High and low temperature combined cycle engine

A combined cycle, high and low temperature technology, used in combined engines, engine components, combustion engines, etc., can solve problems such as inability to stop, pollution of the environment by exhaust gas, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

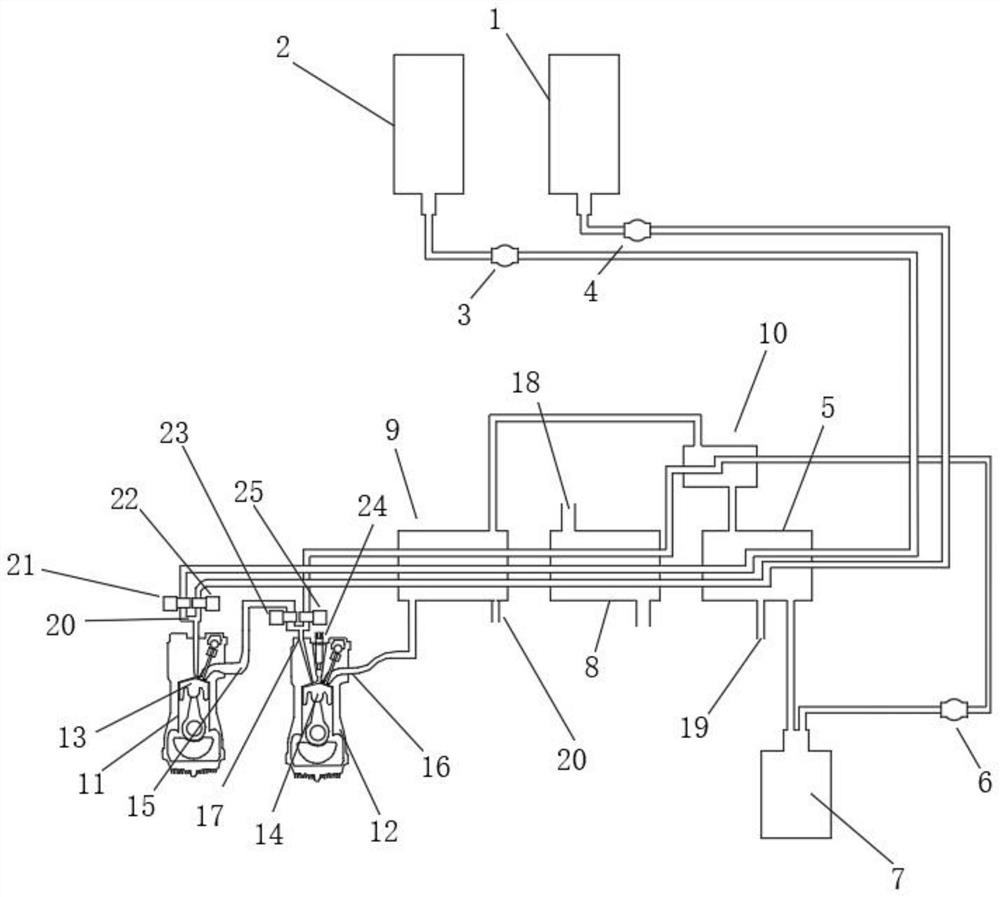

[0032] Embodiment one, see appendix figure 1 , LNG is stored in the fuel tank 1, and liquid oxygen is stored in the oxidizer tank 2. When the engine is working, the first cryopump 3 and the second cryopump 4 are started, and LNG and liquid oxygen are pumped into the first heat exchanger 5 to exchange heat with carbon dioxide gas, where the carbon dioxide gas is condensed into liquid and stored in liquid carbon dioxide Inside tank 7. LNG and liquid oxygen continue to enter the second heat exchanger 8, exchange heat with the air, absorb the heat in the air, cool the air, and at the same time become gaseous natural gas and gaseous oxygen or gas-liquid mixture, enter the third heat exchange Device 9. In the third heat exchanger 9, the natural gas, oxygen and the high-temperature exhaust gas discharged from the second exhaust port 16 perform heat exchange, the temperature of the high-temperature gas decreases, and part of the condensed water is discharged, and the remaining carbo...

