Medium-carbon silicon-manganese low alloy steel heat treatment process based on carbon partitioning and two-step isothermal quenching

A low-alloy steel, medium-carbon silicon-manganese technology, which is applied in the field of heat treatment technology of medium-carbon silicon-manganese low-alloy steel to achieve the effects of good comprehensive mechanical properties, improved toughness, and refined structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

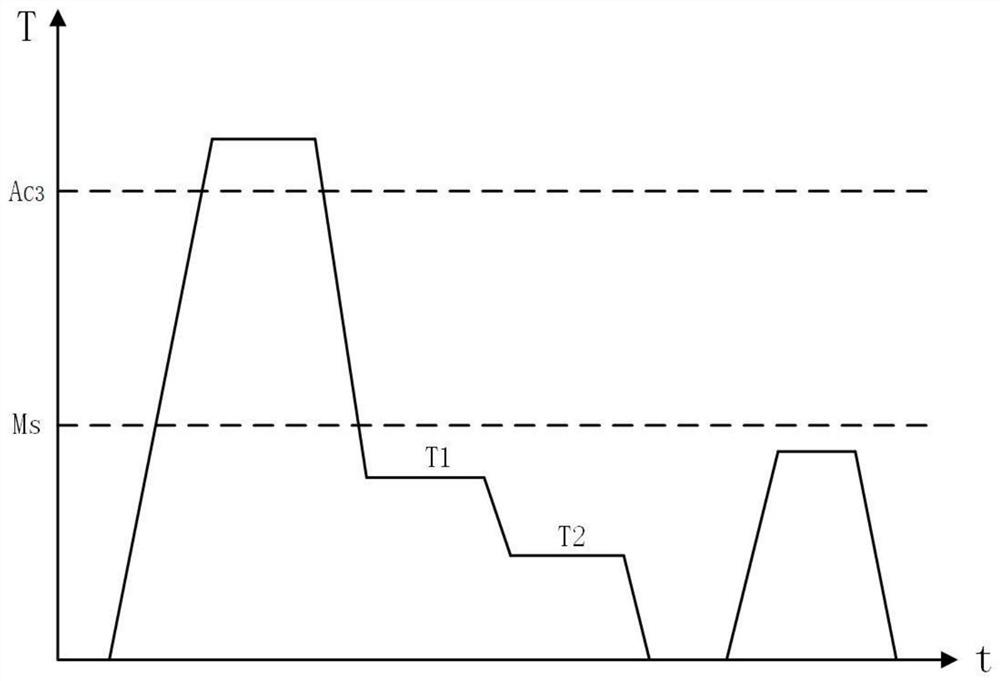

[0046] The chemical composition of medium-carbon silicon-manganese low-alloy steel is 0.28%C, 1.56%Si, 1.91%Mn, 0.83%Cr, 0.20%Ni, 0.07%V, 0.013%P, 0.004%S, and the rest is Fe, Using the German Bahr DIL805 A / D dilatometer to measure the Ms point of the carbon-silicon-manganese low-alloy steel in this composition is 316°C, the Ac3 is 852°C, and the M f It is 157°C.

[0047] (1) Forging a medium-carbon silicon-manganese low-alloy steel cast slab with a width of 100mm and a thickness of 55mm at a temperature of 1100°C into a blank with a thickness of 25mm;

[0048] (2) Obtain samples of width 10mm x thickness 10mm x length 55mm, width 6mm x thickness 4mm x length 85mm on a 25mm thick blank;

[0049] (3) Heat the sample to 900°C, keep it warm for 25 minutes, and perform austenitization treatment to obtain a fully austenitized sample;

[0050] (4) Carry out one-step isothermal quenching to the fully austenitized sample, the quenching temperature is 245°C, the quenching rate is 60°...

Embodiment 2

[0055] The chemical composition of medium-carbon silicon-manganese low-alloy steel is 0.32%C, 1.45%Si, 1.80%Mn, 1.02%Cr, 0.18%Mo, 0.10%Ni, 0.05%V, 0.06%Nb, 0.015%P, 0.005% S, the rest is Fe, the measured Ms point of steel with this composition is 300°C, Ac3 is 848°C, M f It is 141°C.

[0056] Except that the quenching temperature of one-step austempering in (4) is 261°C, the volume fraction of martensite in the obtained phase microstructure is a medium-carbon silicon-manganese low-alloy steel with a volume fraction of 35%, and the isothermal time is 60min;

[0057] (5) The quenching temperature of the second step of isothermal quenching is 200°C, and the isothermal time is 60min;

[0058] All the other are identical with embodiment 1.

[0059] The medium-carbon silicon-manganese low-alloy steel processed by the heat treatment process described in this embodiment: the tensile strength is 1582MPa, the elongation is 20.2%, the impact energy of the U-shaped notch sample reaches ...

Embodiment 3

[0061] The chemical composition of medium-carbon silicon-manganese low-alloy steel is 0.37%C, 1.86%Si, 1.03%Mn, 1.69%Cr, 0.01%P, 0.005%S, and the rest is Fe. The Ms point of the composition steel is measured is 308°C, Ac3 is 848°C, M f It is 145°C.

[0062] Except that the quenching temperature of one-step austempering in (4) is 265°C, the volume fraction of martensite in the obtained phase microstructure is a medium-carbon silicon-manganese low-alloy steel with a volume fraction of 38%, and the isothermal time is 45min;

[0063] (5) The quenching temperature of the second step of isothermal quenching is 230°C, and the isothermal time is 120min;

[0064] All the other are identical with embodiment 1.

[0065] The medium-carbon silicon-manganese low-alloy steel processed by the heat treatment process described in this embodiment: the tensile strength is 1605MPa, the elongation is 21.8%, the impact energy of the U-shaped notch sample reaches 102J, and the XRD is used to measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com