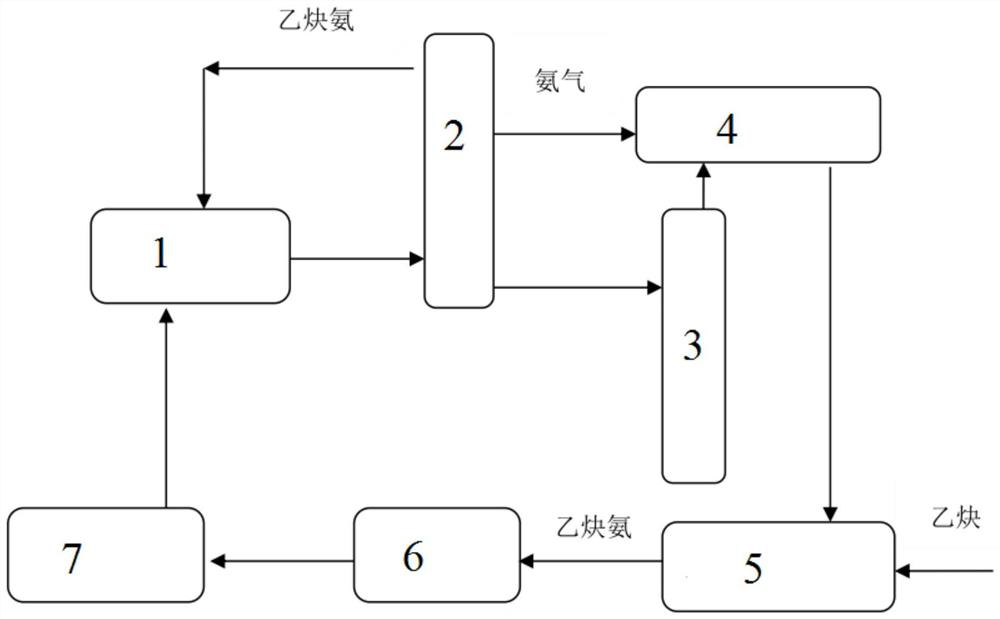

Energy-saving process for acetylenic ketone reaction device

A reaction device and acetylenic ketone technology, applied in the chemical industry, the preparation of organic compounds, sustainable manufacturing/processing, etc., to achieve the effects of increasing intake pressure, reducing power consumption, and large flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) The liquid phase stream output from the acethynone reactor contains 2500 kg of acetylene 745 kg and liquid ammonia, which is sent to the pressurized distillation column for pressure distillation.

[0043] (2) Acetylene 745 kg and liquid ammonia were 1460 kg from the acetylene mixture from the top of the pressurized distillation tower tower. Silic ammonia was 800 kg from the side line of the pressurized distillation column and the pressure was 1.2 MpAg. The tower output material of the pressurized distillation column is sent to the normal pressure distillation column, and the ammonia gas is flicked from the normal pressure distillation tower, and the pressure is 1000pAg.

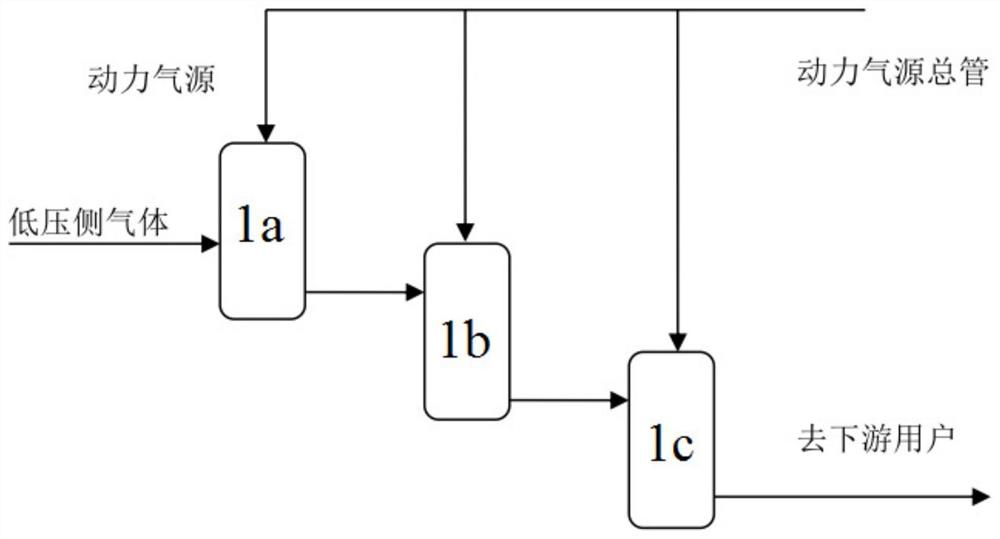

[0044] (3) The output material of the normal pressure rectification column is sent to the primary pressure lifter, from the liquid ammonia from the side line of the pressurized distillation column as the power source, the output stream of the normal pressure rectification column (evaporated ammonia) Ga...

Embodiment 2

[0046] (1) The liquid phase stream output from the acethynylide reaction contains 260 kg of acetylene 75 kg and liquid ammonia, which is charged to the pressurized rectification column for pressurization.

[0047] (2) Acetylene 75 kg and liquid ammonia were 125 kg from the acetylene mixture from the top of the pressurized distillation tower. Silic ammonia was 110kg from the side line of the pressurized distillation column, and the pressure was 1.3 MpAg. The tower output material of the pressurized rectification column is sent to the normal pressure distillation column, and 25 kg is flicked from the normal pressure distillation tower, and the pressure is 1000pAg.

[0048] (3) The output material of the normal pressure rectification column is sent to the primary pressure lifter, from the liquid ammonia from the side line of the pressurized distillation column as the power source, the output stream of the normal pressure rectification column (evaporated ammonia) Gas) is blended. The ...

Embodiment 3

[0050] (1) The liquid phase stream output from the acethynone reactor contains 150 kg and liquid ammonia 550 kg, which is sent to the pressurized rectification column for pressurization.

[0051] (2) Acetylene 150 kg and liquid ammonia 260 kg from the acetylene mixture from the top of the pressurized distillation tower. Silic ammonia 220kg from the side line of the pressurized rectification column, pressure 1.5 MpAg. The tower output material of the pressurized rectification column is sent to the normal pressure rectification column, and the ammonia gas is 70 kg from the normal pressure distillation tower, and the pressure is 2000PAG.

[0052] (3) The output material of the normal pressure rectification column is sent to the primary pressure lifter, from the liquid ammonia from the side line of the pressurized distillation column as the power source, the output stream of the normal pressure rectification column (evaporated ammonia) Gas) is blended. The ammonia pressure output from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com