Embodiment 2

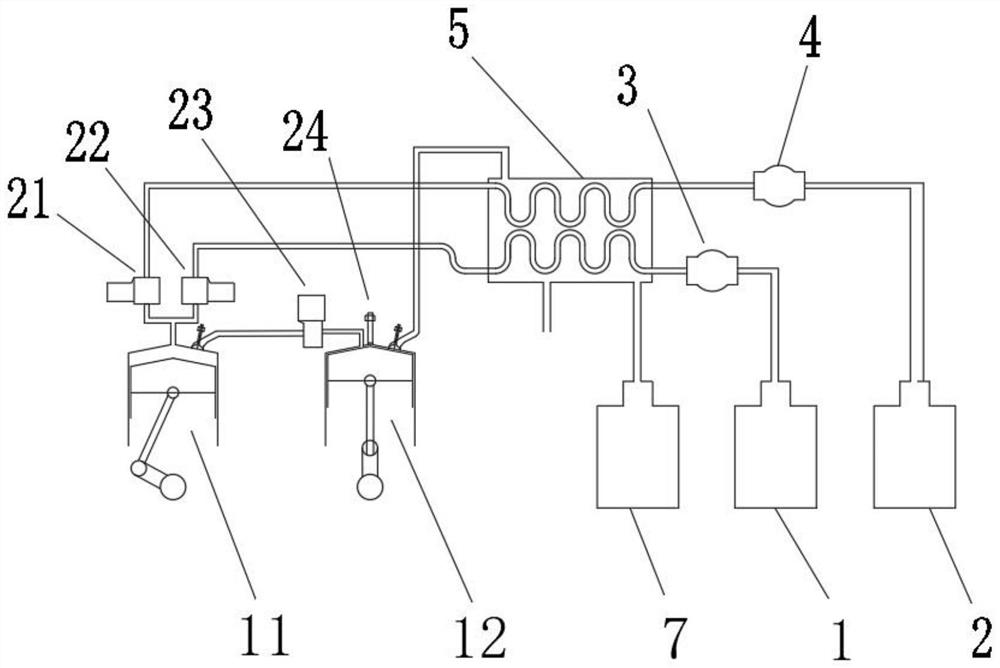

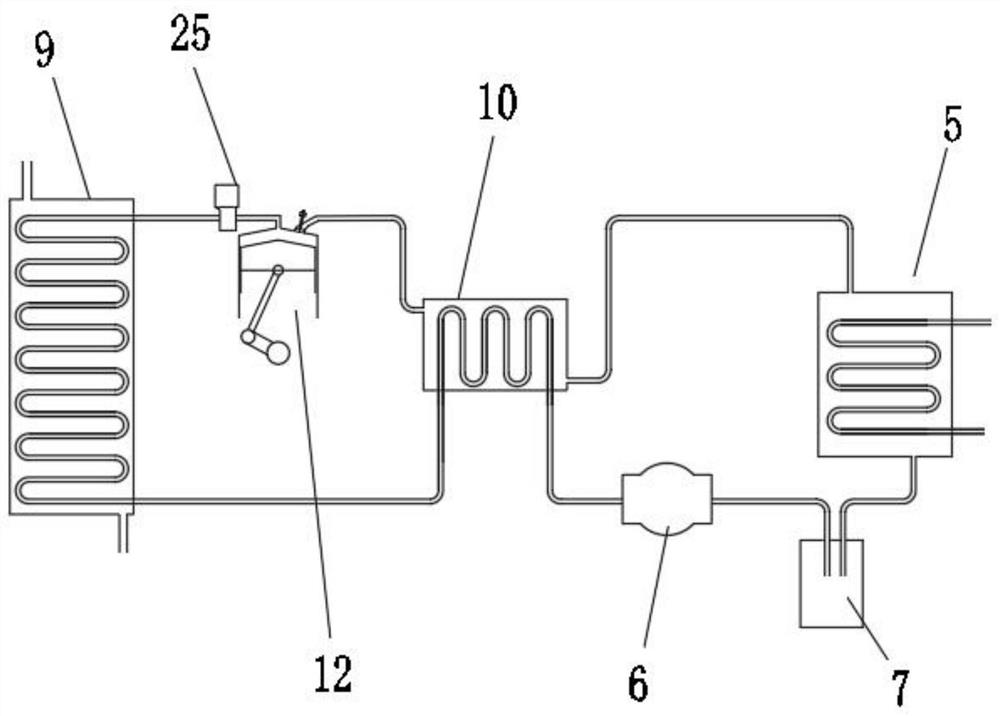

[0034] Embodiment two, such as figure 1 The invention shown here can be disassembled into figure 2 and image 3 two parts. figure 2 It consists of half a Rankine cycle and a half Otto cycle. image 3 is a complete Rankine cycle. image 3 The loop can recurse multiple times. figure 2 , image 3 They can be combined into one system, or they can form separate systems.

[0035] image 3 The Rankine cycle uses carbon dioxide as the working medium because carbon dioxide has a moderate boiling point, is easy to obtain, and is safe. The condensing agent can use liquid oxygen, LNG, liquid nitrogen and other gases with lower boiling points.

[0036] Combining Embodiment 1 and Embodiment 2, the present invention uses pure oxygen for combustion, which not only improves the combustion temperature and combustion speed, but also improves the combustion efficiency, that is, the efficiency of the engine is improved. At the same time, it reduces the emission of harmful gases such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com