Micro-titanium alloying Q355B medium-thickness steel plate and low-cost production method therefor

A technology of micro-titanium alloy and production method, which is applied in the field of iron and steel metallurgy, can solve the problems that the blank affects the continuous production rhythm, etc., and achieve the effects of improving internal quality, promoting further refinement of the structure, improving rolling efficiency and controlling the uniformity of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

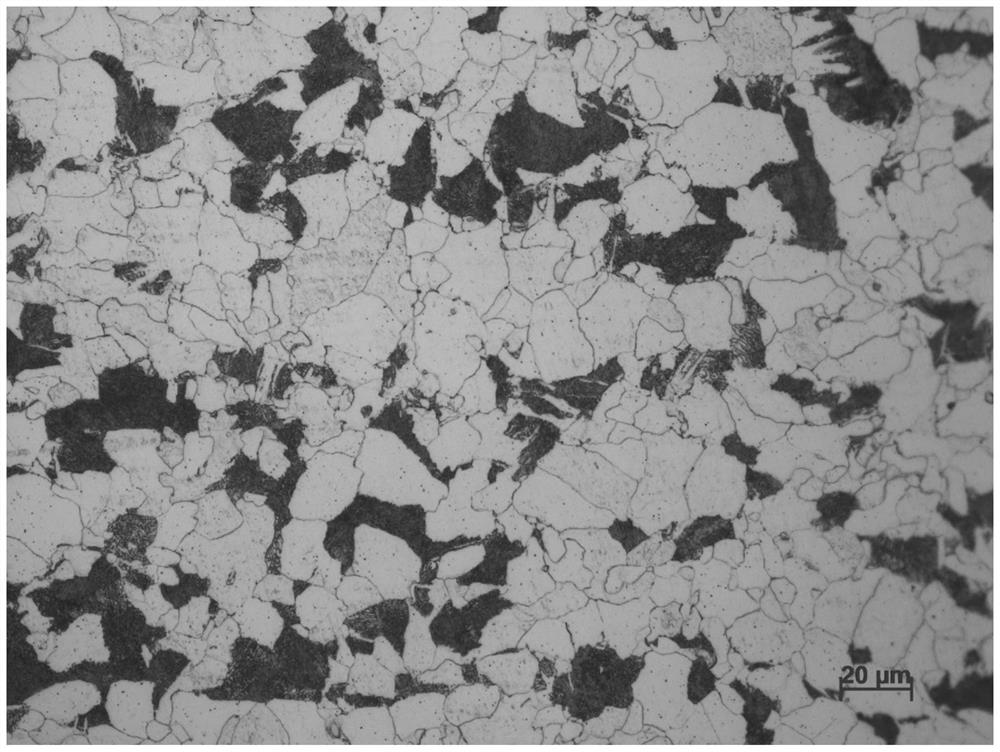

Embodiment 1

[0021]In this embodiment, the thickness of the micro-titanium alloyed Q355B medium-thick steel plate is 32 mm, and its chemical composition according to the mass fraction is as follows: C: 0.16%, Si: 0.19%, Mn: 1.52%, Al: 0.038%, Ti: 0.029%, Cr: 0.03%, P: 0.009%, S: 0.002%, N: 0.0034%, the rest is iron and inevitable impurity elements, of which Ceq: 0.41%.

[0022]The low-cost production method of the above-mentioned micro-titanium alloyed Q355B medium-thick steel plate, the steps are as follows: preparing the steel composition according to the mass percentage, hot metal KR pre-desulfurization, converter smelting, LF refining, soft stirring, slab continuous casting, slab reheating, Rough rolling, finishing rolling, rapid cooling of steel plate, hot steel straightening, upper cooling bed cooling, shearing, storage, among which after KR desulfurization treatment, the S content of molten iron is 0.006%; after LF refining treatment, the S content of molten steel is 0.002 %; soft stirring t...

