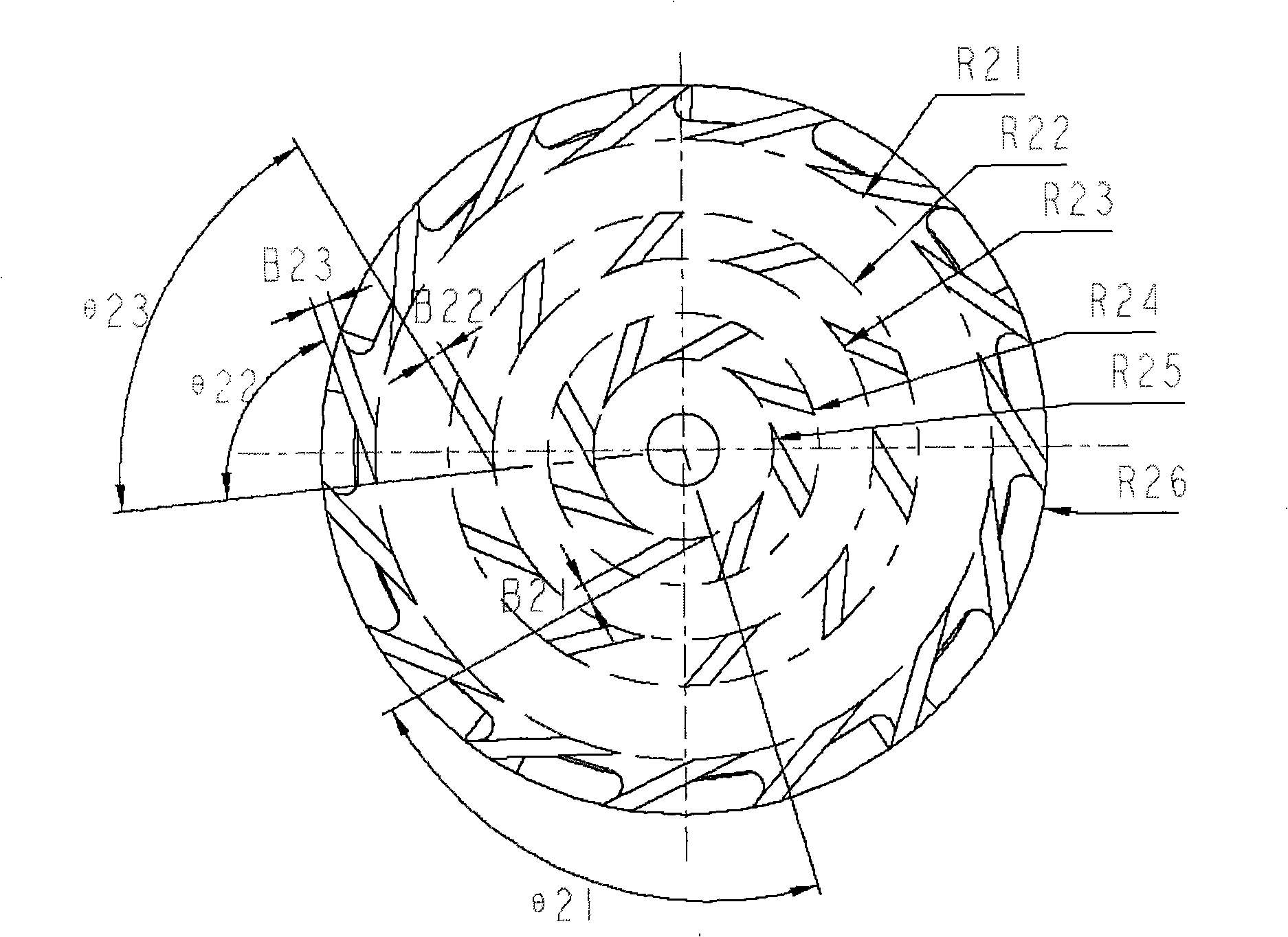

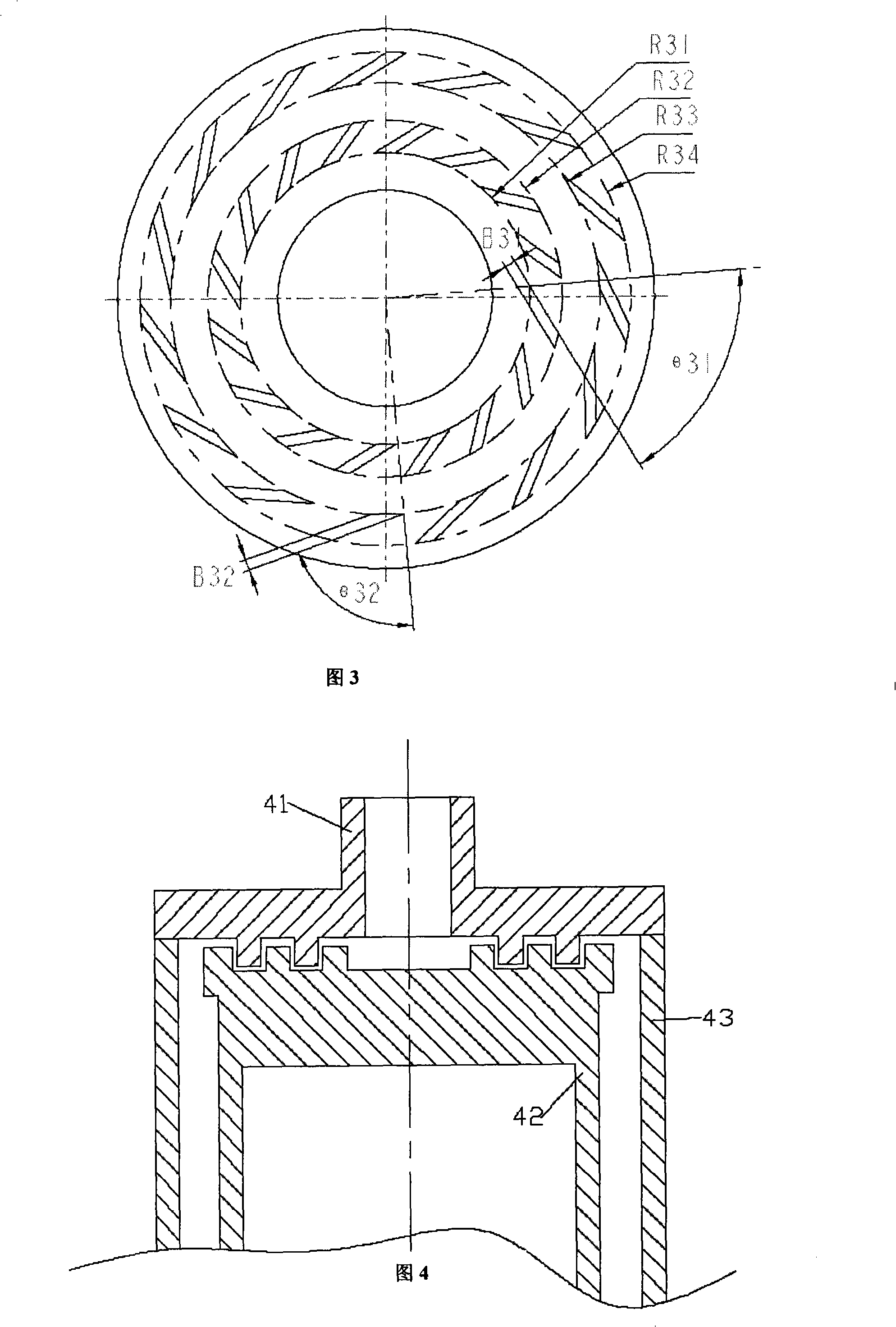

[0011] see figure 1 As shown in -4, the rotor provided by the present invention adds blades on the top surface of the traditional rotor, and satisfies the three indicators of reliability, pumping speed and compression ratio through the improvement of parameters such as the number of stages, inclination, and thickness of the blades. as follows:

[0012] figure 1 A three-dimensional view of the blisk rotor. Among the figure: 11 is the first-stage moving blade, 12 is the second-stage moving blade, and 13 is the third-stage moving blade.

[0013] figure 2 It is a plan view of the moving blade on the top surface of the blisk rotor. First, the cylindrical aluminum ingot is machined on a lathe into a cylinder with an outer diameter of R26. On the top surface of the cylinder, the moving blades with the vertical top facing upward are milled downward, and the angles between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com