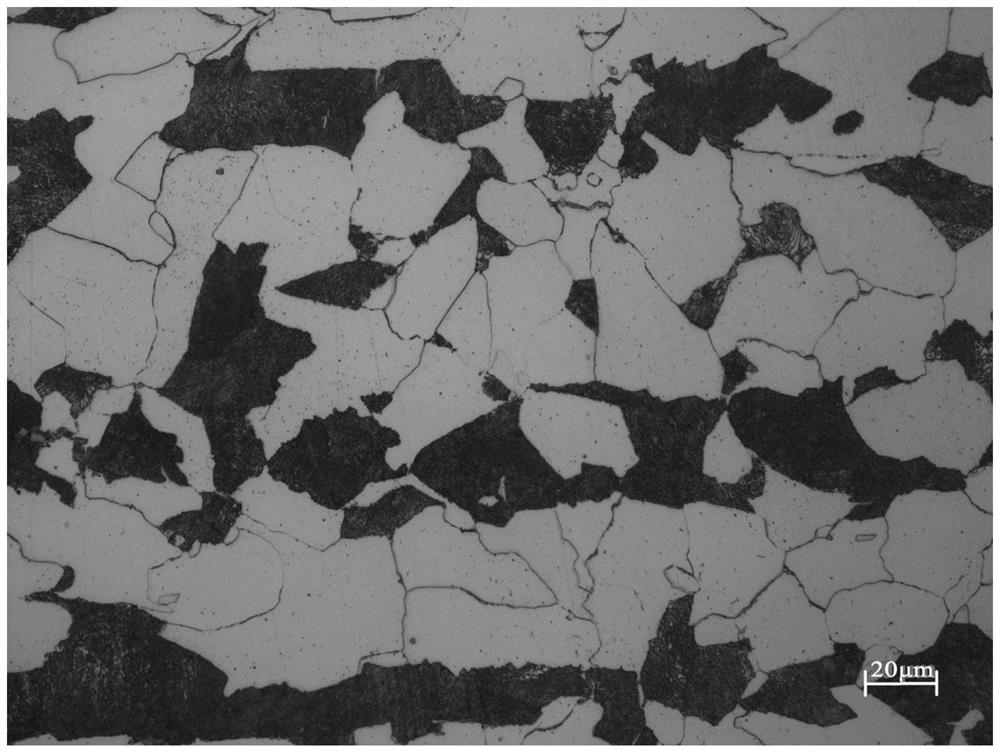

Embodiment 2

[0024]In this embodiment, the thickness of the micro-titanium alloyed Q355B medium-thick steel plate is 34 mm, and its chemical composition according to the mass fraction is as follows: C: 0.15%, Si: 0.20%, Mn: 1.49%, Al: 0.036%, Ti: 0.032%, Cr: 0.03%, P: 0.01%, S: 0.001%, N: 0.0038%, the rest is iron and unavoidable impurity elements, of which Ceq: 0.40%.

[0025]The low-cost production method of the above-mentioned micro-titanium alloyed Q355B medium-thick steel plate, the steps are as follows: preparing the steel composition according to the mass percentage, hot metal KR pre-desulfurization, converter smelting, LF refining, soft stirring, slab continuous casting, slab reheating, Rough rolling, finishing rolling, rapid cooling of steel plate, hot steel straightening, upper cooling bed cooling, shearing, storage, among which after KR desulfurization treatment, the S content of molten iron is 0.006%; after LF refining treatment, the S content of molten steel is 0.002 %; soft stirring t...

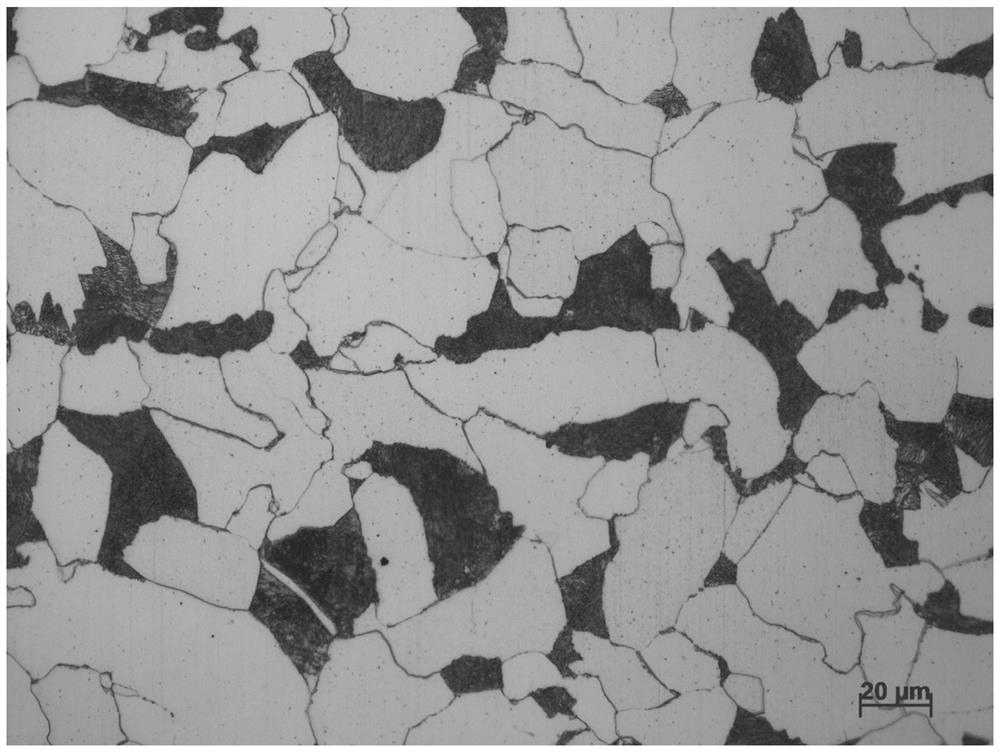

Embodiment 3

[0027]In this embodiment, the thickness of the micro-titanium alloyed Q355B medium-thick steel plate is 36 mm, and its chemical composition according to the mass fraction ratio is as follows: C: 0.16%, Si: 0.20%, Mn: 1.48%, Al: 0.030%, Ti: 0.031%, Cr: 0.02%, P: 0.01%, S: 0.001%, N: 0.0035%, the rest is iron and inevitable impurity elements, of which Ceq: 0.41%.

[0028]The low-cost production method of the above-mentioned micro-titanium alloyed Q355B medium and thick steel plate, the steps are as follows: preparing the steel composition according to the mass percentage, hot metal KR pre-desulfurization, converter smelting, LF refining, soft stirring, slab continuous casting, slab reheating, Rough rolling, finishing rolling, steel plate rapid cooling, steel plate hot leveling, upper cooling bed cooling, shearing, storage, in which after KR desulfurization treatment, the S content of molten iron is 0.005%; after LF refining treatment, the S content of molten steel is 0.002 %; soft stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com